Manufacturing method of antibacterial packaging material for seed storage

A technology of packaging materials and production methods, applied in the field of storage and packaging, to achieve the effects of avoiding high costs, lasting antibacterial time, and being easy to put into industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for making an antibacterial packaging material for seed storage, specifically comprising the following steps:

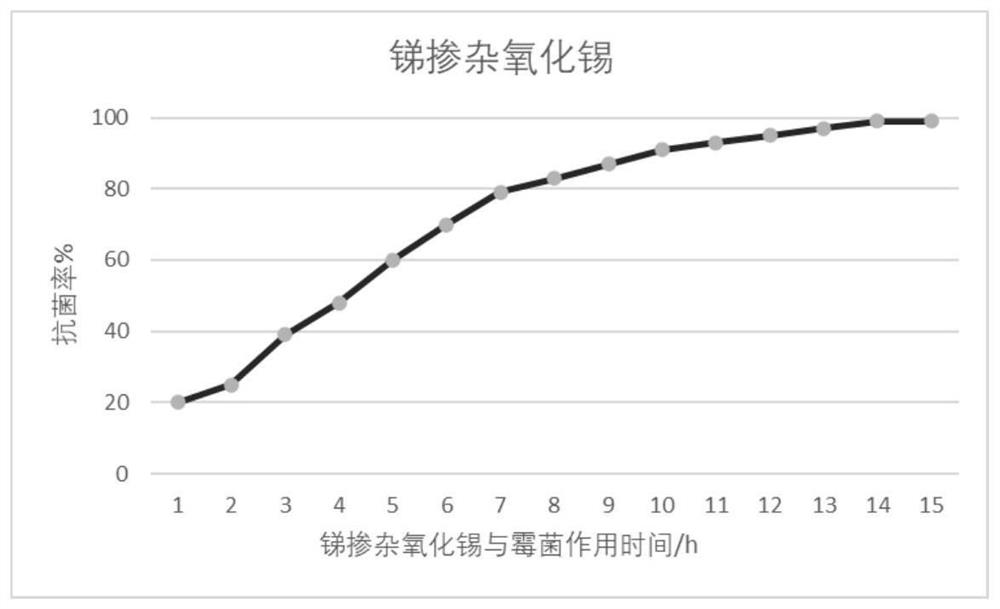

[0033] Add tris(2,4-pentanedionate) indium and bis(2,4-pentanedionate) tin dichloride with a total molar mass of 1 mmol to 17.5 mL of Remove it from the n-butanol solution, ultrasonically disperse it at room temperature for 15 minutes, add it into a 50mL polytetrafluoroethylene-lined reaction kettle, and heat it at a constant temperature of 150°C for 48 hours; take it out and place it at room temperature, wash it with ethanol three times, and then Wash once with deionized water, place it in a vacuum oven at 60°C and dry for 8 hours to make antimony-doped tin oxide nanoparticle material;

[0034] Add antimony chloride and bis(2,4-pentanedionate) tin dichloride with a total molar mass of 1 mmol to 5% doping ratio of antimony atoms into 17.5 mL of n-butanol solution. After ultrasonic dispersion for 15 minutes, add it to a 50mL polytetrafluoroethylene-li...

Embodiment 2

[0041] A method for making an antibacterial packaging material for seed storage, specifically comprising the following steps:

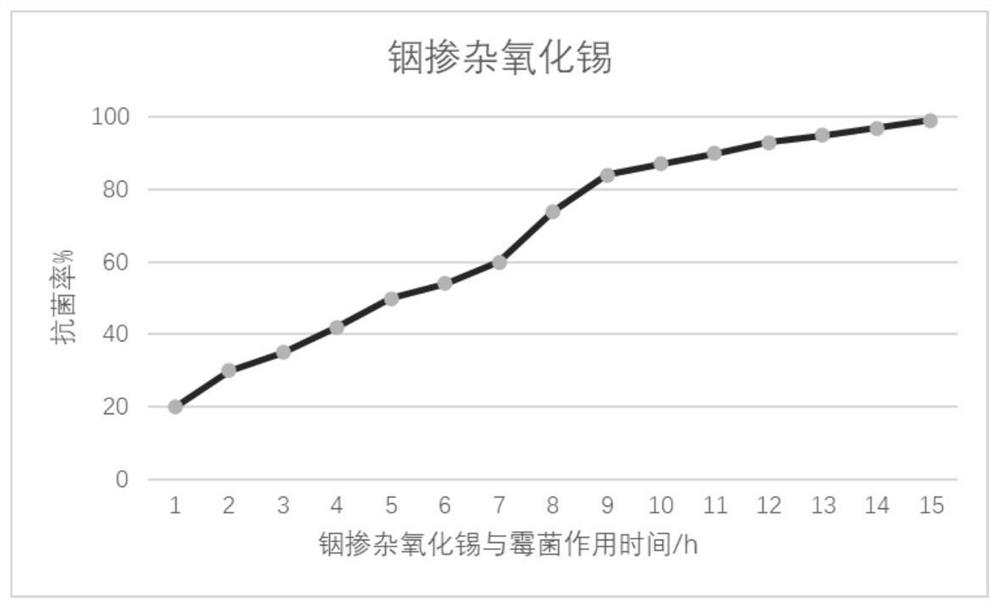

[0042] Add tris(2,4-pentanedionate) indium and bis(2,4-pentanedionate) tin dichloride with a total molar mass of 1 mmol to 17.5 mL of Remove it from the n-butanol solution, ultrasonically disperse it at room temperature for 20min, add it into a 50mL polytetrafluoroethylene-lined reaction kettle, and heat it at a constant temperature of 170°C for 48h; take it out and place it at room temperature, wash it with ethanol three times, and then Wash once with deionized water, and dry in a vacuum oven at 60°C for 10 hours;

[0043] Add antimony chloride and bis(2,4-pentanedionate) tin dichloride with a total molar mass of 1 mmol to 17.5 mL of n-butanol solution at an antimony atom doping ratio of 8%. After ultrasonically dispersing for 20 minutes, add it to a 50mL polytetrafluoroethylene-lined reactor and heat at a constant temperature of 170°C for 48 hours;...

Embodiment 3

[0050] A method for making an antibacterial packaging material for seed storage, specifically comprising the following steps:

[0051]Add tris(2,4-pentanedionate) indium and bis(2,4-pentanedionate) tin dichloride with a total molar mass of 1 mmol to 10 mL of n- Remove it from the butanol solution, ultrasonically disperse it at room temperature for 30 minutes, then add it to a 50mL polytetrafluoroethylene-lined reaction kettle, and heat it at a constant temperature of 200°C for 24 hours; take it out and place it at room temperature, wash it with ethanol three times, and then use Wash once with deionized water and dry in a vacuum oven at 60°C for 4 hours;

[0052] Add antimony chloride and bis(2,4-pentanedionate) tin dichloride with a total molar mass of 1 mmol to 10 mL of n-butanol solution at an antimony atom doping ratio of 10%. After ultrasonic dispersion for 30min, add it to a 50mL polytetrafluoroethylene-lined reaction kettle, and heat it at a constant temperature of 200°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com