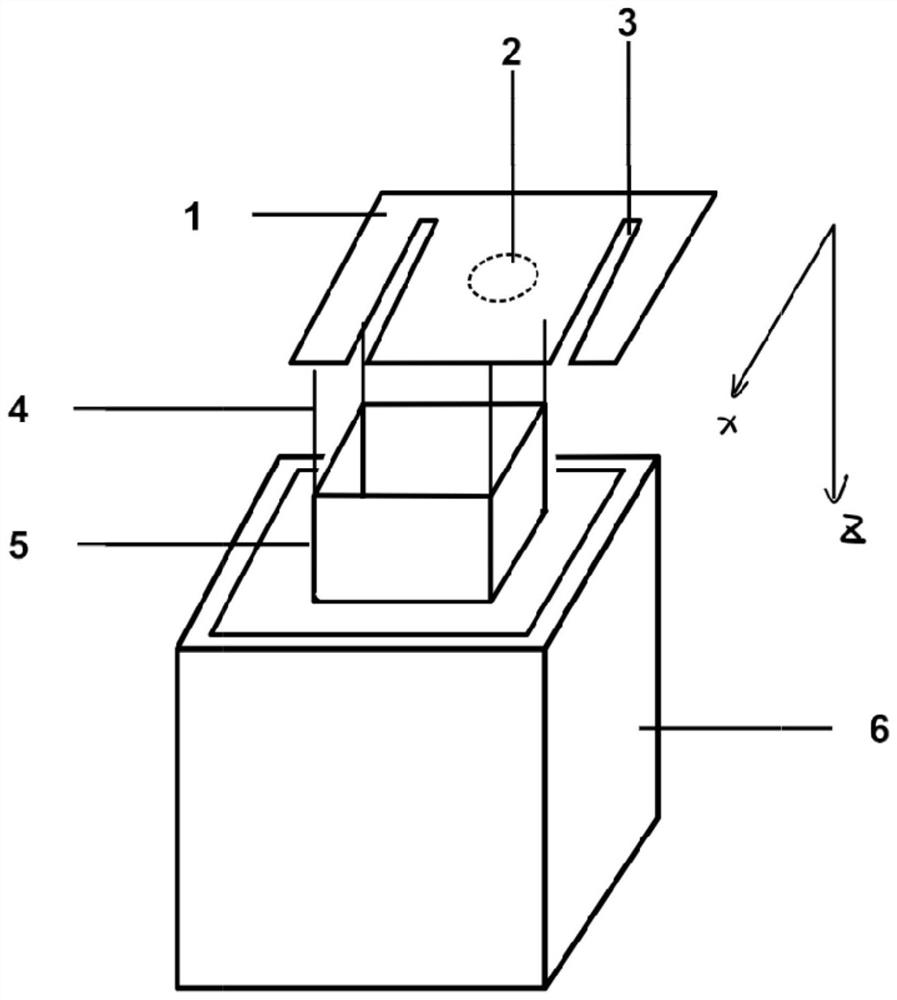

Sound reflection top cover structure for ultrasonic cleaning device

A technology of ultrasonic cleaning and sound reflection, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as sound energy dissipation, increase sound field intensity, strengthen ultrasonic diffuse reflection, uniformity Effect of cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

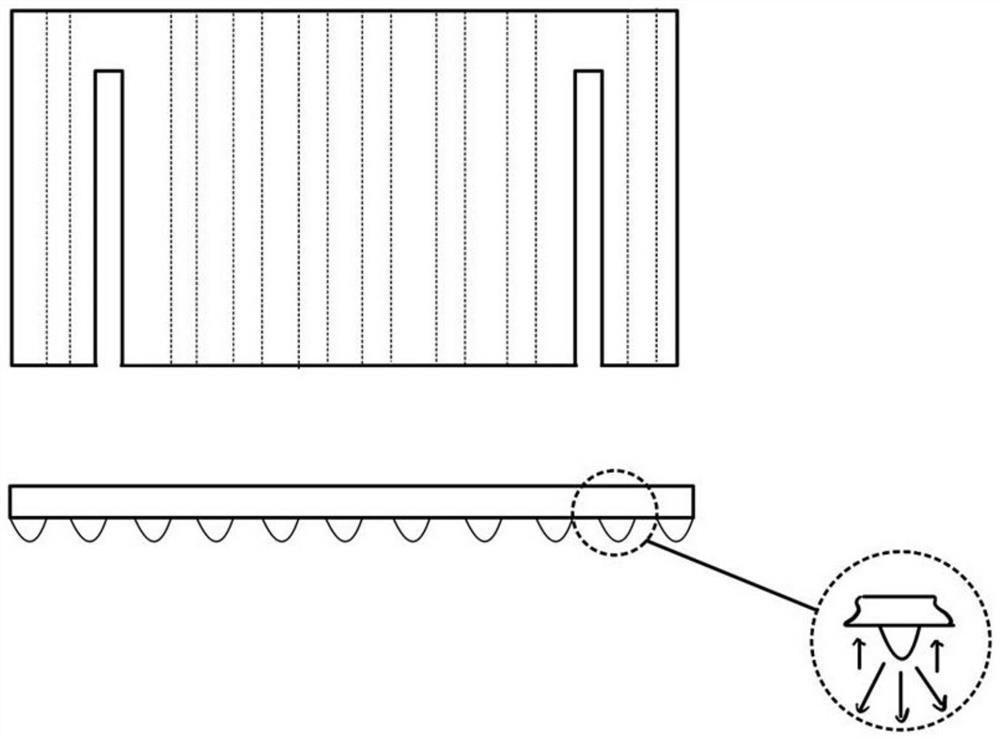

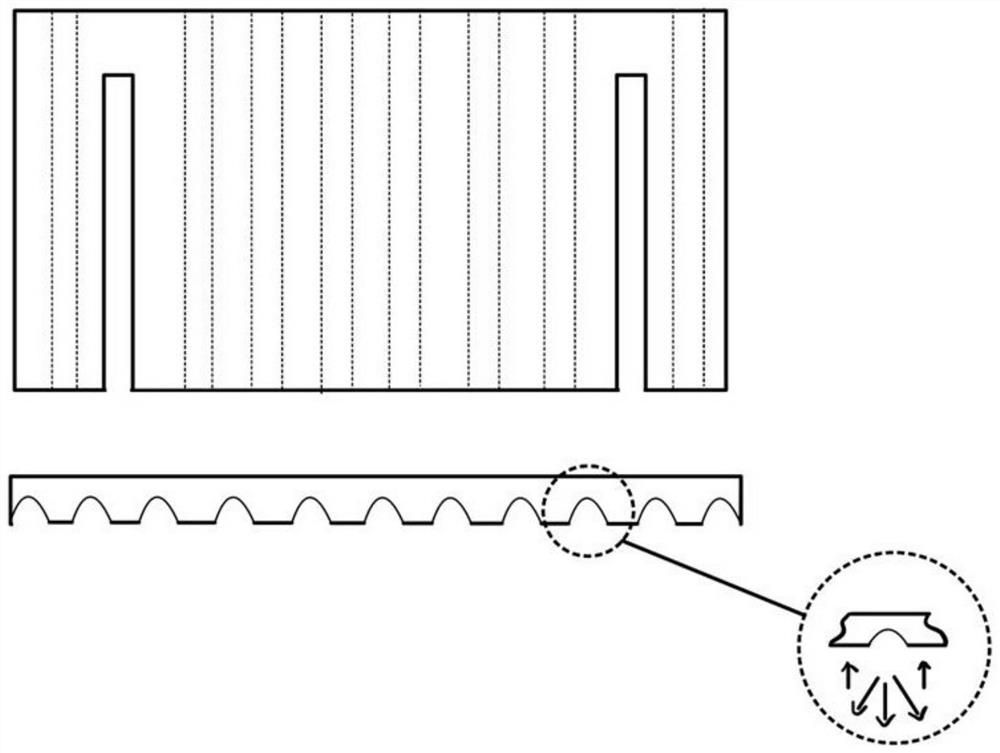

Embodiment example 1

[0034] The experimental operating environment is 201°C, and the working frequency of the ultrasonic transducer is f=65.0KHz. The objects to be cleaned are metal parts with stubborn dirt such as organic oil on the surface of the parts. Choose an ultrasonic reflective cover made of metal, and choose a concave-tooth acoustic focusing structure on the lower surface of the reflective cover, and apply ultrasonic waves for ultrasonic cleaning. Compared with the control group without ultrasonic reflection cover installed at the same cleaning time and power, the cleaning efficiency increased by 37.3%.

[0035] Due to the application of the above technical solution, the present invention has the following advantages compared with the prior art: on the basis of not changing the structure of the existing ultrasonic cleaning device, by adding a top cover, the surface tension wave and the atomization effect can be effectively reduced. Acoustic energy dissipation, simple structure, easy ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com