Packaging box cutting device

A cutting device and packaging box technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve the problems of packaging box output reduction, cutting deviation, waste, etc., to reduce transportation work, improve cutting accuracy, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

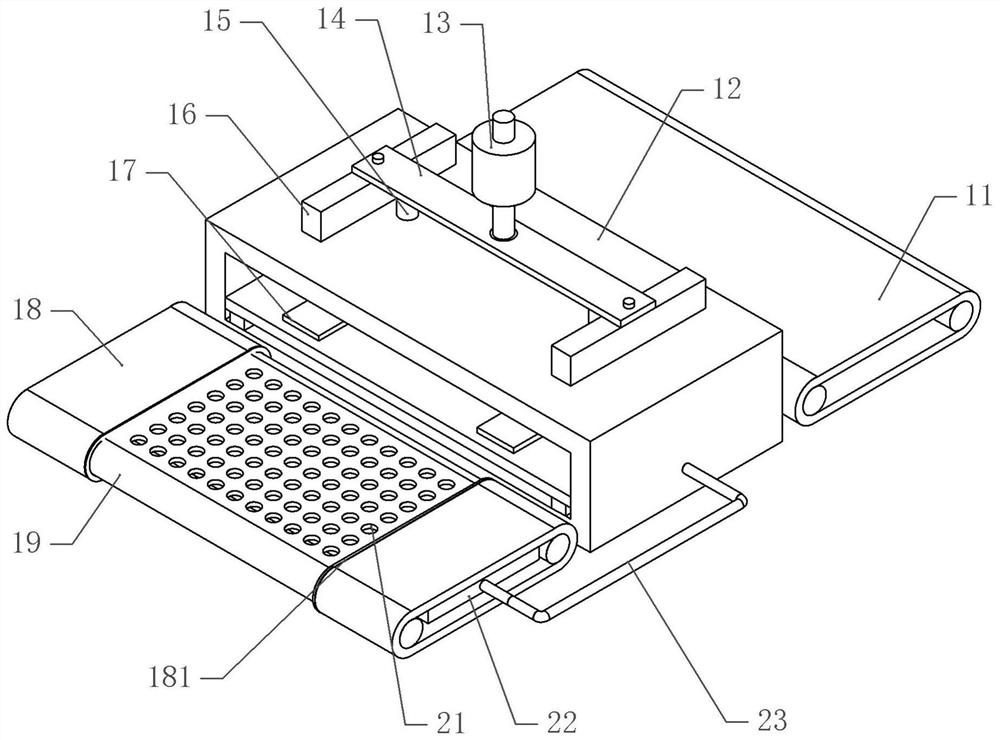

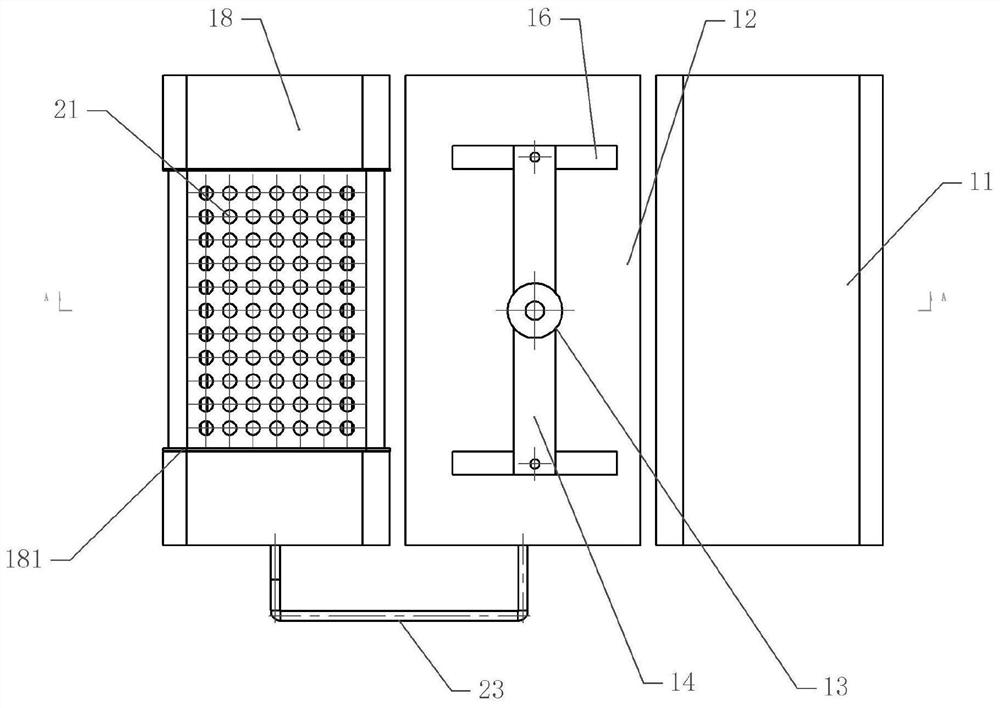

[0035] Basic as attached figure 1 , attached figure 2 , attached image 3 And attached Figure 4 As shown, a packing box cutting device includes a frame, a feed conveyor belt 11 is installed on one side of the frame, and a discharge conveyor belt is installed on the other side of the frame, between the feed conveyor belt 11 and the discharge conveyor belt A cutting mechanism is installed.

[0036] In the present embodiment, the cutting mechanism includes a cutting box 12 fixed on the frame by bolts, openings on both sides of the cutting box 12, and a driving part is fixedly connected to the frame, and the driving part is a hydraulic cylinder 13, and the output shaft bolt of the hydraulic cylinder 13 A cutting board 14 is fixed, and both sides of the cutting board 14 are bolted with cutting knives 16. The cutting knives 16 run through the cutting box 12 and the cutting knives 16 and the cutting box 12 are vertically slidingly fitted.

[0037] The cutting knife 16 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com