Shell structure of moisture removal device of clothes dryer, moisture removal device and clothes dryer

A technology for clothes dryers and shells, which is applied in the field of clothes dryers, and can solve the problems such as the environmental humidity and temperature of clothes dryers are greatly affected, and achieve the effect of simplifying the connection of pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

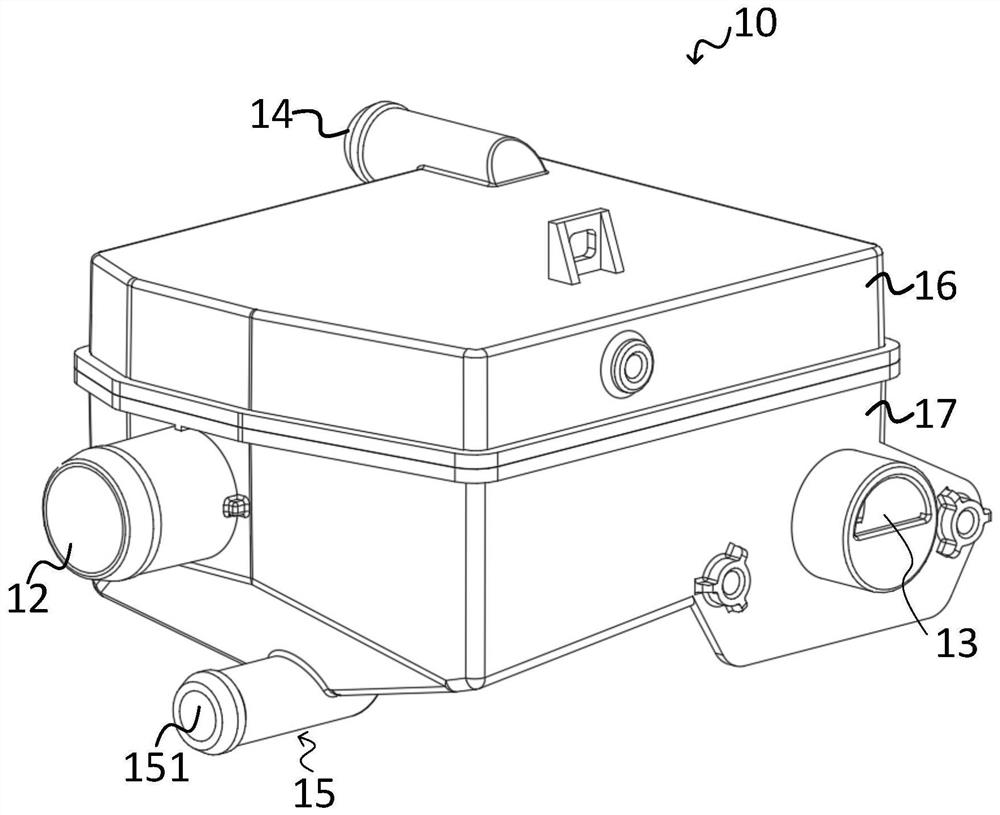

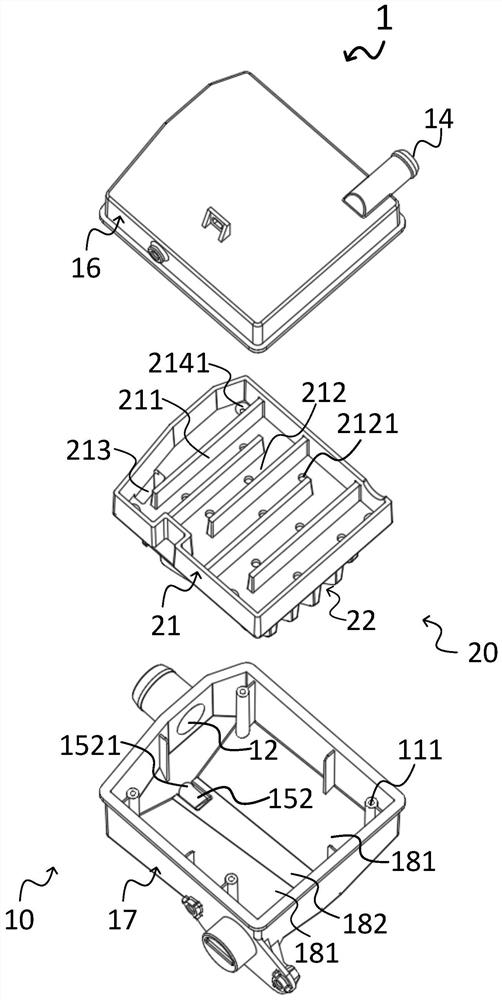

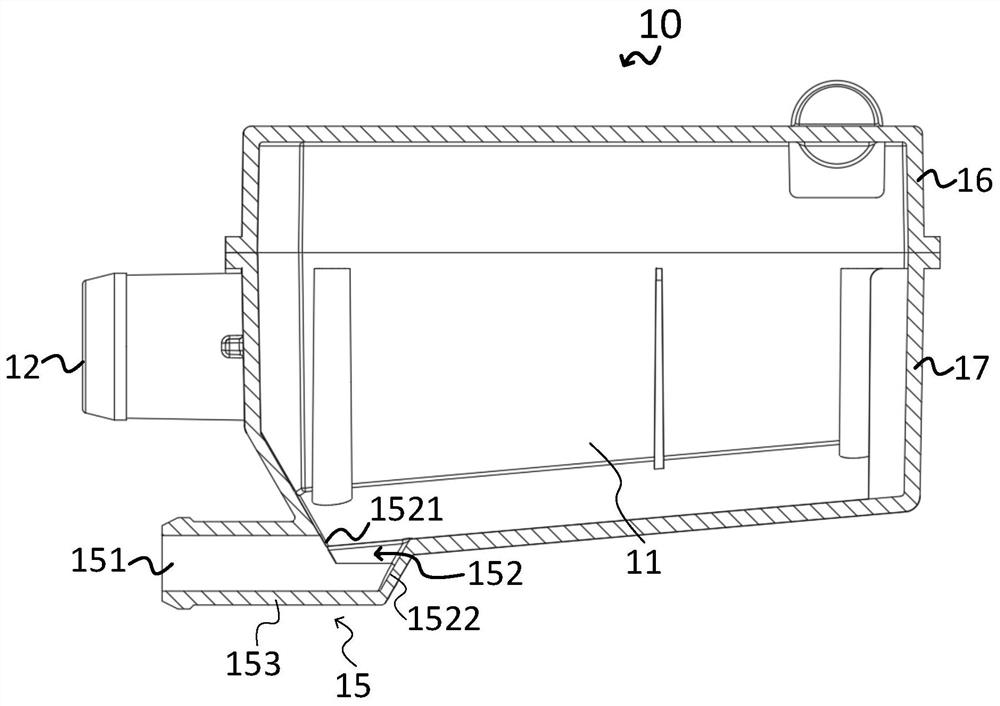

[0051] The present invention provides a shell structure of a dehumidification device for a clothes dryer, which includes an outer surface shell 10 for forming a dehumidification device body 1 disposed in the main body of the clothes dryer; Figure 1 to Figure 5 As shown, the housing 10 includes:

[0052] The cavity 11 is used to accommodate the heat exchange element 20; the cavity 11 is also used to form a temporary storage space for the hot and humid air. After the hot and humid air enters the cavity 11, the flow speed of the hot and humid air is reduced due to the constraint of the contour of the cavity 11 , so that the hot and humid air is temporarily gathered in the cavity 11 to contact the heat exchange element 20 in the cavity 11;

[0053] The air inlet 12 is used to pass into the cavity 11 the hot and humid air generated by the drying drum of the dryer body;

[0054] The air outlet 13 is used to discharge the hot and humid air to the outside of the dryer body after bei...

Embodiment 2

[0068] The invention provides a dehumidification device, such as figure 1 , image 3 , Figure 4 , Figure 5 As shown, it includes a dehumidification device body 1 arranged in the clothes dryer body, and the dehumidification device body 1 includes:

[0069] The casing 10 as described above; the casing 10 is provided with a cavity 11 for accommodating the heat exchange element 20 , an air outlet 13 , and a drainage pipe 15 ; the heat exchange element 20 is arranged in the cavity 11 of the casing 10 ;

[0070]The heat exchange element 20 is used to cool the hot and humid air in the cavity 11; the heat exchange element 20 is arranged in the cavity 11; the hot and humid air in the drying drum of the clothes dryer body enters the cavity 11, and the heat exchange element 20 absorbs The heat of hot and humid air is condensed during the cooling process of hot and humid air to form condensed water for dehumidification. The cooled and dehumidified air is discharged to the outside of ...

Embodiment 3

[0107] The present invention provides a clothes dryer, which includes a clothes dryer body for performing drying, and the clothes dryer body includes the moisture draining device body 1 of a moisture draining device for a clothes dryer as described above. The main body of the clothes dryer includes a cabinet and a drying cylinder; the drying cylinder and the dehumidification device body 1 are all arranged in the cabinet, and the air outlet 13 of the dehumidification device body 1 is in one-way communication with the external environment of the cabinet, so as to seal the cavity The hot and humid air in 11 is discharged out of the casing after being cooled and dehumidified. When the dryer body executes the drying program, the hot and humid air in the drying cylinder is passed into the cavity 11 from the air inlet 12, and after being cooled by the cooling part 21, the moisture in the hot and humid air is condensed and removed, and then discharged from the air outlet 13 Outside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com