A Structural Design Method for Axisymmetric Nozzles in Hypersonic Wind Tunnels

An axisymmetric nozzle, hypersonic technology, applied in design optimization/simulation, computer-aided design, testing of machine/structural components, etc., can solve the problem of high cost, long processing cycle, and difficulty in processing hypersonic wind tunnel nozzles Large and other problems, to achieve the effect of reducing weight, reducing processing difficulty, and good velocity field index performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

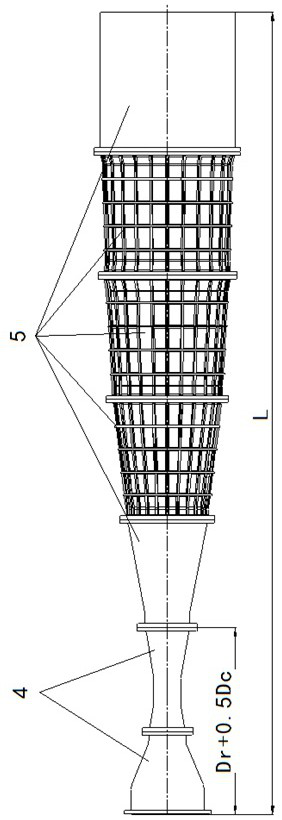

[0067] The structural design method for the axisymmetric nozzle of the hypersonic wind tunnel in this embodiment is based on the principle of aerodynamic design of the inner profile of the nozzle, reasonably divides the segmented position of the nozzle structure, and minimizes the segmentation of key parts.

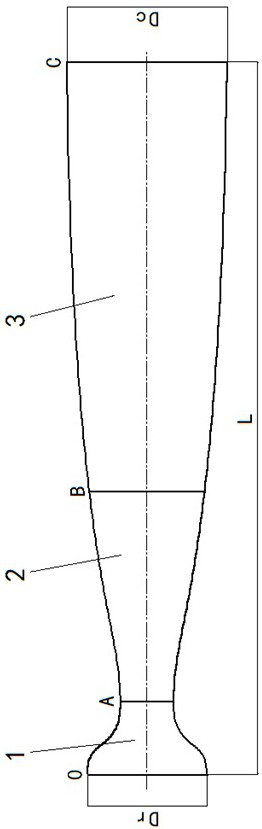

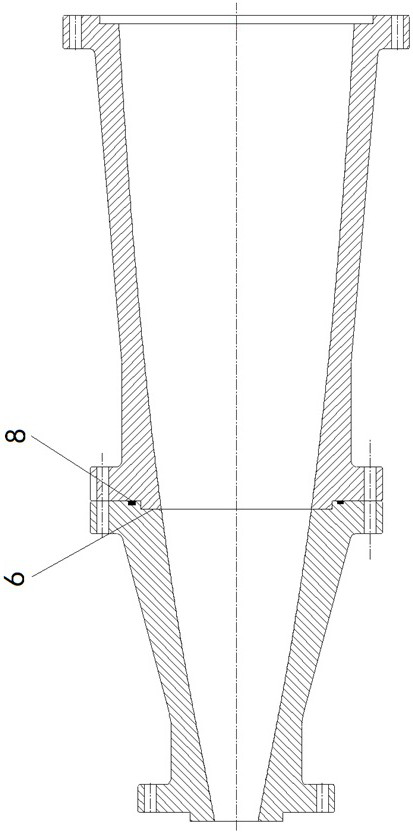

[0068] Such as figure 1 As shown, the aerodynamic design of the nozzle is generally divided into three parts: the subsonic contraction section 1, the initial expansion section 2, and the parallel flow section 3. The location of the subsonic constriction section 1 is the OA section, that is, the nozzle inlet O to the nozzle throat A with the smallest diameter. In order to avoid separation, the airflow reaches the speed of sound at the outlet, and at the same time, the pulsation degree of the airflow is improved, so that the airflow at the throat A of the nozzle is uniform and stable. The position area of the initial expansion section 2 is the AB section, and its functi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com