Mining full-length bolting-grouting agent and preparation method thereof

An anchor injection, full-length technology, used in mining equipment, bolt installation, earthwork drilling, etc., can solve the problems of poor diffusion, decreased anchoring force in contact with water, inconvenient use of full-length anchoring, etc., and achieves strong penetration. , The effect of reducing the surface tension and improving the strength of the solidified body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

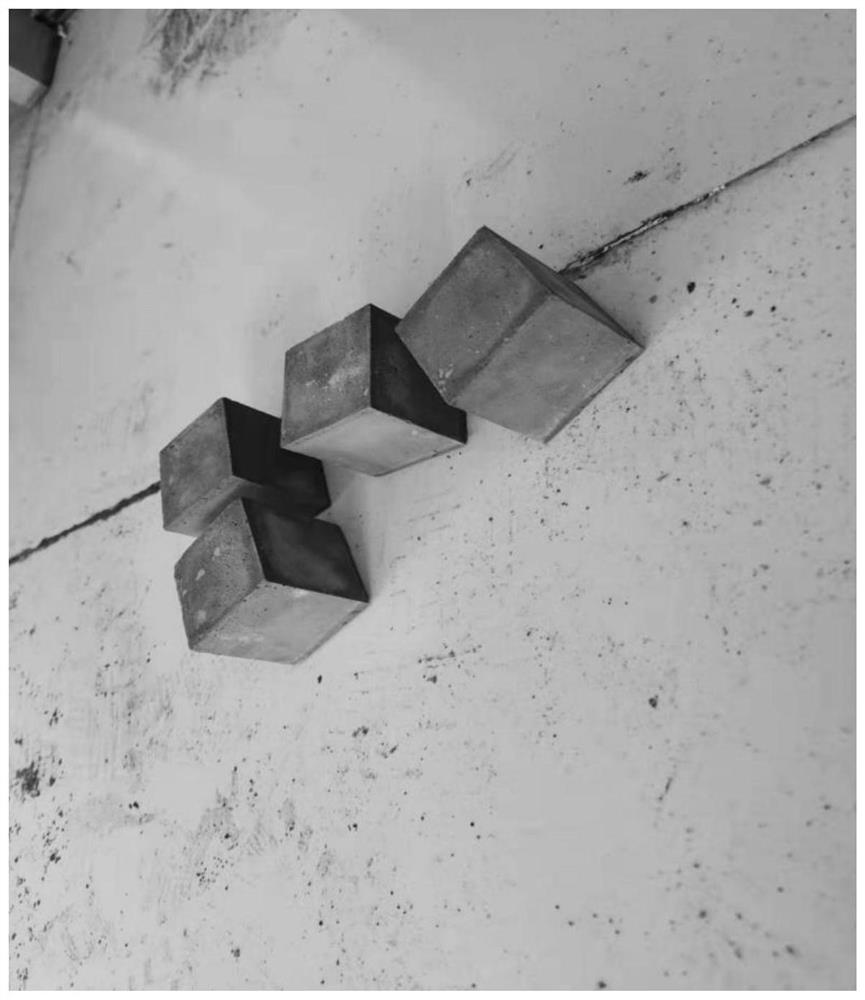

Image

Examples

preparation example Construction

[0054] A preparation method for mine full-length anchor grouting agent, comprising the following steps:

[0055] ⑴Preparation of component A material: Take it at room temperature, put polyphenyl polymethylene polyisocyanate, reactive diluent, surfactant and suspending agent into the reaction kettle and stir thoroughly; then anhydrous chlorinated Calcium and aggregate are added into the reaction kettle and stirred evenly to obtain component A material, and the component A material is packaged into a cylindrical plastic bottle.

[0056] ⑵Preparation of component B materials: at room temperature, add small molecule alcohol and catalyst into the reactor and stir evenly; add inorganic silicate solution, polymer rubber powder, and suspending agent into the reactor and stir evenly, then put Add it into the reaction kettle and stir well to make the sediment completely suspended, that is, to obtain the B component material, and pack the B component material into a cylindrical plastic b...

Embodiment 1

[0070] (1) Preparation of component A materials: take 40 kg of polyphenyl polymethylene polyisocyanate, 10 kg of reactive diluent, 1 kg of surfactant, 10 kg of anhydrous calcium chloride, 20 kg of aggregate, suspending agent 5 kg. At normal temperature, put polyphenyl polymethylene polyisocyanate, reactive diluent, surfactant and suspending agent into the reactor and stir well; then add anhydrous calcium chloride and aggregate into the reactor Stir evenly to obtain the component A material, and pack the component A material into a cylindrical plastic bottle.

[0071] (2) Preparation of component B materials: Take 40 kg of inorganic silicate solution, 12 kg of small molecule alcohol, 0.1 kg of polymer rubber powder, 0.1 kg of catalyst, 2 kg of suspending agent, and 30 kg of aggregate. At normal temperature, add the small molecule alcohol and catalyst into the reactor and stir evenly; add the inorganic silicate solution, polymer rubber powder, and suspending agent into the reac...

Embodiment 2

[0080] (1) Preparation of component A materials: Take 45 kg of polyphenyl polymethylene polyisocyanate, 15 kg of reactive diluent, 2 kg of surfactant, 15 kg of anhydrous calcium chloride, 25 kg of aggregate, suspending agent 5 kg. At normal temperature, put polyphenyl polymethylene polyisocyanate, reactive diluent, surfactant, and suspending agent into the reactor and stir fully; then add the aggregate into the reactor and stir evenly to obtain Component A material, package the component A material into a cylindrical plastic bottle.

[0081] (2) Preparation of component B materials: Take 45 kg of inorganic silicate solution, 16 kg of small molecule alcohol, 0.3 kg of polymer rubber powder, 0.1 kg of catalyst, 2 kg of suspending agent, and 35 kg of aggregate. At room temperature, add small molecule alcohol and catalyst into the reaction kettle and stir evenly; then add inorganic silicate solution, polymer rubber powder, and suspending agent into the reaction kettle and stir ev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com