Upper bundle steam generator cleaning system and method

A technology for steam generators and cleaning equipment, which is applied in steam generation, components of steam boilers, steam boilers, etc., and can solve problems such as difficult steam generators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

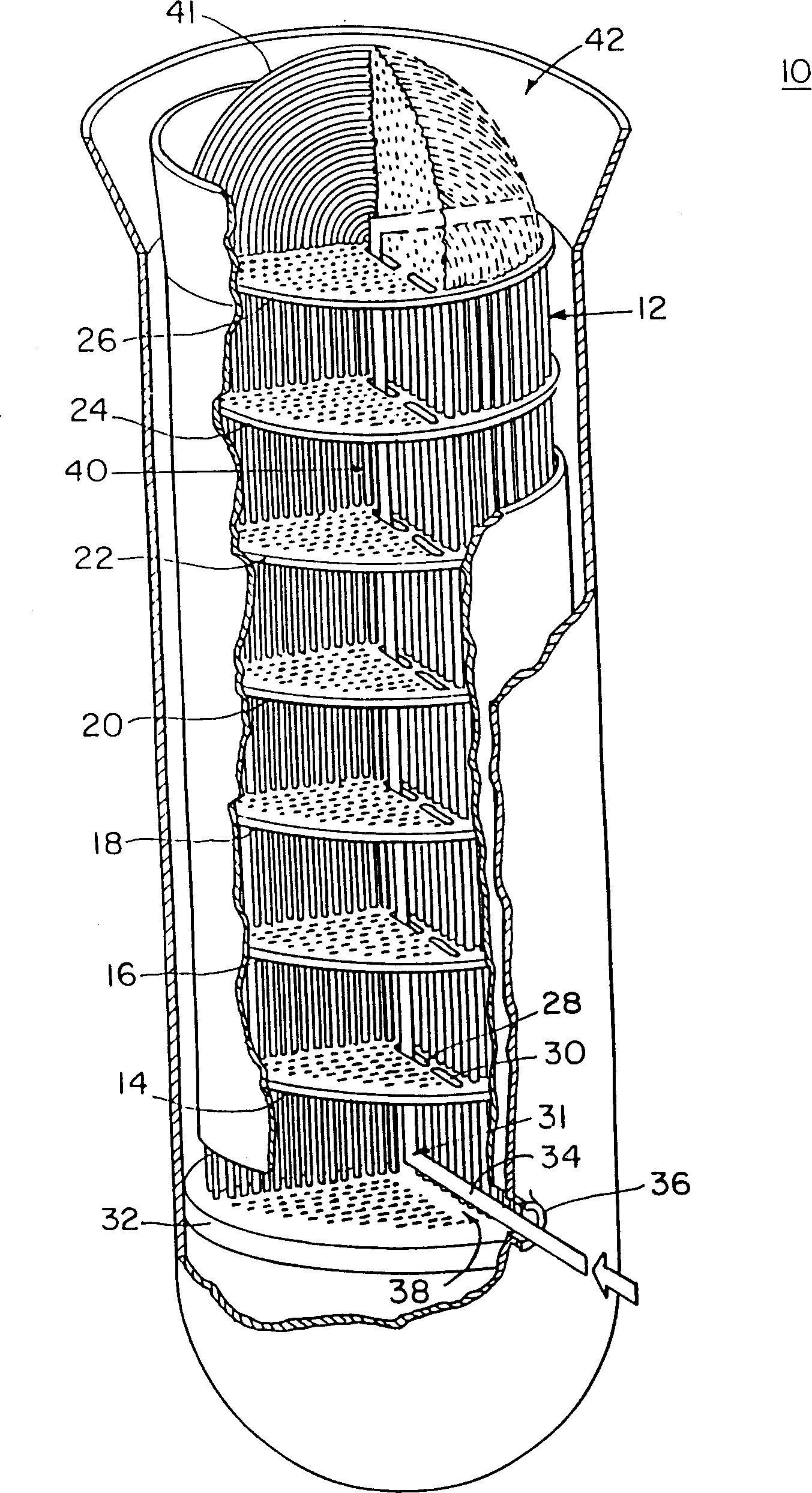

[0044] figure 1 A steam generator 10 is schematically shown comprising heat exchange tubes 12 divided into sections by tube support plates 14 , 16 , 18 , 20 , 22 , 24 and 26 . As shown in the first layer of tube support plates 14, each tube support plate includes a number of launders 28 and 30.

[0045] The W44 and W51 steam generators, designed by Westinghouse, account for the largest market share of steam generators, and the W51 is similar in size to the W44. The diameter of the tube supporting plate adopted by the W44 type steam generator is 116″, and the tube supporting plate above the heating tube partition is evenly spaced by 51a″. Two 6" diameter hand holes are provided, such as hand holes 36 at each end of a 3 1 / 2" discharge channel 38 at the level of the heater tube bulkhead 32. The support plate of each heater tube divider has three launders measuring 2-2 3 / 4″ x 15″ spaced 4″ on each side from the center tie rod 40. Align the launders with each other so that the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com