Automatic tablet counting device for filling clinopodium polycephalum tablets

A technology for breaking blood flow tablets and filling, which is applied in the field of automatic tablet counting devices for filling blood flow breaking tablets, which can solve the problems of low efficiency and labor consumption, achieve high material distribution efficiency, improve efficiency and avoid filling shortage effect of material phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

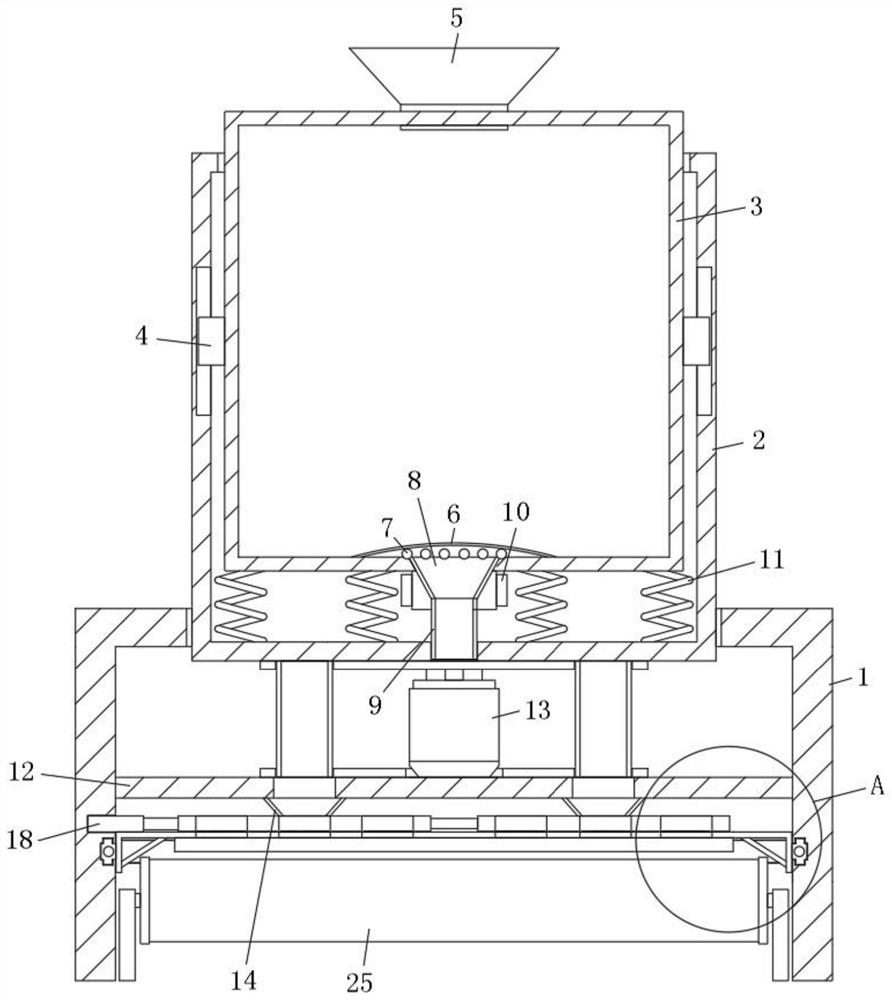

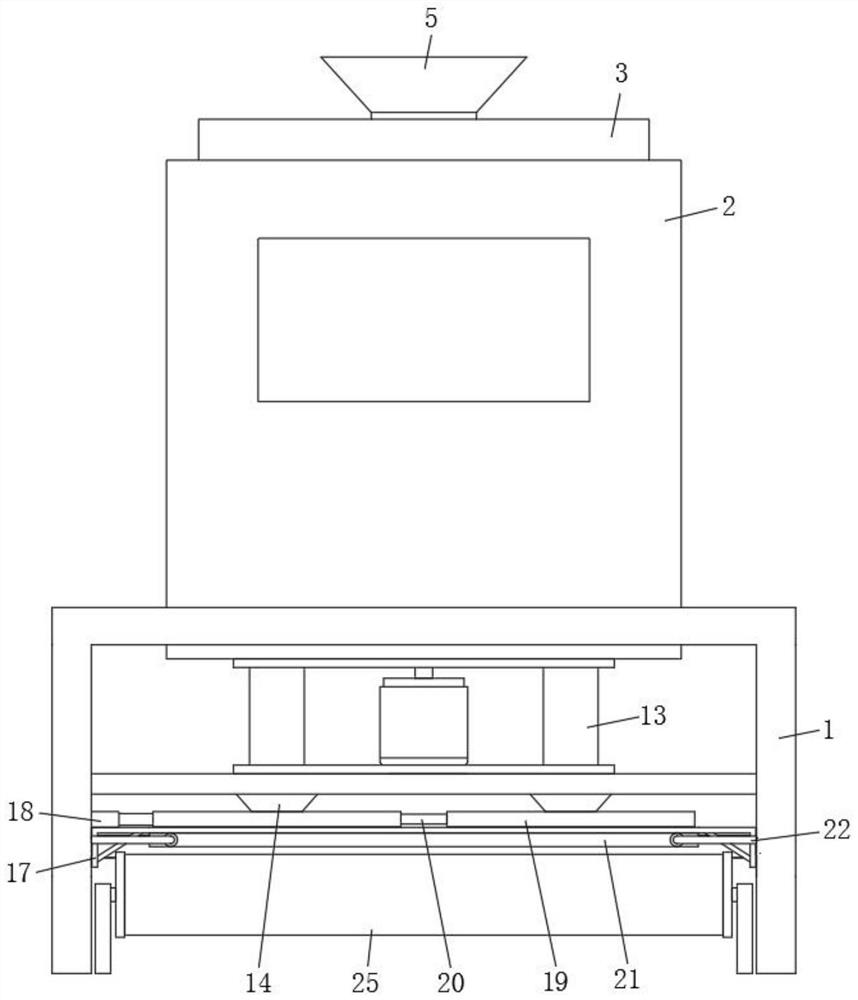

[0033] refer to Figure 1-6, an automatic chip counting device for filling broken blood flow slices, comprising a working frame 1, a circular hole is opened on the top surface of the working frame 1, a limiting cylinder 2 is fixed on the inner wall of the circular hole, and the inner wall of the limiting cylinder 2 is slidingly connected with a branch The material cylinder 3, the top of the material distribution cylinder 3 extends to the outside of the limit cylinder 2 and is connected with the feeding hopper 5, the middle part of the bottom surface of the material distribution cylinder 3 is fixed with an arc-shaped plate 6, and the inner side of the material distribution cylinder 3 is equipped with a condensation pipe 7, and the material distribution There is a lower hopper 8 running through the inner bottom surface of the cylinder 3, and the lower side of the lower hopper 8 is fixed with a lower material tube 9, and the inner bottom surface of the working frame 1 is also prov...

Embodiment 2

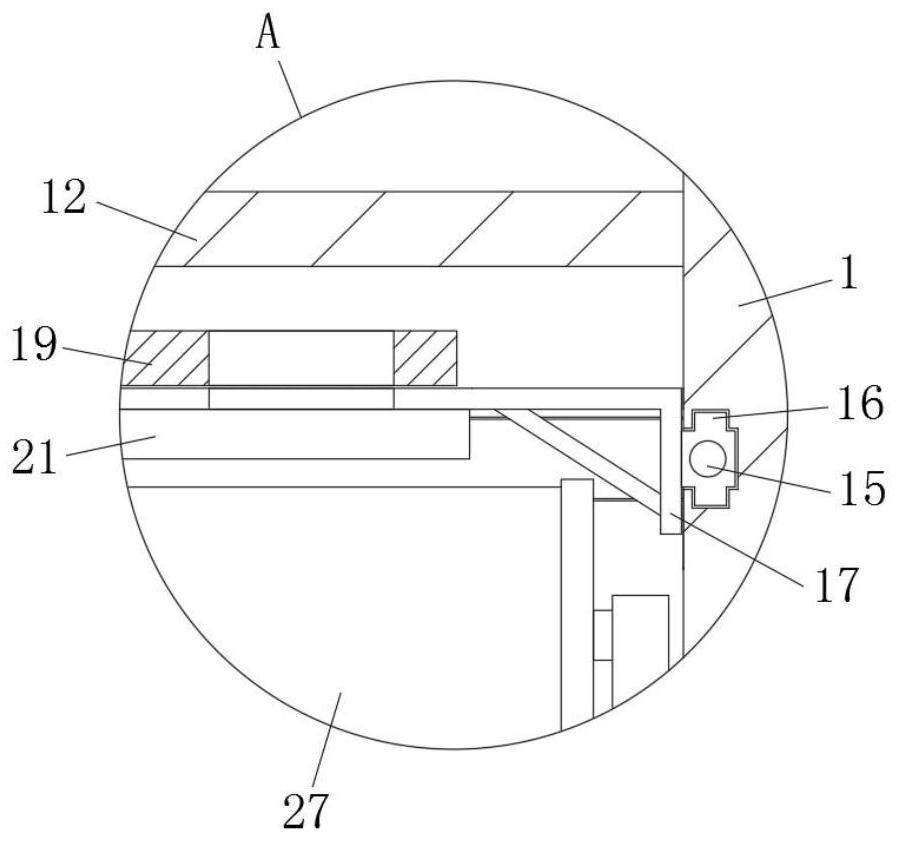

[0035] Such as figure 1 and 6 As shown, this embodiment is basically the same as Embodiment 1. Preferably, both sides of the bottom surface of the horizontal frame 17 are provided with bar-shaped grooves, and bar-shaped blocks 28 are fixed on both sides of the baffle plate 21, and the bar-shaped blocks 28 are slidably connected to the bar-shaped In the groove, a resetting elastic rope 29 is fixed between the strip block 28 and the front side wall of the strip groove.

[0036] Both the bar block 28 and the bar slot are T-shaped, and the bar block 28 is slidably connected in the bar slot, and two resetting elastic ropes 29 are arranged and symmetrically distributed on both sides of the bar slot.

[0037] In this embodiment, after the baffle plate 21 moves after the collision to complete the filling and unloading, the baffle plate 21 can be pulled forward to complete the reset under the action of the reset elastic rope 29 at this time, so as to realize the automatic barrier afte...

Embodiment 3

[0039] Such as figure 1 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the outer walls on both sides of the material distribution cylinder 3 are fixed with limiting blocks 4, the inner walls on both sides of the limiting cylinder 2 are provided with limiting grooves, and the limiting blocks 4 are all slidably connected. in the limit slot.

[0040] In this embodiment, the distributing cylinder 3 and the limiting cylinder 2 are connected through a sliding limit block 4 , so that the vibrating up and down of the distributing cylinder 3 is more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com