Flue gas purification system of casting blank arc angle forming device

A flue gas purification system and forming device technology, applied in the field of metallurgy, can solve the problems of low processing efficiency, large investment for electrostatic dust removal equipment, yellow smoke, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

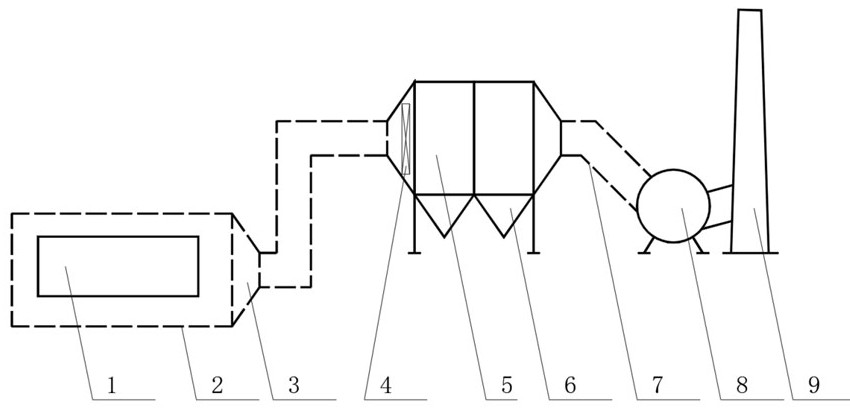

[0016] like figure 1 As shown, the system diagram of the present invention is provided, which includes main equipment such as smoke collection hood 2, smoke purification device 5 and induced draft fan 7; Pipe 7, induced draft fan 8 and chimney 9 are connected successively.

[0017] The fume collection cover 2 completely covers the billet arc corner forming device 1 and isolates the billet arc corner forming device 1 from the outside world.

[0018] The flue gas purification device 5 is an electrostatic precipitator.

[0019] A flue gas rectification device 4 is installed at the entrance of the flue gas purification device 5 .

[0020] A dust-proof hopper 6 is arranged below the flue gas purification device 5 .

[0021] Before the flue gas purification system of the above-mentioned slab arc angle forming device is put into operation, the flue gas dust content of the slab arc angle forming device is about 3g / m 3 . After the flue gas purification system of the billet arc cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com