Process for preparing clay firebrick by flotation tailing of bauxite

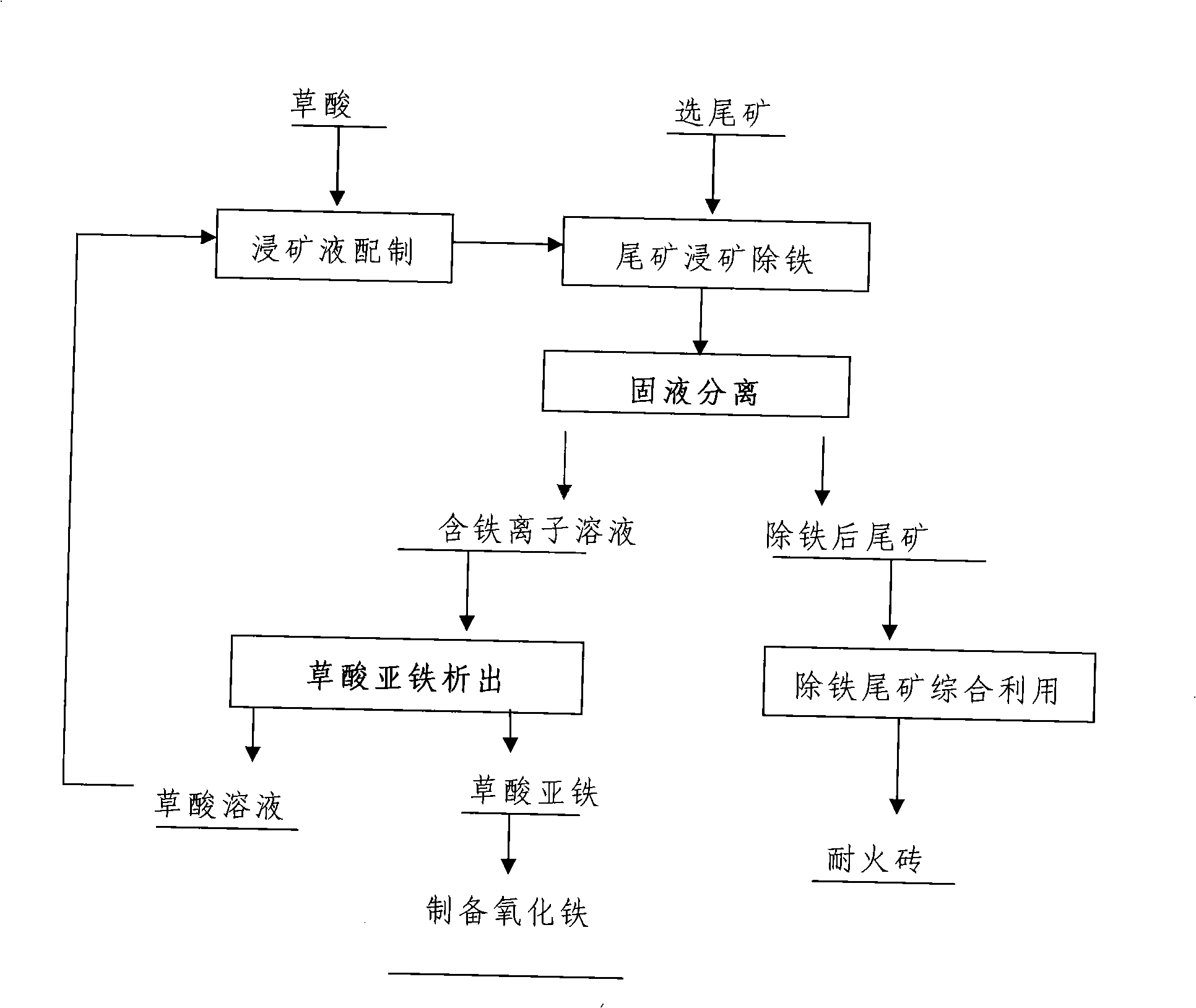

A technology for flotation tailings and bauxite, which is applied in the field of preparing clay refractory bricks from bauxite flotation tailings, can solve the problems of difficult engineering, difficult iron recovery, environmental pollution, etc., and achieves environmentally friendly, good Economic benefits and mild treatment conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

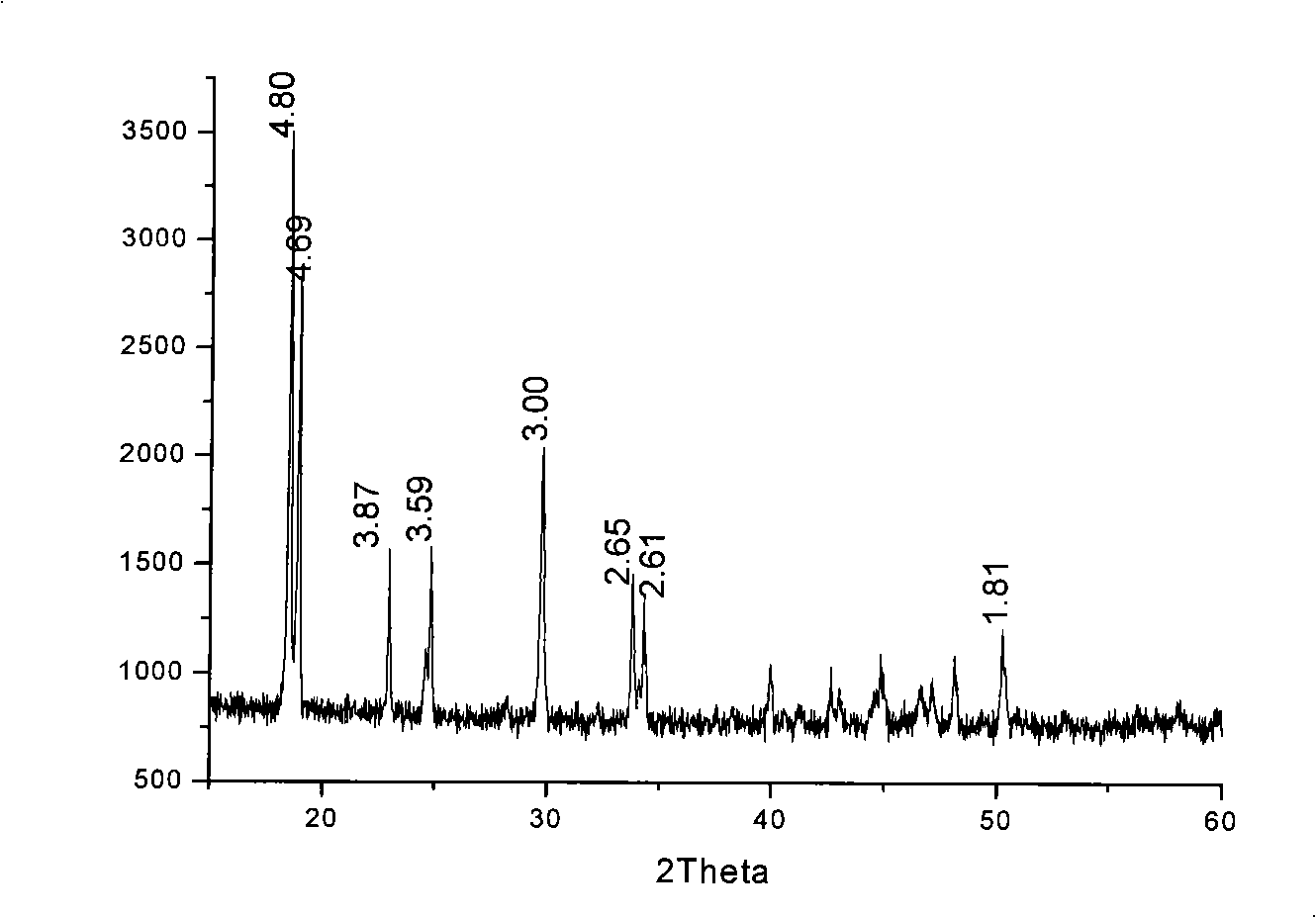

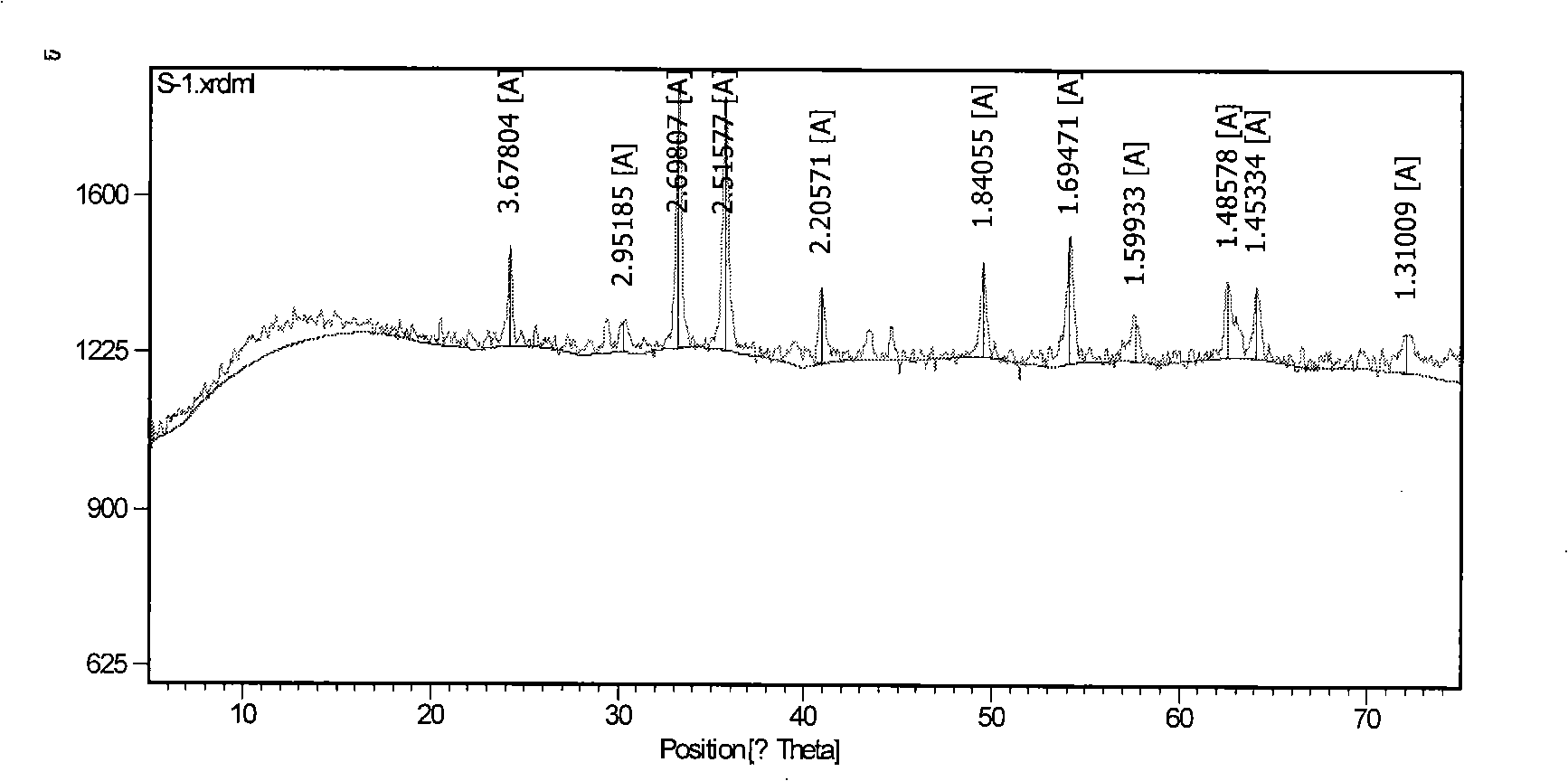

[0025] (1) Oxalic acid method to remove iron minerals in beneficiation tailings

[0026] Adding solid oxalic acid to the tailings slurry, adding water to make the concentration of oxalic acid 10%, stirring and leaching at 85° C. for 0.5 h; filtering to obtain iron-removing tailings and filtrate. The comparison of element content before and after tailings leaching is shown in Table 1.

[0027] Table 1 Comparison of chemical element content (%) before and after tailings leaching

[0028] Al 2 o 3

SiO 2

Fe 2 o 3

TiO 2

K 2 o

Na 2 o

MgO

CaO

Before leaching

43.278

28.895

10.33

3.130

4.221

0.234

0.389

0.159

After leaching

46.263

31.265

1.44

3.521

4.607

0.244

0.340

0.040

[0029] (2) Photocatalytic preparation of ferrous oxalate and recovery of oxalic acid

[0030] The filtrate obtained in step 1 is left standing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com