Device system for hydrogenation reaction by using reboiling furnace as start-up furnace and start-up method

A technology of hydrogenation reaction and reaction device, which is applied in the fields of hydrotreating process, petroleum industry, processing of hydrocarbon oil, etc., can solve the problems of low thermal energy utilization efficiency and complicated procedures, so as to improve process integration, save investment costs, The effect of saving floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

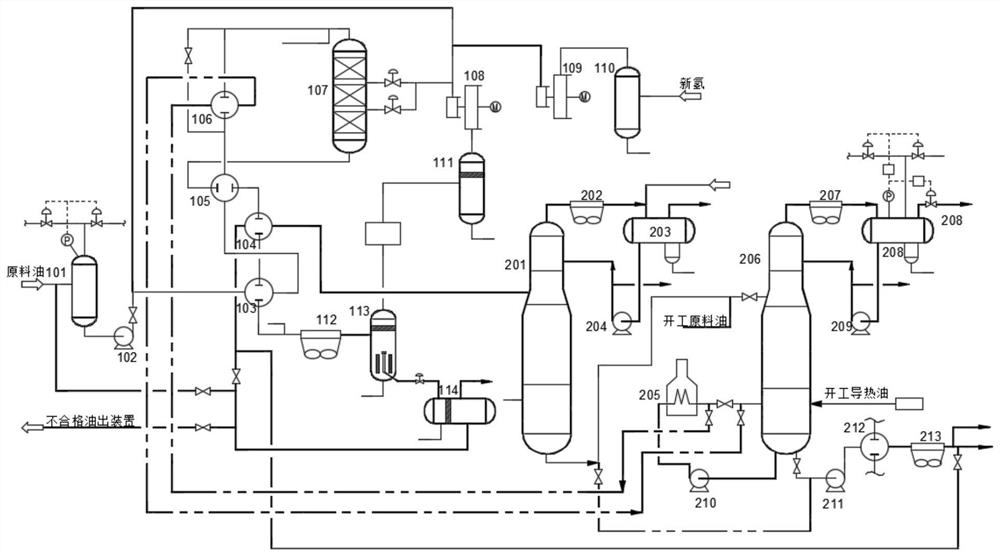

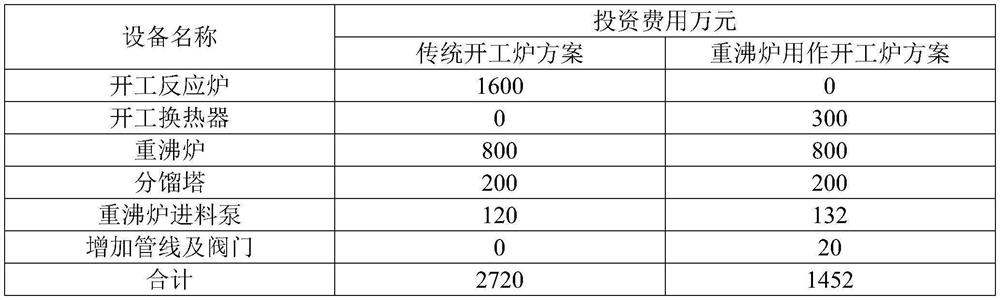

[0114]This embodiment provides a hydrogenation reaction using a reboiler as a start-up furnace device system, specifically a 2 million tons / year diesel hydrogenation device, the hydrogenation reaction uses a reboiler as a start-up furnace start-up system device For the hydrogenation reaction in the above-mentioned specific embodiment, a device system using a reboiler as a start-up furnace is used. The 2 million tons / year diesel hydro-upgrading unit uses straight-run diesel oil as raw material. The main products are heavy naphtha that meets the feedstock of the reforming unit and refined diesel oil that meets the National VI quality standard. The by-products are light naphtha and sulfur-containing liquefaction Gas, low-fraction gas and sulfur-containing dry gas; the operating flexibility of the device is 60-110%, and the annual operating hours are 8,400 hours; the device is composed of a reaction part and a fractionation part. According to the information provided by the cataly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com