Self-source etching preparation method and application of nickel-doped iron oxyhydroxide self-supporting electrode material

An iron oxyhydroxide, self-supporting electrode technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of reducing catalyst conductivity, reducing the number of effective active sites, reducing catalytic activity, etc. Conducive to large-scale preparation and application, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

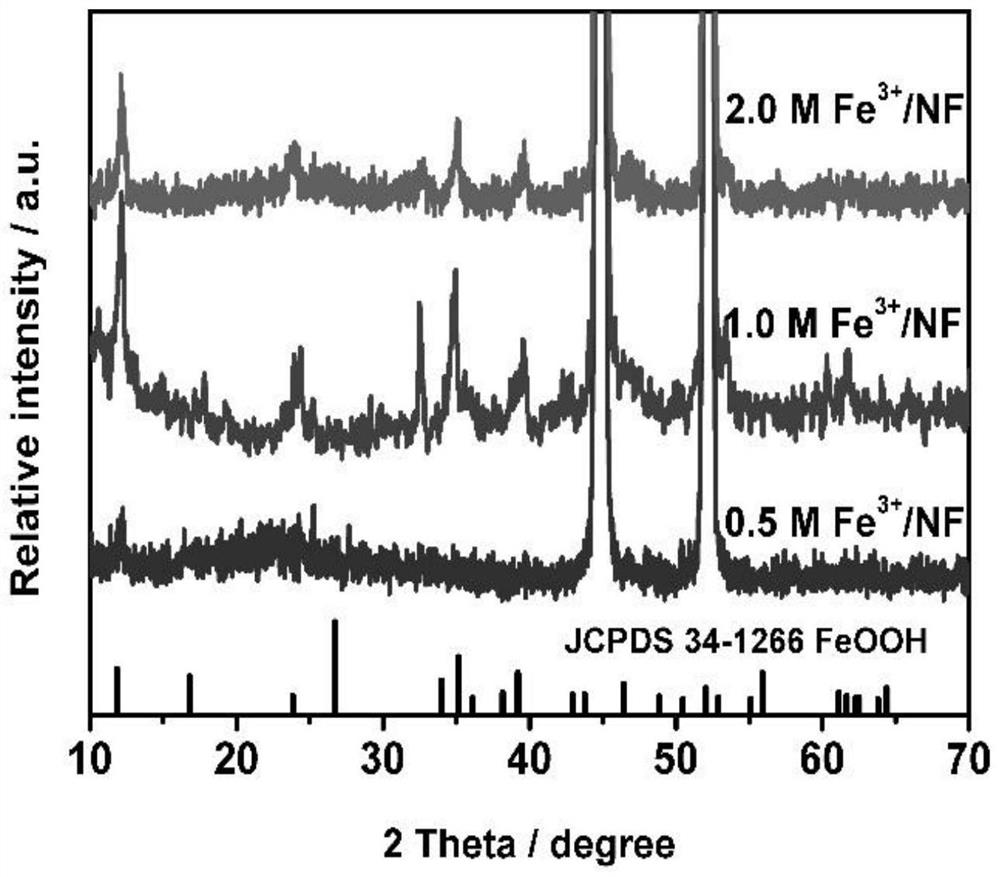

[0031] Add 1.0 mmol of ferric chloride hexahydrate into 40 mL of deionized water and stir for 10 min. Then, the cut and cleaned 1×3cm foamed nickel was placed at the bottom of the reactor, and the evenly stirred solution was poured into the reactor so that the foamed nickel substrate could be completely immersed in the solution, and then sealed. Place in an oven, and undergo low-temperature hydrothermal treatment at 60°C for 12 hours; open the hot water kettle that has been completely cooled to room temperature, add 0.2g of urea, and perform ultrasonic dispersion treatment to dissolve the urea and disperse it evenly, and then seal it; In an oven, undergo a secondary hydrothermal treatment at 120°C for 12 hours; open the hot water kettle after it is completely cooled to room temperature, take out the nickel foam material, and finally obtain a nickel-doped iron oxyhydroxide self-supporting electrode material after washing and drying. (1.0M Fe 3+ / NF).

Embodiment 2

[0033] Add 0.5 mmol of ferric chloride hexahydrate into 40 mL of deionized water and stir for 10 min. Then, the cut and cleaned 1×3cm foamed nickel was placed at the bottom of the reactor, and the evenly stirred solution was poured into the reactor so that the foamed nickel substrate could be completely immersed in the solution, and then sealed. Place in an oven, and undergo low-temperature hydrothermal treatment at 60°C for 12 hours; open the hot water kettle that has been completely cooled to room temperature, add 0.2g of urea, and perform ultrasonic dispersion treatment to dissolve the urea and disperse it evenly, and then seal it; In an oven, undergo a secondary hydrothermal treatment at 120°C for 12 hours; open the hot water kettle after it is completely cooled to room temperature, take out the nickel foam material, and finally obtain a nickel-doped iron oxyhydroxide self-supporting electrode material after washing and drying. (0.5M Fe 3+ / NF).

Embodiment 3

[0035]Add 2 mmol of ferric chloride hexahydrate into 40 mL of deionized water and stir for 10 min. Then, the cut and cleaned 1×3cm foamed nickel was placed at the bottom of the reactor, and the evenly stirred solution was poured into the reactor so that the foamed nickel substrate could be completely immersed in the solution, and then sealed. Place in an oven, and undergo low-temperature hydrothermal treatment at 60°C for 12 hours; open the hot water kettle that has been completely cooled to room temperature, add 0.2g of urea, and perform ultrasonic dispersion treatment to dissolve the urea and disperse it evenly, and then seal it; In an oven, undergo a secondary hydrothermal treatment at 120°C for 12 hours; open the hot water kettle after it is completely cooled to room temperature, take out the nickel foam material, and finally obtain a nickel-doped iron oxyhydroxide self-supporting electrode material after washing and drying. (2.0M Fe 3+ / NF).

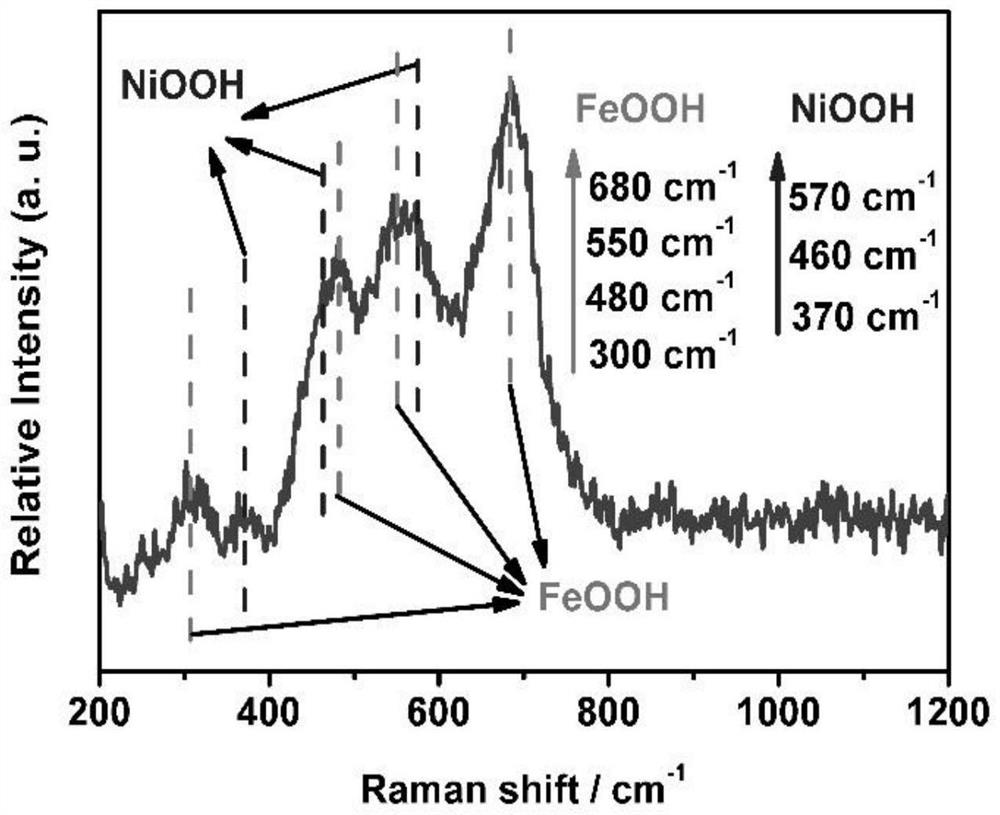

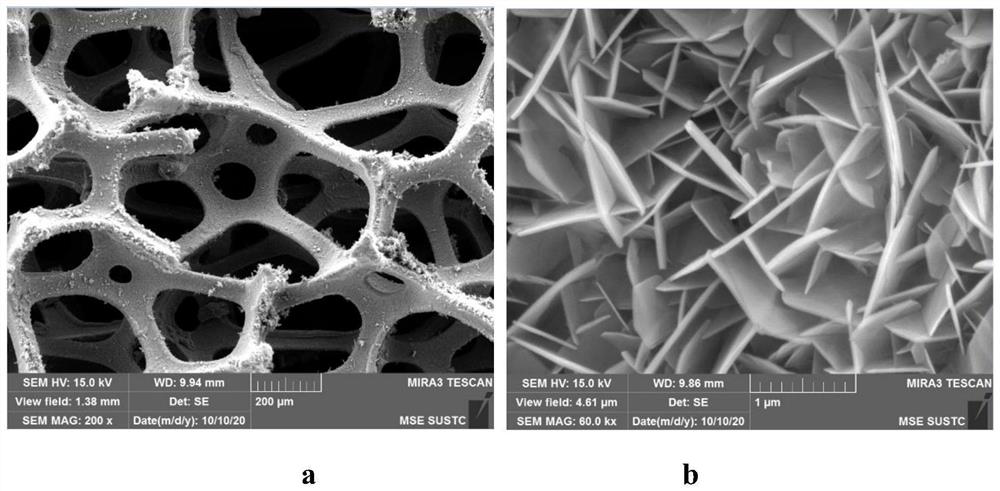

[0036] The structural test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com