Composite heat-conducting PCB (printed circuit board)

A PCB circuit board, PCB board technology, applied in the direction of circuits, semiconductor devices, printed circuit components, etc., can solve the problems of reducing the service life of the chip, unable to quickly dissipate heat, and high operating temperature of the chip, so as to improve the heat dissipation capacity and avoid chip The effect of high temperature and increased heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

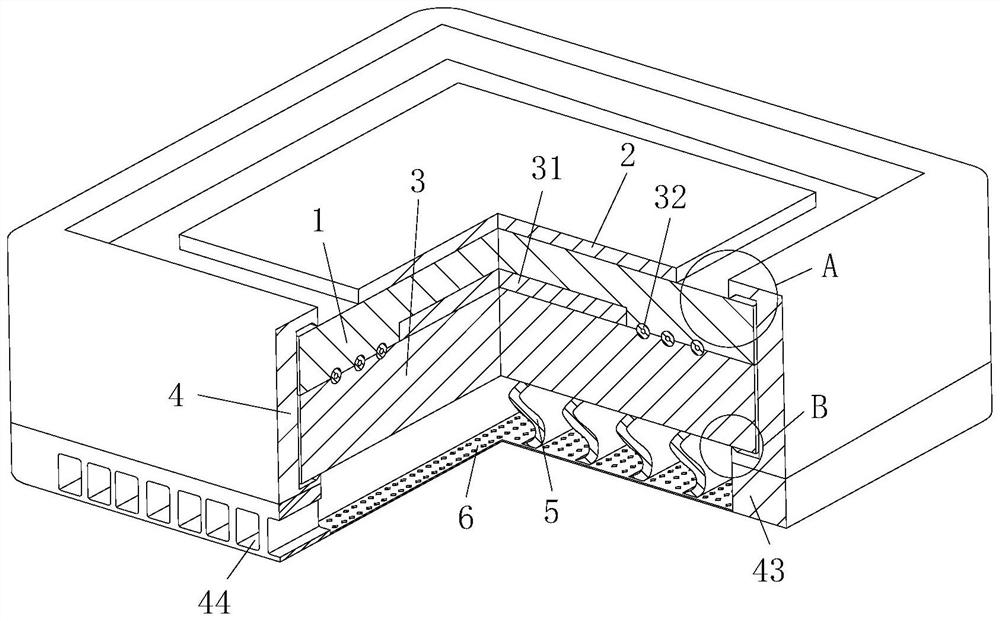

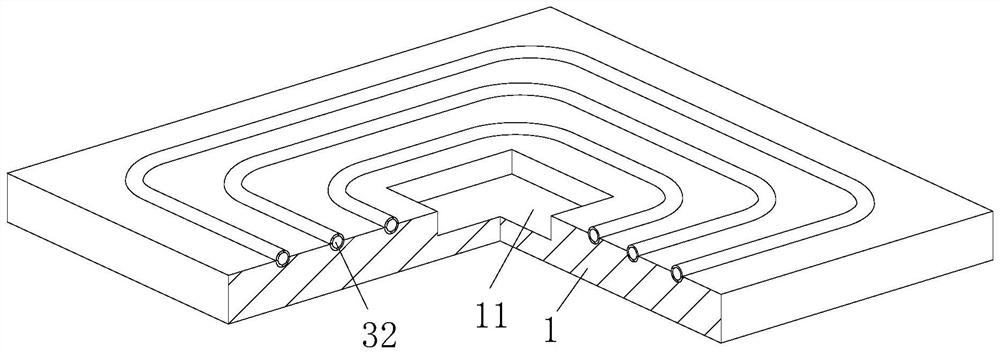

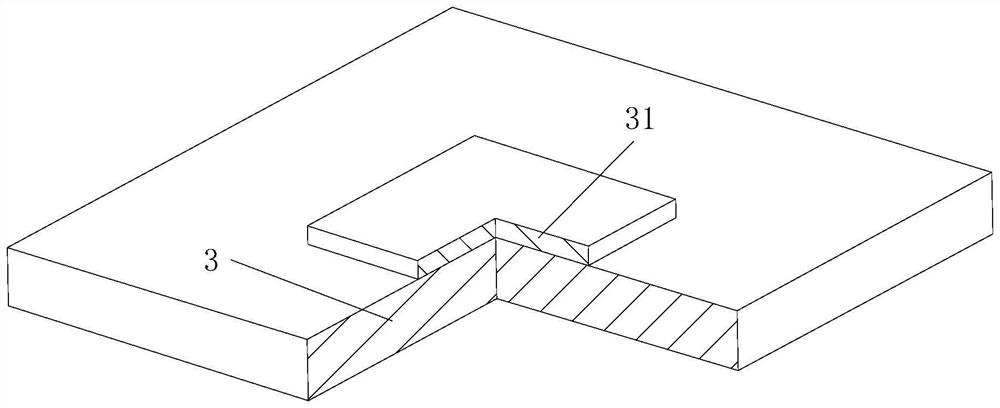

[0037] As an embodiment of the present invention, a reinforcement assembly is installed at the bottom of the PCB board 1, and the reinforcement assembly is composed of multiple groups of "mouth"-shaped reinforcement ribs, and the reinforcement ribs are distributed in concentric circles;

[0038] When working, in order to increase the heat dissipation capacity of the PCB board 1, the PCB board 1 is set as a thin plate, but as the thickness of the PCB board 1 becomes thinner, its mechanical strength will become lower, causing the PCB board 1 to easily deform, and at the same time the bottom of the PCB board 1 Groove 11 is arranged, and the central thickness of PCB board 1 is thinned, and the mechanical strength of PCB board 1 has been further reduced. The reinforced component is composed of concentrically distributed reinforcing ribs. When the PCB board 1 is subjected to the force in the left and right directions, the left and right parts of the reinforced component will generate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com