Jet printing diamond painting structure and diamond painting ground color particles

A diamond painting and particle technology, applied in the field of handicrafts, can solve problems such as blurring, blurring, halo, etc., and achieve the effect of reasonable layout, clear positioning, and color saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

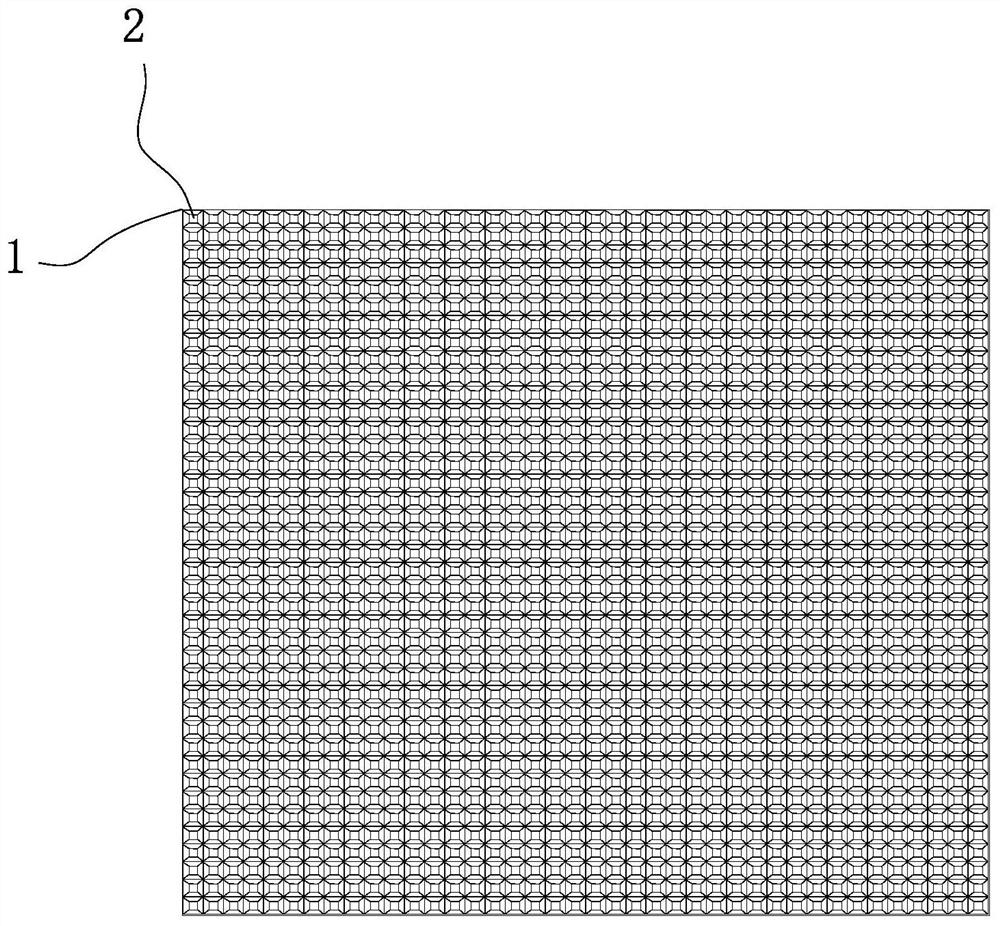

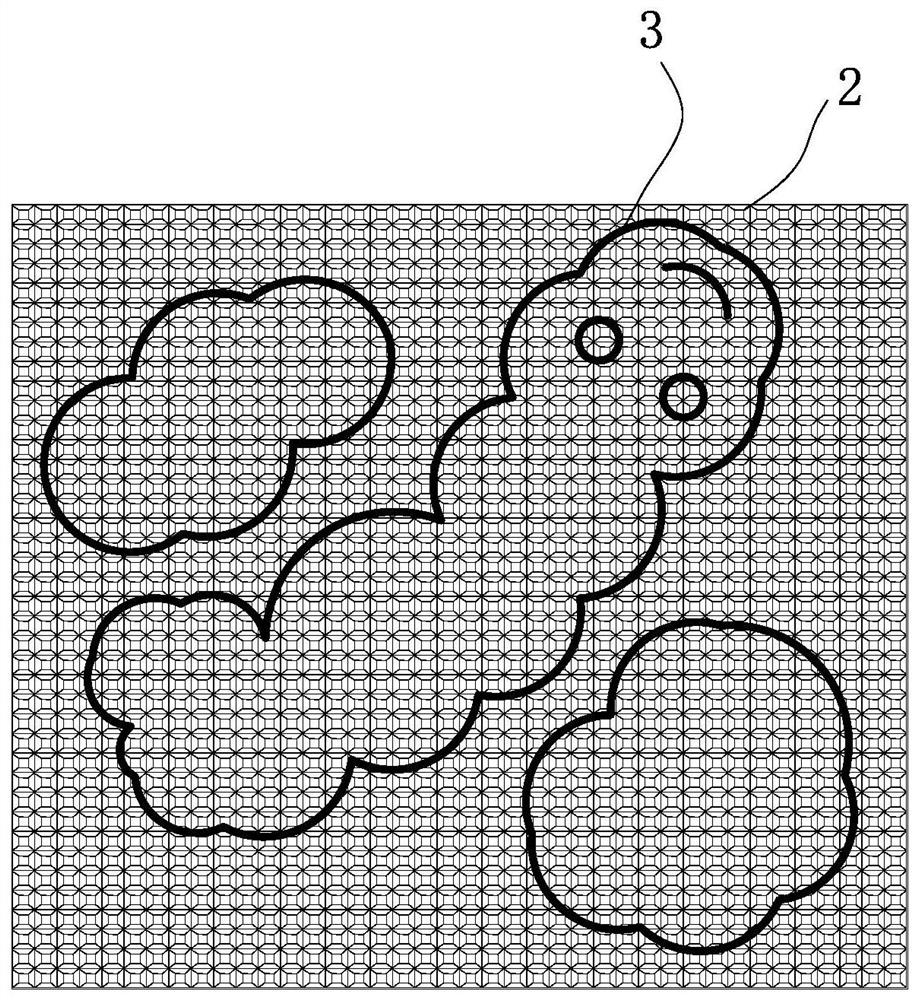

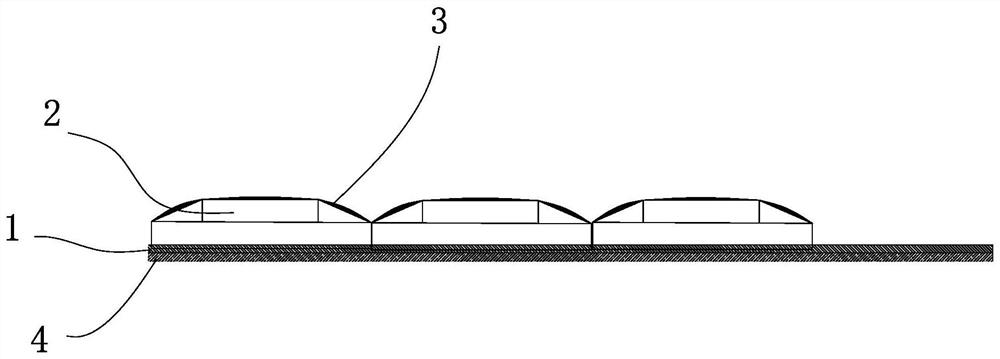

[0033] The four-layer structure of the jet-printed diamond painting structure, figure 1 Shown includes a substrate for laying particles 2, the substrate is in a soft state, the substrate includes a bottom layer 4 and figure 2 Adhesion layer 1 shown, image 3 The shown bottom layer 4 is a fabric, the adhesive layer 1 is a colloidal substance, and the diamond painting includes the bottom layer 4, the adhesive layer 1, the opaque white particle layer 2 and the color layer 3 from bottom to top.

[0034] Preferably, the adhesive layer 1 can be a thick hot melt adhesive, and the particles 2 can be embedded in the hot melt adhesive after the hot melt adhesive is softened at a low temperature, and at the same time can be bonded.

[0035] A more preferred thickness of the adhesive layer 1 is between 0.5-5mm. The fabric of the bottom layer 4 can increase the tensile tearing resistance of the adhesive layer 1 .

[0036] The particles 2 can be arranged to form a layer. The particles 2...

Embodiment 2

[0041] During three-layer structure, compared with embodiment 1, Figure 4 Shown with color layer 3 removed. From bottom to top, it includes the bottom layer 4, the adhesive layer 1, and the opaque white particle layer 2. The particle 2 is white and used as the background color for printing. The three-layer structure can be sold as a painting material. Customers can make white particles 2 by themselves. Color printing is performed on the layer by printing equipment.

Embodiment 3

[0043] Figure 5 As shown, when the two-layer structure is compared with Example 1, it includes an adhesive layer 1 and an opaque white particle 2 layer from bottom to top. The particle 2 is white and is used as a background color for printing. Customers can use the adhesive layer 1 sticks to the cloth, sticks to the wall, sticks to the picture frame 5.

[0044] The two-layer structure can be sold as the material of the painting, and the customer can print the color on the second layer of white particles by printing equipment, and then paste it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com