Preparation method and application of grass carp fermented soft particles based on lactobacillus

A technology of soft granules and grass carp, applied in the field of grass carp fermented soft granules based on Lactobacillus and its preparation, can solve the problems of uneven sedimentation of the starter, low water content, inappropriate pH, etc., to ensure the retention time and repair the intestines Road barrier, reducing the effect of nitrogen and phosphorus content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

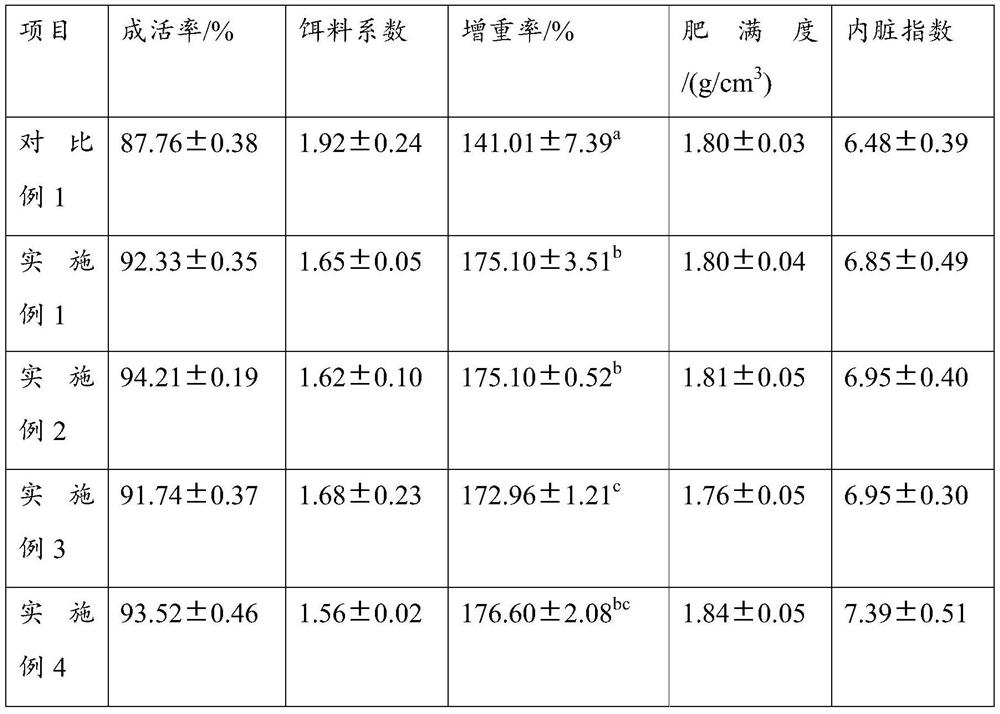

Examples

Embodiment 1

[0031] The preparation method of the grass carp fermented soft granule of the present embodiment may further comprise the steps:

[0032] (1) Mix 10g fish meal, 4g fermented soybean meal, 3g wheat bran, 5g canola meal, 3g fine bran, 2g corn bran, 1g premix, 0.05g zeolite powder, 1g calcium dihydrogen phosphate, 0.5g bentonite and 0.2 ml of bile acid, and spray condensation granulation at 40°C to obtain basic granules;

[0033] (2) Yeast, lactic acid bacteria, lactobacillus, mass concentration are 5% dendrobium pulp and mass concentration 5% fructose syrup are mixed and stirred, and fermented (moisture content control in the fermentation process is 29%, and the temperature of fermentation is 30 ℃, the time of fermentation is 29h, and the inoculum size is 2.5%), obtain the fermented Dendrobium candidum, then add the basic granules to stir, continue to ferment for 2h, and obtain the fermentation mixture;

[0034] (3) Mix 0.2g distiller's lees yeast culture and 20g fermentation m...

Embodiment 2

[0036] The preparation method of the grass carp fermented soft granule of the present embodiment may further comprise the steps:

[0037] (1) Mix 10g fish meal, 4g fermented soybean meal, 3g wheat bran, 5g canola meal, 3g fine bran, 2g corn bran, 1g premix, 0.05g zeolite powder, 1g calcium dihydrogen phosphate, 0.5g bentonite and 0.2 ml of bile acid, and spray condensation granulation at 40°C to obtain basic granules;

[0038] (2) saccharomycete, lactic acid bacteria, lactobacillus, mass concentration are 3% dendrobium pulp and mass concentration 5% fructose syrup are mixed and stirred, and fermented (moisture content control in the fermentation process is 29%, and the temperature of fermentation is 30 ℃, the time of fermentation is 29h, and the inoculum size is 4%), obtain the fermented Dendrobium candidum, then add the basic granules to stir, continue to ferment for 2h, and obtain the fermentation mixture;

[0039](3) Mix 0.2g distiller's lees yeast culture and 20g fermenta...

Embodiment 3

[0041] The preparation method of the grass carp fermented soft granule of the present embodiment may further comprise the steps:

[0042] (1) Mix 10g fish meal, 4g fermented soybean meal, 3g wheat bran, 5g canola meal, 3g fine bran, 2g corn bran, 1g premix, 0.05g zeolite powder, 1g calcium dihydrogen phosphate, 0.5g bentonite and 0.2 ml of bile acid, and spray condensation granulation at 40°C to obtain basic granules;

[0043] (2) Yeast, lactic acid bacteria, lactobacillus, mass concentration are 5% dendrobium pulp and mass concentration 5% fructose syrup are mixed and stirred, and fermented (moisture content control in the fermentation process is 29%, and the temperature of fermentation is 30 ℃, the time of fermentation is 29h, and the inoculum size is 2.5%), obtain the fermented Dendrobium candidum, then add the basic granules to stir, continue to ferment for 2h, and obtain the fermentation mixture;

[0044] (3) Mix 0.1g distiller's lees yeast culture with 20g fermentation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com