Tool turret with cutting scrap anti-winding and automatic cleaning functions

An automatic cleaning and turret technology, applied in the direction of tool holders, manufacturing tools, metal processing machinery parts, etc., can solve the problems of waste, cumbersome, difficult to clean, etc., and achieve the effect of reducing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

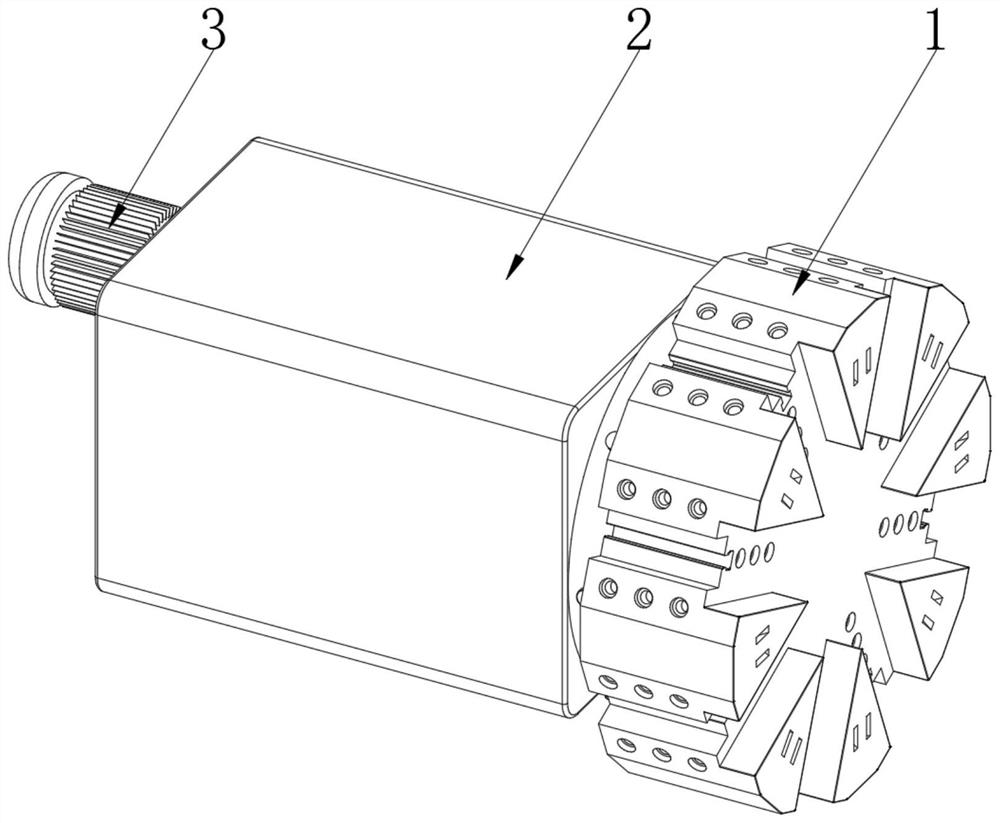

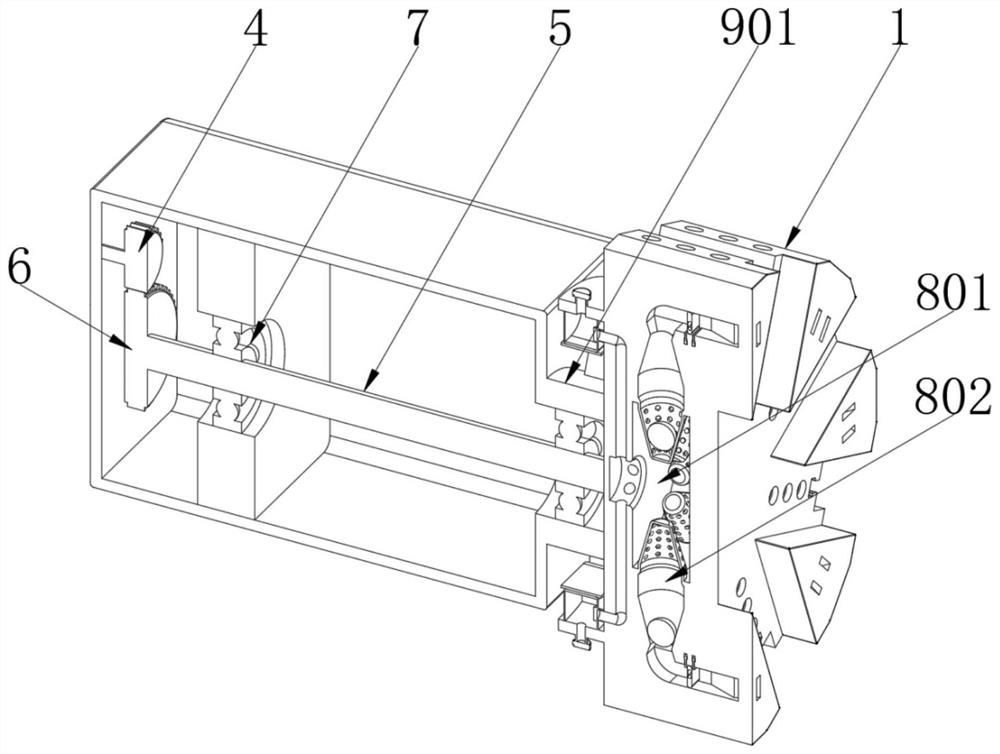

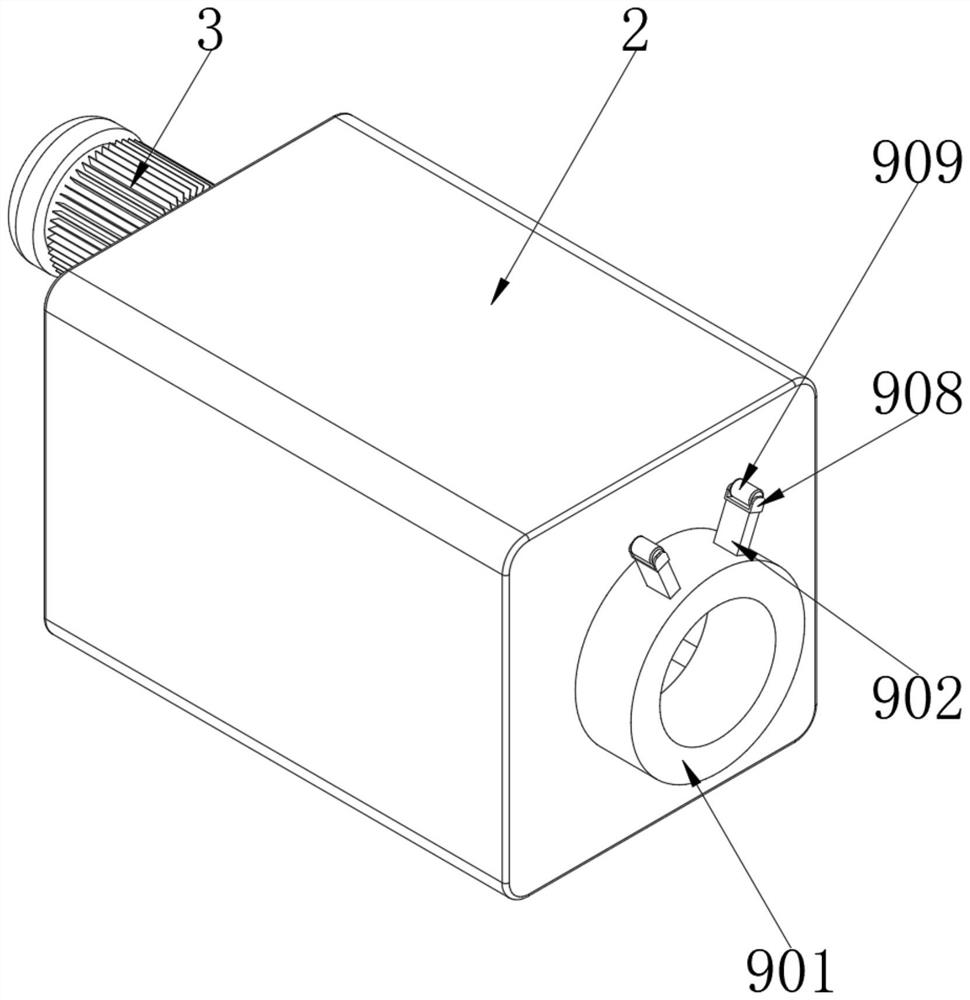

[0040] Example: such as Figure 1 to Figure 9 As shown, the present invention provides the following technical solutions, a kind of turret with chip anti-winding automatic cleaning function, including a turret base 1, a transmission box 2 is installed on the back of the turret base 1, and a drive motor 3 is installed on the transmission box 2, One end of the drive motor 3 is provided with a driving gear 4, and the transmission box 2 is internally provided with a transmission shaft 5 for driving the turret base 1 to rotate. The transmission shaft 5 is installed inside the transmission box 2 through the rotation of the bearing 7. A chip removal assembly is arranged inside the turret base 1. The chip removal assembly is used to remove the entangled and adhered waste on the surface of the tool, so as to avoid the impact of the waste on the tool. For normal cutting of the workpiece, an air supply assembly 9 is installed between the turret base 1 and the transmission box 2. The air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com