Anaerobic membrane bioreactor and organic sewage treatment method

A technology of anaerobic membrane biology and organic sewage, applied in the field of sewage treatment, can solve the problems of membrane pollution, low, need to configure biogas recovery and pressurization equipment, destroy sludge particles, etc., to achieve simple cleaning and maintenance, excellent solid-liquid Separation effect, the effect of low energy consumption in operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

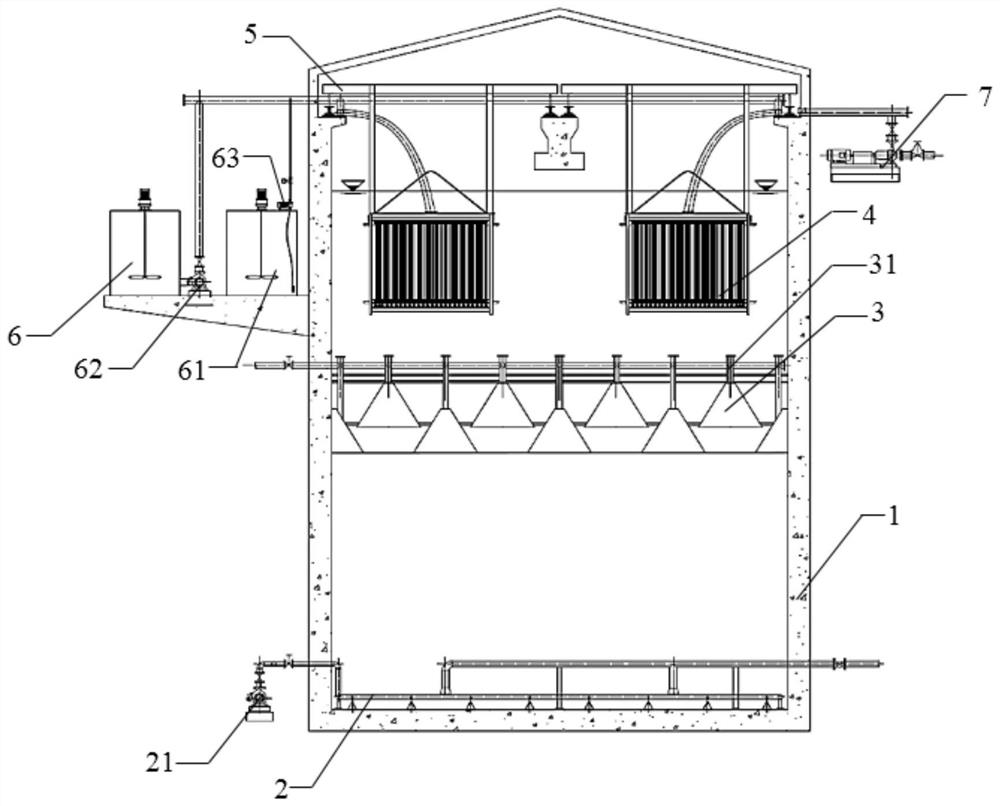

[0080] The present embodiment provides a method for organic sewage treatment, which specifically includes the following steps:

[0081] (A) The organic sewage to be treated enters the water inlet pipe 2 after being boosted by the lift pump 21, and enters the sludge bed in the first anaerobic zone through the conical reflector, and the macromolecular organic pollutants in the organic sewage are absorbed by the sludge bed. The hydrolytic acidifying bacteria decompose into small molecules, which are further decomposed by methanogenic bacteria to obtain biogas and mud-water mixture; among them, the temperature of the first anaerobic zone is 25°C, the pH value is 7.2, and the rising flow rate of mud-water mixture is 0.5 m / h, the average sludge concentration in the first anaerobic zone is 15g / L.

[0082] (B) The biogas enters the three-phase separation zone, is collected by the three-phase separator 3 and enters the degassing equipment through the exhaust pipe 31 for further process...

Embodiment 2

[0084] The present embodiment provides a method for organic sewage treatment, which specifically includes the following steps:

[0085] (A) The organic sewage to be treated enters the water inlet pipe 2 after being boosted by the lift pump 21, and enters the sludge bed in the first anaerobic zone through the conical reflector, and the macromolecular organic pollutants in the organic sewage are absorbed by the sludge bed. The hydrolytic acidifying bacteria decompose into small molecules, which are further decomposed by methanogenic bacteria to obtain biogas and mud-water mixture; among them, the temperature of the first anaerobic zone is 30°C, the pH value is 7.6, and the rising flow rate of mud-water mixture is 0.8 m / h, the average sludge concentration in the first anaerobic zone is 20g / L.

[0086] (B) The biogas enters the three-phase separation zone, is collected by the three-phase separator 3 and enters the degassing equipment through the exhaust pipe 31 for further process...

Embodiment 3

[0088] The present embodiment provides a method for organic sewage treatment, which specifically includes the following steps:

[0089] (A) The organic sewage to be treated enters the water inlet pipe 2 after being boosted by the lift pump 21, and enters the sludge bed in the first anaerobic zone through the conical reflector, and the macromolecular organic pollutants in the organic sewage are absorbed by the sludge bed. The hydrolytic acidifying bacteria decompose into small molecules, which are further decomposed by methanogenic bacteria to obtain biogas and mud-water mixture; among them, the temperature of the first anaerobic zone is 35°C, the pH value is 8.0, and the rising flow rate of mud-water mixture is 1.0 m / h, the average sludge concentration in the first anaerobic zone is 25g / L.

[0090] (B) The biogas enters the three-phase separation zone, is collected by the three-phase separator 3 and enters the degassing equipment through the exhaust pipe 31 for further process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com