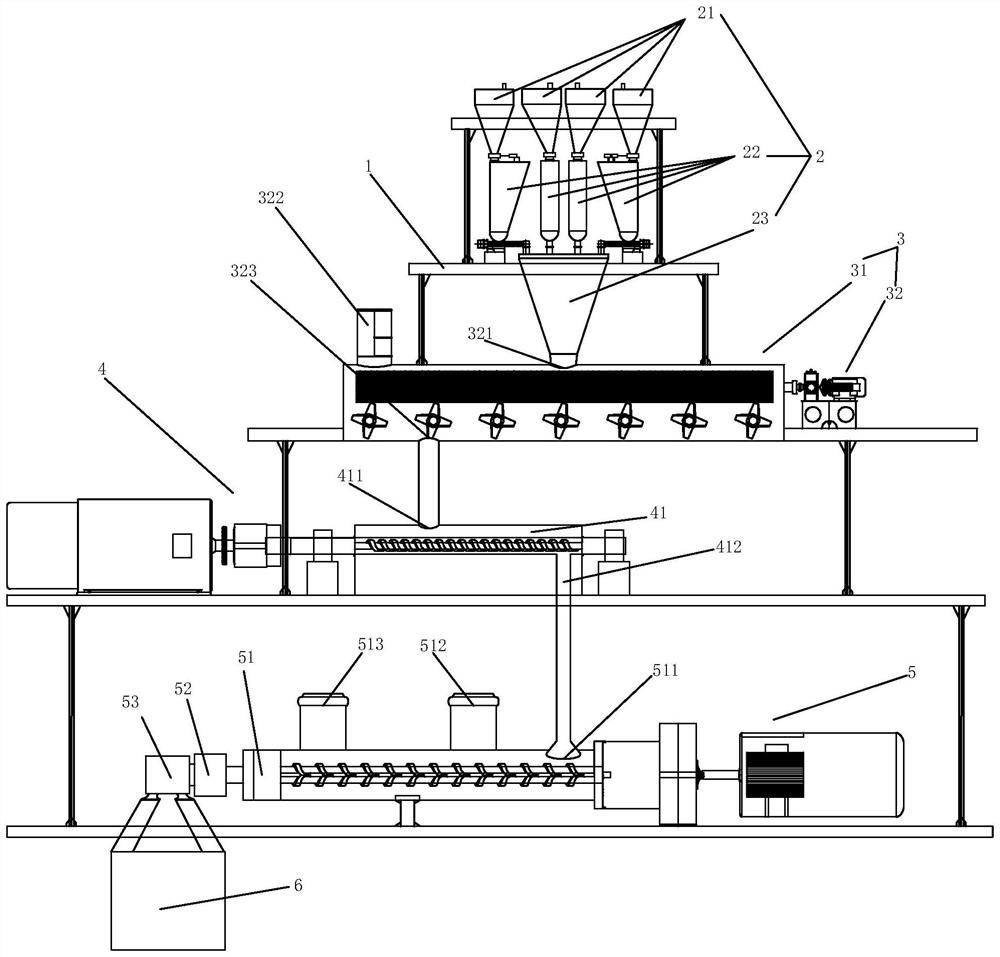

Multifunctional double-order melting method efficient production equipment and process

A technology of production equipment and production process, which is applied in the field of high-efficiency production equipment and process of multi-functional two-stage melting method, can solve the problems of inaccurate weighing of weighing devices, and achieve the advantages of reducing molecular structure changes of materials, accurate raw materials, and saving labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

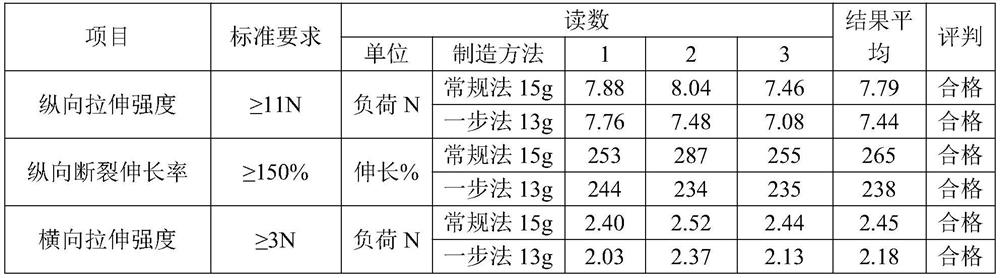

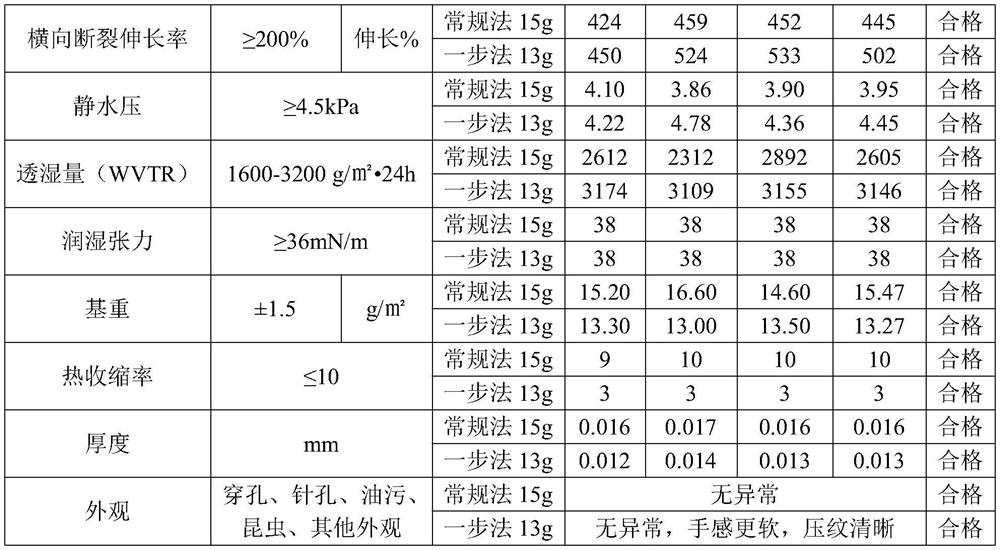

Embodiment 1

[0042] A multifunctional two-stage melting method production process, using the above-mentioned multifunctional two-stage melting method high-efficiency production equipment, comprising the following steps:

[0043] Step 1: Raw material preparation: the following components metallocene linear low density polyethylene, low density high pressure polyethylene coating material, high density polyethylene, blocking agent, antioxidant, wetting agent, titanium dioxide, zinc stearate , Calcium carbonate is added to the feeding mechanism;

[0044] Step 2: Weighing raw materials: The feeding mechanism weighs according to the following parts by weight: 30 parts of metallocene linear low-density polyethylene, 3 parts of low-density high-pressure polyethylene coating material, 2 parts of high-density polyethylene, and 0.5 parts of anti-blocking agent , 0.2 parts of antioxidant, 0.1 part of wetting agent, 0.5 parts of titanium dioxide, 0.5 parts of zinc stearate, 50 parts of calcium carbonat...

Embodiment 2

[0050] A multifunctional two-stage melting method production process, using the above-mentioned multifunctional two-stage melting method high-efficiency production equipment, comprising the following steps:

[0051] Step 1: Raw material preparation: the following components metallocene linear low density polyethylene, low density high pressure polyethylene coating material, high density polyethylene, blocking agent, antioxidant, wetting agent, titanium dioxide, zinc stearate , Calcium carbonate is added to the feeding mechanism;

[0052] Step 2: Weighing raw materials: The feeding mechanism weighs according to the following parts by weight: 40 parts of metallocene linear low-density polyethylene, 7 parts of low-density high-pressure polyethylene coating material, 5 parts of high-density polyethylene, and 0.8 parts of anti-blocking agent , 0.6 parts of antioxidant, 0.3 parts of wetting agent, 1 part of titanium dioxide, 0.7 parts of zinc stearate, 53 parts of calcium carbonate,...

Embodiment 3

[0058] A multifunctional two-stage melting method production process, using the above-mentioned multifunctional two-stage melting method high-efficiency production equipment, comprising the following steps:

[0059] Step 1: Raw material preparation: the following components metallocene linear low density polyethylene, low density high pressure polyethylene coating material, high density polyethylene, blocking agent, antioxidant, wetting agent, titanium dioxide, zinc stearate , Calcium carbonate is added to the feeding mechanism;

[0060] Step 2: Weighing raw materials: The feeding mechanism weighs according to the following parts by weight: 50 parts of metallocene linear low-density polyethylene, 10 parts of low-density high-pressure polyethylene coating material, 8 parts of high-density polyethylene, and 1 part of anti-blocking agent , 0.2 parts of antioxidant, 0.5 parts of wetting agent, 1.5 parts of titanium dioxide, 1.0 parts of zinc stearate, 55 parts of calcium carbonate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com