Anti-seismic fabricated building steel structure

A steel structure and assembly technology, applied in the direction of building components, buildings, protective buildings/shelters, etc., can solve the problems of cumbersome assembly work, high-strength buffer protection work, rigid connection fracture, etc., to increase the safety and security of use Stability, improvement of anti-seismic performance, effect of increasing anti-seismic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the implementation of the present invention in detail in conjunction with the accompanying drawings.

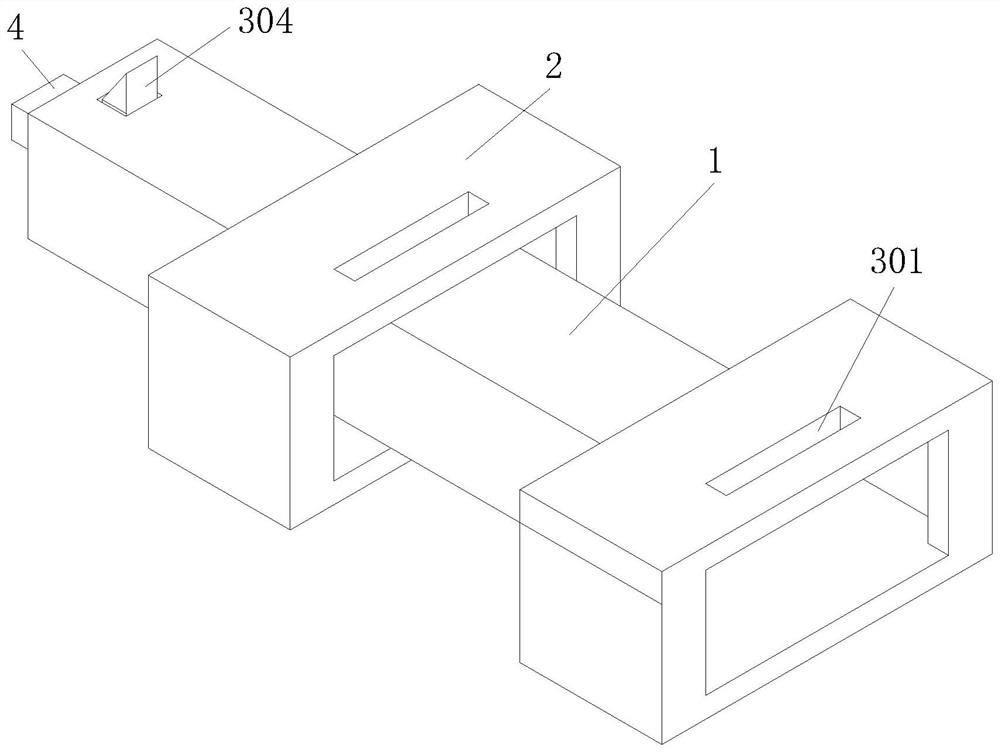

[0038] Such as Figure 1-9 As shown, an anti-seismic assembled building steel structure includes a steel plate body 1, one end of the steel plate body 1 is welded and fixed with a mounting frame 2, the other end of the steel plate body 1 is welded and fixed with a positioning block 4, and the steel plate body 1 is installed with an assembly assembly 3. There is a positioning groove 5 in the installation frame 2, and the positioning block 4 is snapped and connected in the positioning groove 5. The first buffer and shock absorbing assembly 6 and the second buffer and shock absorbing assembly 9 are installed in the installation frame 2, and the positioning block 4 A storage tank 10 is provided, and a red paint 11 is arranged in the storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com