Polymer-metal-MOF-ionic liquid composite alkaline anion exchange membrane and preparation method thereof

An alkaline anion, ionic liquid technology, used in fuel cells, electrochemical generators, electrical components, etc., can solve problems such as performance degradation and chemical stability degradation, and achieve the effect of improving service life and breaking through performance degradation over time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 2,6-bis(4-1H-pyrazolyl)-1,3,5,7-pyromellitic acid diimide (H 2 MPDI) (0.0191 g, 0.05 mmol) and isophthalic acid (0.025 g, 0.12 mmol) were dissolved in 2 mL of DMF, and the solution became clear after stirring for 5 minutes.

[0041] Cu(NO 3 ) 2 ·3H 2 O (0.0242 g, 0.1 mmol) was dissolved in 2 mL of DMF and the solution became clear after stirring for 5 min.

[0042] After mixing the above two mixed solutions evenly, continue to add 1mL methanol and 0.1mL 1mol / L hydrochloric acid solution, stir evenly and react at 150°C for 3 days to obtain red crystal Cu-MOF.

[0043] The ionic liquid 1-methyl-3-vinylimidazole hydroxide was dissolved in ethanol to form a 1 mol / L ionic liquid solution.

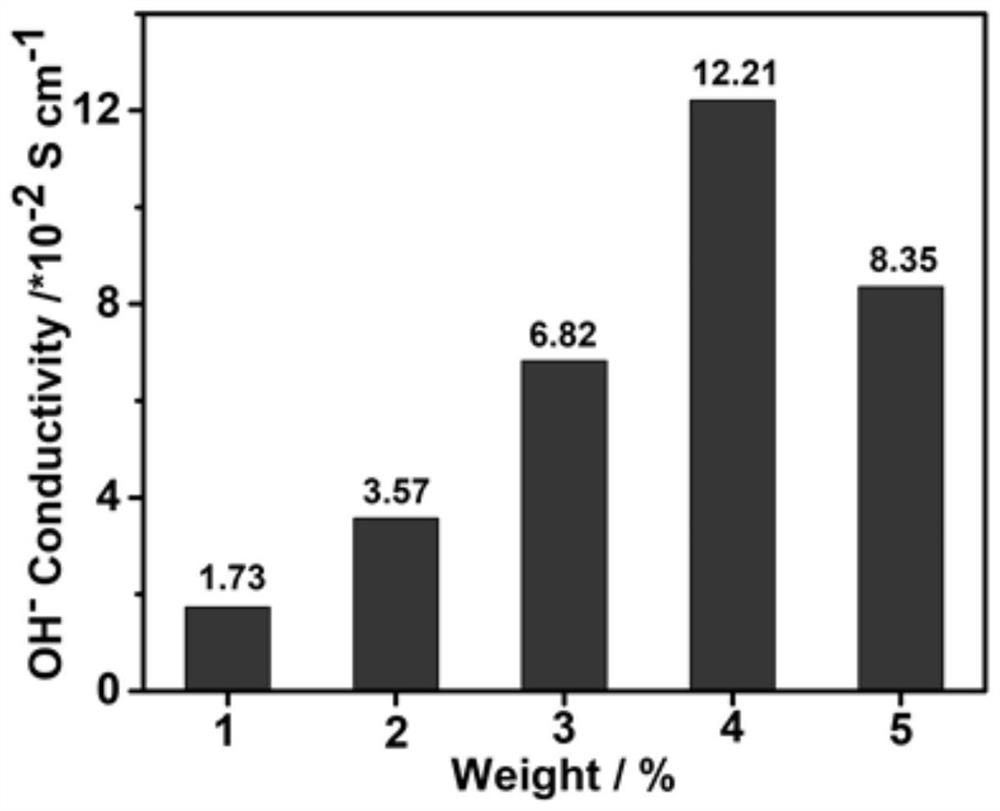

[0044] The red crystals were dispersed in 10 mL of the above ionic liquid solution, configured as an ionic liquid with a mass percentage of 4%, and centrifuged at 10,000 rpm for 10 minutes to obtain Cu-MOF@ionic liquid.

[0045] After dissolving 2g of PVA in distilled water at 90°C, ...

Embodiment 2

[0047] 2,6-bis(4-1H-pyrazolyl)-1,3,5,7-pyromellitic acid diimide (H 2 MPDI) and isophthalic acid are dissolved in the DMF of 2mL, and its ratio is as shown in Table 1. The solution became clear after stirring for 5 minutes.

[0048] Cu(NO 3 ) 2 ·3H 2 O (0.0242 g, 0.1 mmol) was dissolved in 2 mL of DMF and the solution became clear after stirring for 5 min.

[0049] After mixing the above two mixed solutions evenly, continue to add 1mL methanol and 0.1mL 1mol / L hydrochloric acid solution, stir evenly and react at 150°C for 3 days to obtain red crystal Cu-MOF.

[0050] The ionic liquid 1-methyl-3-vinylimidazole hydroxide was dissolved in ethanol to form a 1 mol / L ionic liquid solution.

[0051] The red crystals were dispersed in 10 mL of the above ionic liquid solution, configured as an ionic liquid with a mass percentage of 4%, and centrifuged at 10,000 rpm for 10 minutes to obtain Cu-MOF@ionic liquid.

[0052] After dissolving 2g of PVA in distilled water at 90°C, add Cu...

Embodiment 3

[0057] 2,6-bis(4-1H-pyrazolyl)-1,3,5,7-pyromellitic acid diimide (H 2 MPDI) (0.0191 g, 0.05 mmol) and isophthalic acid (0.025 g, 0.12 mmol) were dissolved in 2 mL of DMF, and the solution became clear after stirring for 5 minutes.

[0058] Taking different masses of Cu(NO 3 ) 2 ·3H 2 O was dissolved in 2mL of DMF, and its ratio was shown in Table 2. The solution became clear after stirring for 5 minutes.

[0059] After mixing the above two mixed solutions evenly, continue to add 1mL methanol and 0.1mL 1mol / L hydrochloric acid solution, stir evenly and react at 150°C for 3 days to obtain red crystal Cu-MOF.

[0060] The ionic liquid 1-methyl-3-vinylimidazole hydroxide was dissolved in ethanol to form a 1 mol / L ionic liquid solution.

[0061] The red crystals were dispersed in 10 mL of the above ionic liquid solution, configured as an ionic liquid with a mass percentage of 4%, and centrifuged at 10,000 rpm for 10 minutes to obtain Cu-MOF@ionic liquid.

[0062] After dissol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com