Preparation system and preparation method of battery pole piece

A technology for preparing systems and battery pole pieces, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problems of unenvironmental protection, inconsistent positive and negative surface densities of bipolar pole pieces, slow coating efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

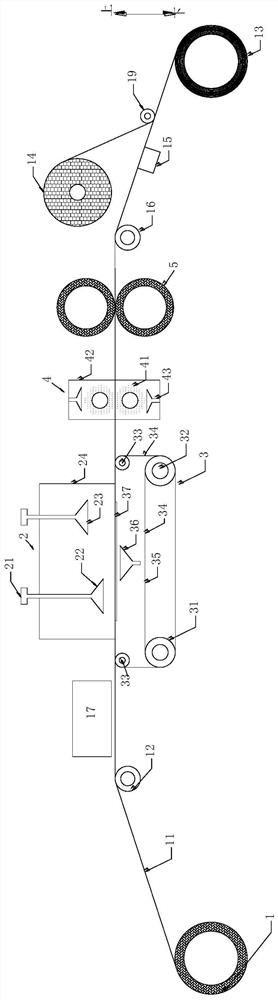

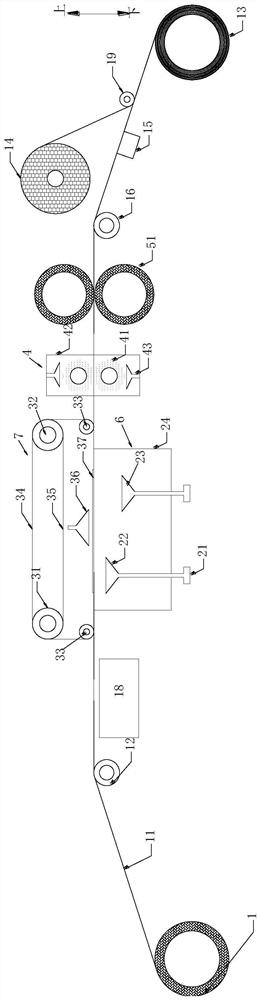

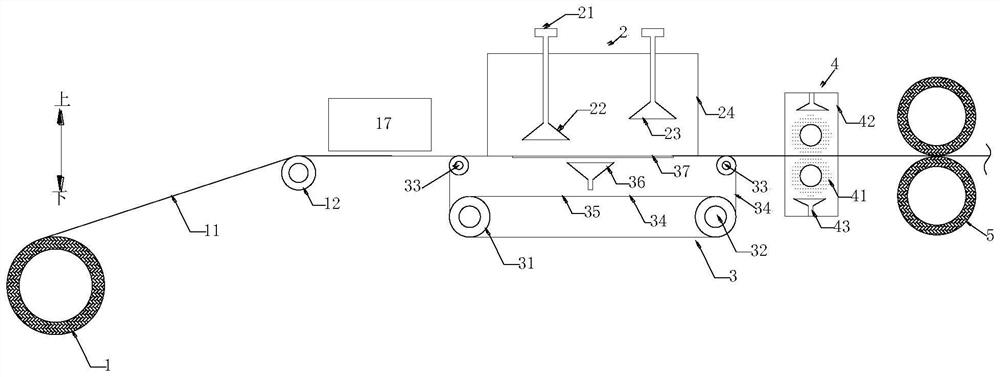

[0058] Such as figure 1 As shown, a battery pole piece preparation system of this embodiment includes a pole piece base material unwinding device 1, a pole piece base material winding device 13, an electrostatic spraying device, an isolation device and a rolling device, and the pole piece The substrate unwinding device 1 and the pole piece base material winding device 13 are arranged at intervals to be used for the winding and unwinding of the pole piece base material 11, and the electrostatic spraying device and the isolating device are arranged along a direction perpendicular to the winding or unwinding The direction is relatively arranged between the pole piece base material unwinding device 1 and the pole piece base material winding device 13, and there is a device for the pole piece base material 11 to pass between the electrostatic spraying device and the isolation device. gap, the rolling device is arranged downstream of the electrostatic spraying device in the moving d...

specific Embodiment approach 1

[0061] Embodiment one, the first isolating device 3 can be directly covered on one side of the pole piece base material 11 by using an isolation cover, and the isolation cover can be infinitely close to one side of the pole piece base material 11, so that effective isolation and protection can be realized. It will not affect the winding and unwinding movement of the pole piece base material 11 . A dust suction part can also be arranged in the isolation cover to effectively absorb the dust entering the isolation cover.

specific Embodiment approach 2

[0062] Specific implementation mode two, such as figure 1 As shown, the first isolation device 3 includes a transmission mechanism and a first isolation film 34, and the first isolation film 34 is attached to one side of the pole piece base material 11 and covers the other side of the pole piece base material 11. In the spray coating area, the conveying mechanism is connected with the first isolation film 34 and drives the first isolation film 34 to reciprocate along the moving direction of the pole piece base material 11 . The other side of the pole piece base material 11 corresponds to the spray coating area of the electrostatic spraying device. When the pole powder is sprayed, one side of the pole piece base material 11 is effectively attached to the first isolation film 34, and no dust will enter The gap can effectively isolate the protection, isolate the external dust, and avoid being polluted by the sprayed powder. And because the pole piece base material 11 moves con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com