Screen printing device for packaging

A technology for screen printing device and packaging, which is applied to screen printing machines, printing machines, printing machines, etc. It can solve the problems of partial printing defects of products, affecting the appearance of products, and large color difference of finished products, so as to achieve beautiful products and high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

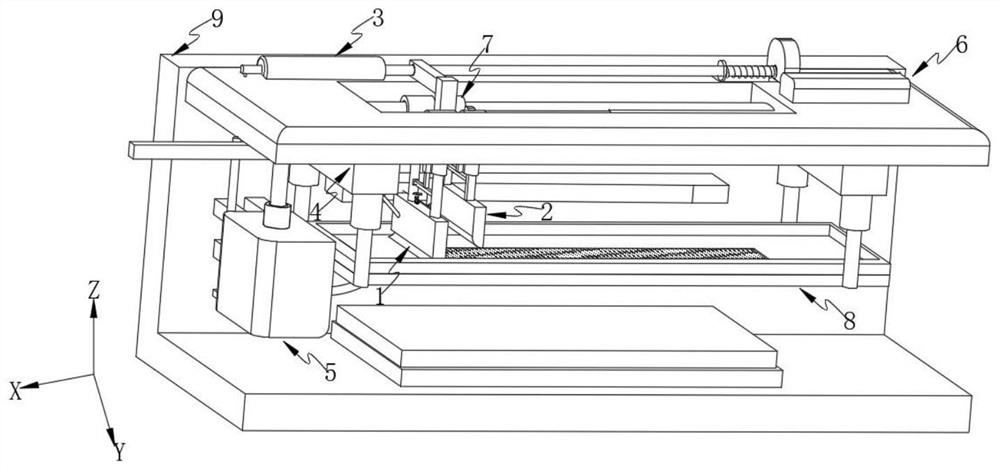

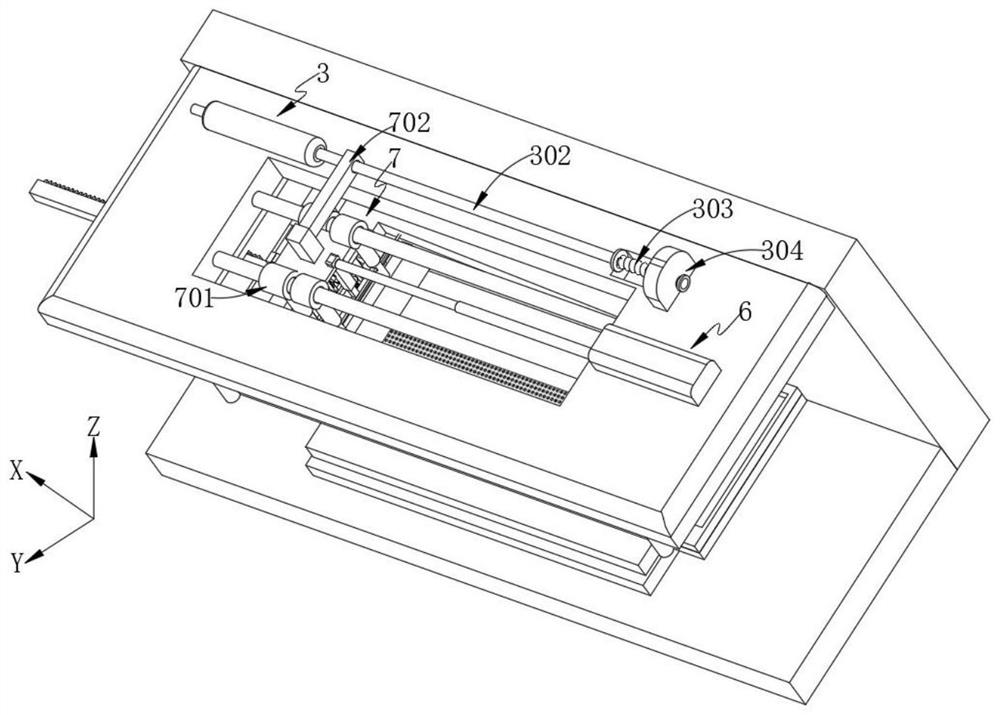

[0066] Such as Figure 1-2 Shown, a kind of screen printing device for packaging comprises:

[0067] Ink control unit 3, and

[0068] The ink brushing unit 2, the ink distribution unit 1, the ink separation unit 4, and the collection unit 5 are sequentially arranged at the lower part of the ink control unit 3;

[0069] Under the control of the ink control unit 3, the ink is quantitatively absorbed from the collection unit 5 into the ink separation unit 4, and then the ink control unit 3 inputs the ink in the ink separation unit 4 into the ink distribution unit 1, and passes through the ink distribution unit 1. Cooperate with ink brushing unit 2 to carry out reciprocating printing work under the premise of the same ink viscosity each time.

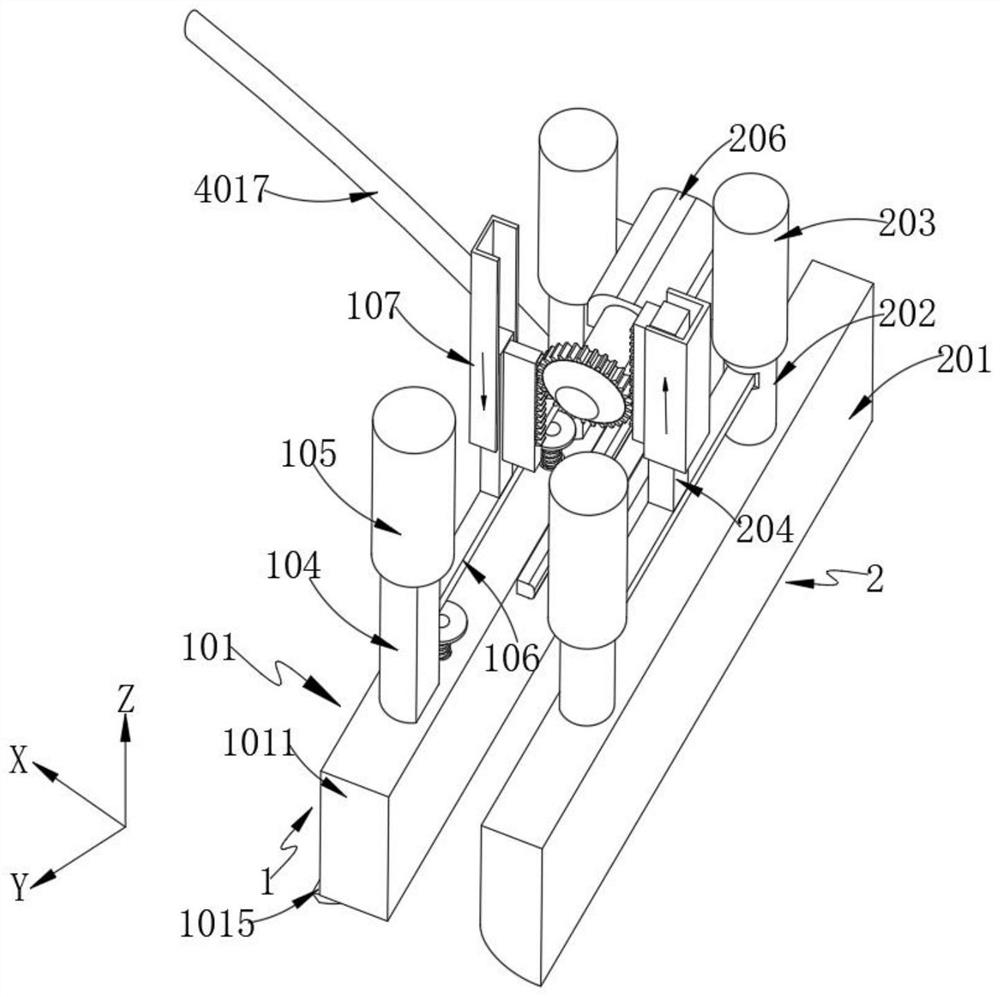

[0070] As an improvement, such as Figure 3-6 As shown, the ink distribution unit 1 includes:

[0071] Ink distribution component 101;

[0072] Ink pressing assembly 102, the ink pressing assembly 102 for discharging the ink inside the...

Embodiment 2

[0117] Such as image 3 , Figure 6-7 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0118] Described brushing ink unit 2 comprises:

[0119] A brush plate 201, the lower end of the brush plate 201 is set in a slanted shape;

[0120] The second lifting mechanism 202, two second lifting mechanisms 202 for adjusting the height of the brush plate 201 are connected to the upper end of the brush plate 201;

[0121] A second driven assembly 204, the second driven assembly 204 is connected between the two second lifting mechanisms 202;

[0122] The driving device 206 is used to switch the driving device of the ink distribution unit 1 and the ink brushing unit 2 to engage with the first lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com