Plant source mildew-proof wallpaper glue and preparation method thereof

A wallpaper glue and plant-sourced technology, applied in the preparation of animal glue or gelatin, adhesives, vinyl aromatic copolymer adhesives, etc., can solve the problems of mildew and easy yellowing of wallpaper, and achieve low toxicity and good anti-corrosion Mildew effect, effect of aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1: Add 30g maleic anhydride, 2g dibenzoyl peroxide, 30ml ethyl acetate, stir for 2.5h, add 30ml styrene; heat at 85°C for 2.5h to obtain styrene-maleic anhydride copolymer. Add 30g of styrene-maleic anhydride copolymer and 4g of silane coupling agent KH-550; heat and react at 85°C for 2.5h, cool down, and perform pulse electric field treatment with a pulse frequency of 1kHz and a pulse width of 40μs. 30 pieces were added with absolute ethanol, filtered with suction, washed, and dried in vacuum at 110°C for 2.5 hours to obtain a modified styrene-maleic anhydride copolymer.

[0028] Step 2: Stir soybean polysaccharide and deionized water for 3.5 hours, mix well, add isocyanate and ethyl acetate, stir for 3.5 hours, add butanediol, stir at 55°C for 1.5 hours, cool, wash with deionized water, filter , and dried to obtain the isocyanate modifier; add defatted soy flour, starch, isocyanate modifier, ethyl acetate, stir for 2.5h, and perform pulse electric field treatment...

Embodiment 2

[0034] Step 1: Add 30g of maleic anhydride, 2g of dibenzoyl peroxide, and 30ml of ethyl acetate, stir for 2 hours, add 30ml of styrene; heat at 80°C for 2 hours to obtain a styrene-maleic anhydride copolymer. Add 30g of styrene-maleic anhydride copolymer and 4g of silane coupling agent KH-550; heat and react at 80°C for 2h, cool down, and perform pulse electric field treatment with a pulse frequency of 1kHz, a pulse width of 40μs, and a treatment pulse number of 30 Add absolute ethanol, filter with suction, wash, and dry in vacuum at 100°C for 2 hours to obtain a modified styrene-maleic anhydride copolymer.

[0035]Step 2: Stir soybean polysaccharide and deionized water for 3 hours, mix well, add isocyanate and ethyl acetate, stir for 3 hours, add butanediol, stir at 50°C for 1 hour, cool, wash with deionized water, filter, and dry. Obtain the isocyanate modifier; add defatted soy flour, starch, isocyanate modifier, ethyl acetate, stir for 2 hours, carry out pulse electric fie...

Embodiment 3

[0041] Step 1: Add 30g of maleic anhydride, 2g of dibenzoyl peroxide, and 30ml of ethyl acetate, stir for 3 hours, add 30ml of styrene; heat at 90°C for 3 hours to obtain a styrene-maleic anhydride copolymer. Add 30g of styrene-maleic anhydride copolymer and 4g of silane coupling agent KH-550; heat and react at 90°C for 3h, cool down, and perform pulse electric field treatment with a pulse frequency of 1kHz, a pulse width of 40μs, and a treatment pulse number of 30 Add absolute ethanol, filter with suction, wash, and dry in vacuum at 120°C for 3 hours to obtain a modified styrene-maleic anhydride copolymer.

[0042] Step 2: Stir soybean polysaccharide and deionized water for 4 hours, mix well, add isocyanate and ethyl acetate, stir for 4 hours, add butanediol, stir at 60°C for 2 hours, cool, wash with deionized water, filter, and dry. Obtain an isocyanate modifier; add defatted soybean flour, starch, isocyanate modifier, and ethyl acetate, stir for 3 hours, and perform pulse e...

PUM

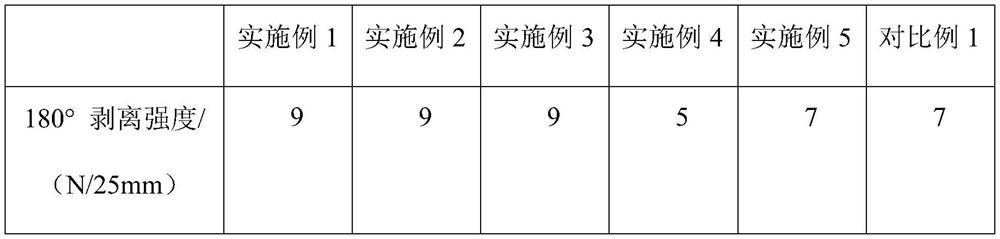

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com