Space-time frequency shaping femtosecond laser hemispherical resonator gyroscope base electrode etching method

A hemispherical resonant gyro, femtosecond laser technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of increased edge burrs, increased residual thermal stress, excessive substrate ablation, etc., to achieve low substrate damage , Improve edge quality, homogenize the effect of substrate ablation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to better understand the method of the present invention, the technical solution of the present invention will be further described in detail below in conjunction with specific examples.

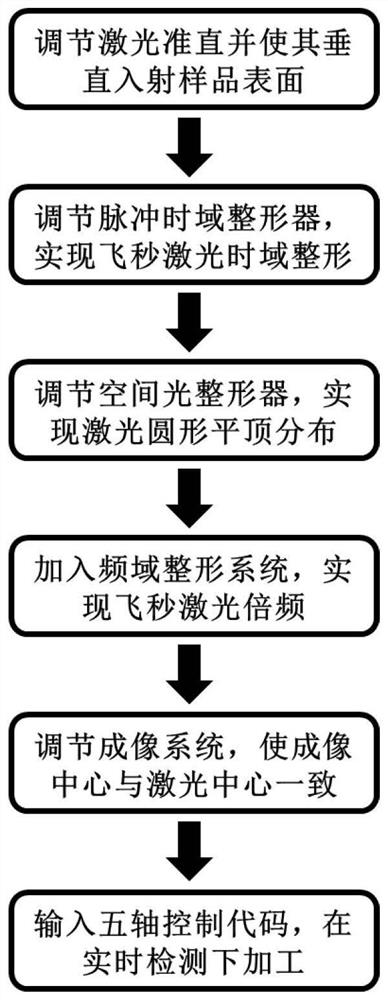

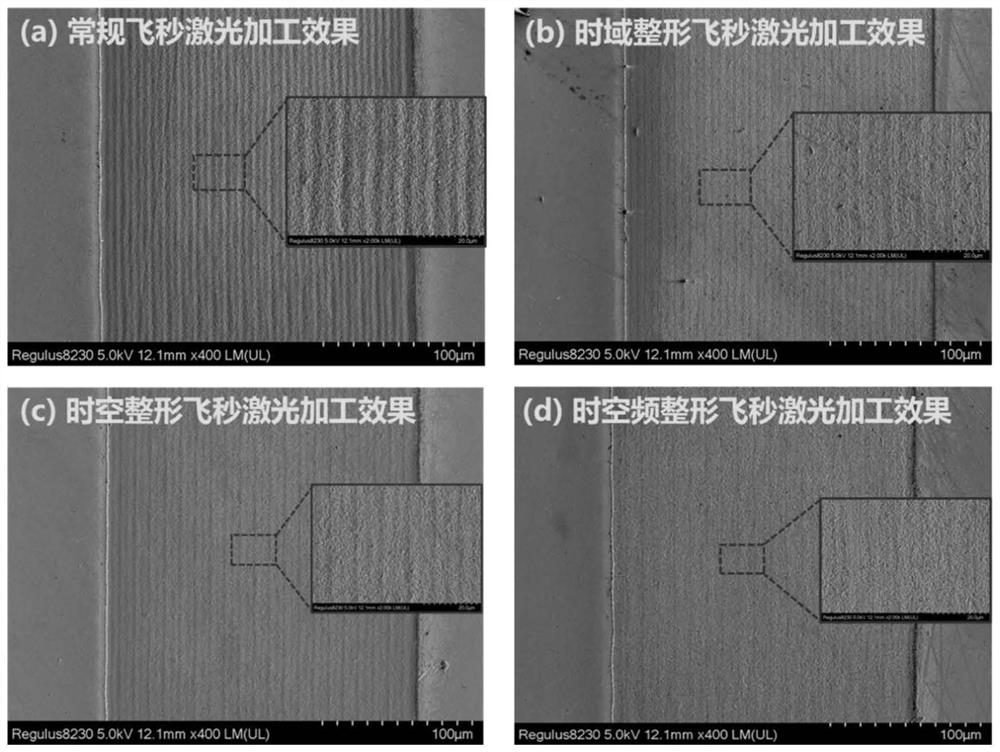

[0041] Such as figure 1 As shown, the femtosecond laser hemispherical resonator gyro pedestal electrode profiling method based on time-space-frequency shaping disclosed in this embodiment, the original femtosecond laser pulse is shaped by time-domain shaping, space shaping and frequency-domain shaping to form a time-space-frequency collaborative shaping pulse, After being focused by the objective lens, it is irradiated on the surface of the base electrode of the hemispherical resonant gyroscope, and the imaging subsystem and high-precision five-axis translation stage are used to realize the on-line monitoring of patterning and processing.

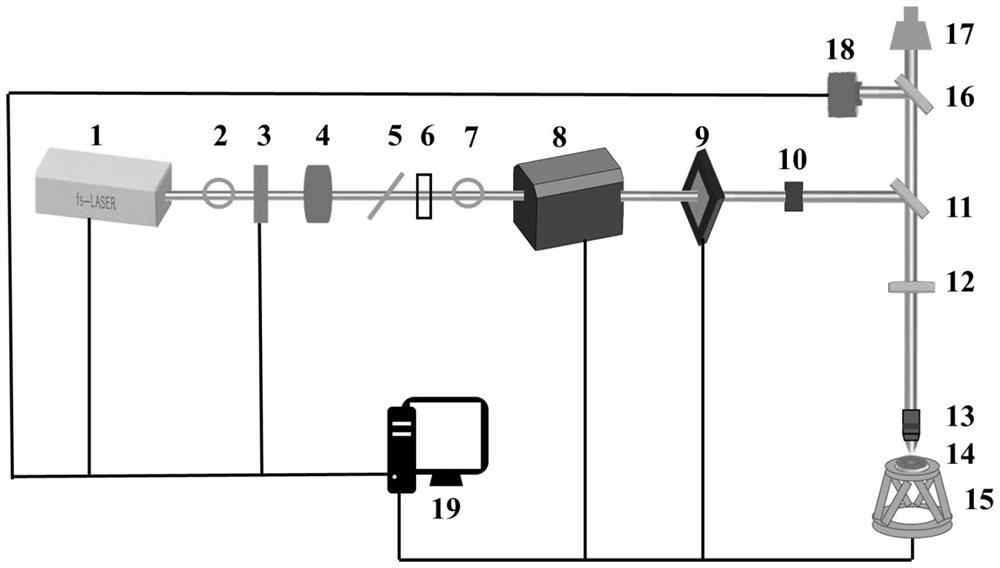

[0042] Such as figure 2 As shown, a hemispherical resonator gyroscope base electrode profiling processing system based on time-space fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com