Transverse moving mechanism of portal crane

A technology of gantry crane and traverse mechanism, which is applied in the directions of traveling mechanism, mechanical equipment, transmission parts, etc., can solve the problems of unfavorable safety, reduced equipment service life, damage of guide rails and clamping wheels, etc., to avoid inconsistent moving distance, The effect of preventing rainwater erosion and ensuring service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

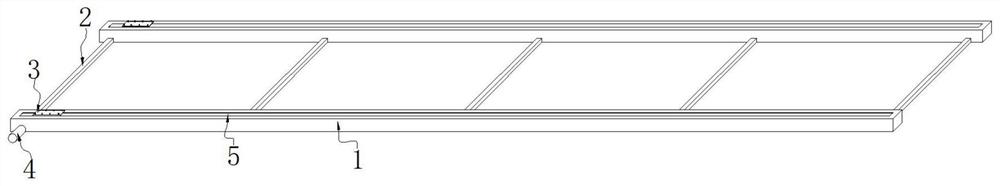

Image

Examples

Embodiment approach

[0030] As a preferred embodiment of the present invention, the inner side of the clamping plate 11 is provided with internal threads, and the outer side of the screw rod 9 is provided with external threads, and the internal threads cooperate with the external threads.

[0031] As a preferred embodiment of the present invention, the inner sides of both ends of the clamping chamber 10 are bonded with sealing sleeves, and the sealing sleeves are set on the outer side of the screw rod 9. When the screw rod 9 rotates, the screw rod 9 passes through the screw thread. Push the clamping plate 11 to move laterally, and then make the clamping plate 11 push the bracket 6 to move laterally through the clamping cavity 10, the bracket 6 moves on the top of the guide rail 7 through the card wheel 8, and then drives the gantry crane through the support 3 to move laterally, When the gantry crane and its hoisted weights cause a slight depression in the foundation, the support 3 is pushed downwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com