Rapid switching system and method for production of acid pickling flat coil and black flat coil

A fast switching, black flat coil technology, applied in the field of steel rolling, can solve the problems of a lot of labor and time to wash the acid tank, the wear of the squeeze roller, and the high energy consumption, so as to reduce the time and energy consumption of acid discharge and acid addition, and reduce the consumption of acid. The effect of small fog emission and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

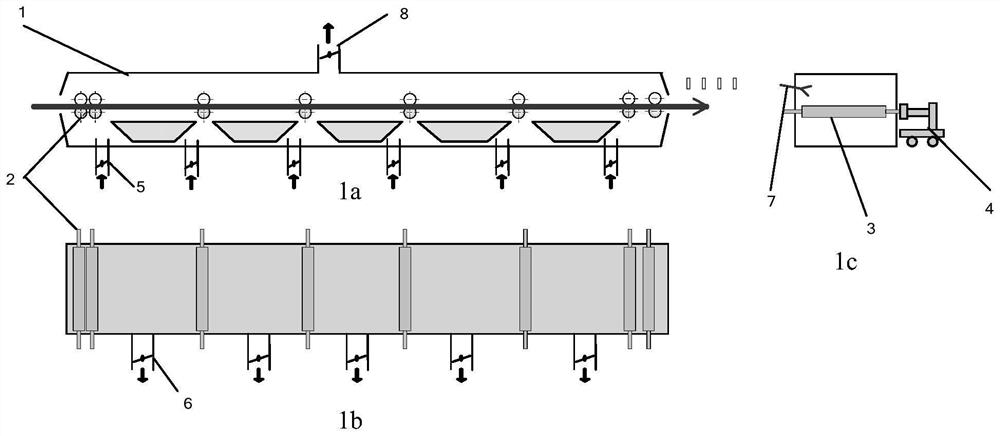

[0040] A quick switching method for the production of pickling level rolls and black flat rolls, through the switching between the squeezing roll 2 in the pickling section and the special roll 3 for black flat rolls, and the switching of the valves of the matching system of the acid tank, the pickling leveling is realized Quick switchover of roll and black flat roll production process, including the following steps:

[0041] Mode 1: switch from pickling flat roll to black flat roll production: switch from pickling flat roll production to black flat roll: close the acid circulation system and acid supply switch valve 5, open the acid discharge switch valve 6, and wait for the acid liquid to be completely discharged After emptying, open the quick flush nozzle 7, and after flushing the residual acid solution, close the acid discharge switch valve 6, the quick rinse nozzle 7, and the acid mist air duct switch valve 8. Simultaneously, the squeeze roller 2 is replaced with a special...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com