Homogenization device and method of garbage

A technology for domestic waste and slurry tank, which is applied in mixing methods, chemical instruments and methods, mixers with rotary stirring devices, etc., can solve the problems of equipment maintenance costs, high costs, easy to wear blades, etc., and achieves easy cleaning and maintenance. , the effect of increasing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

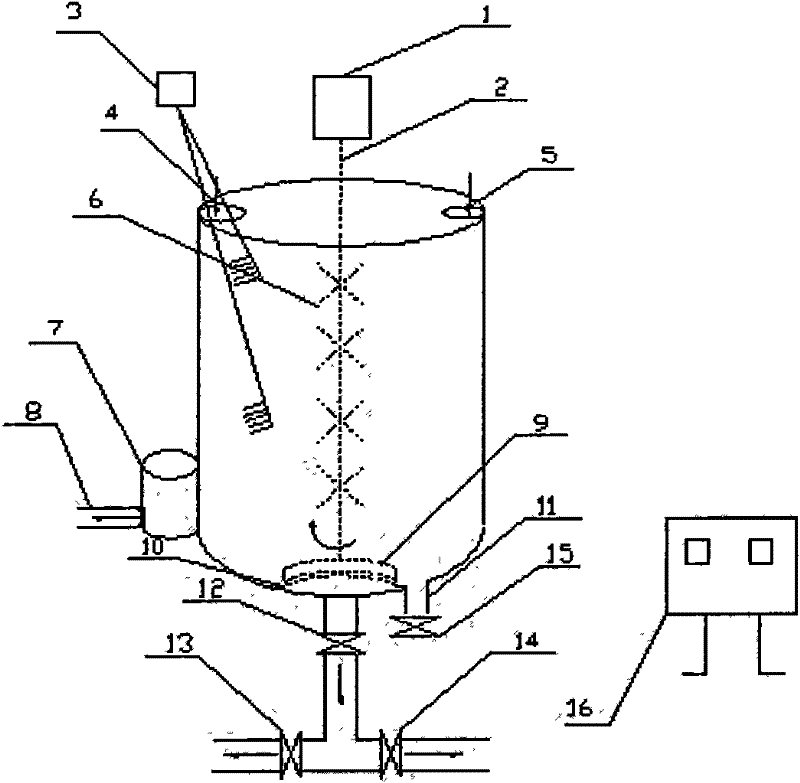

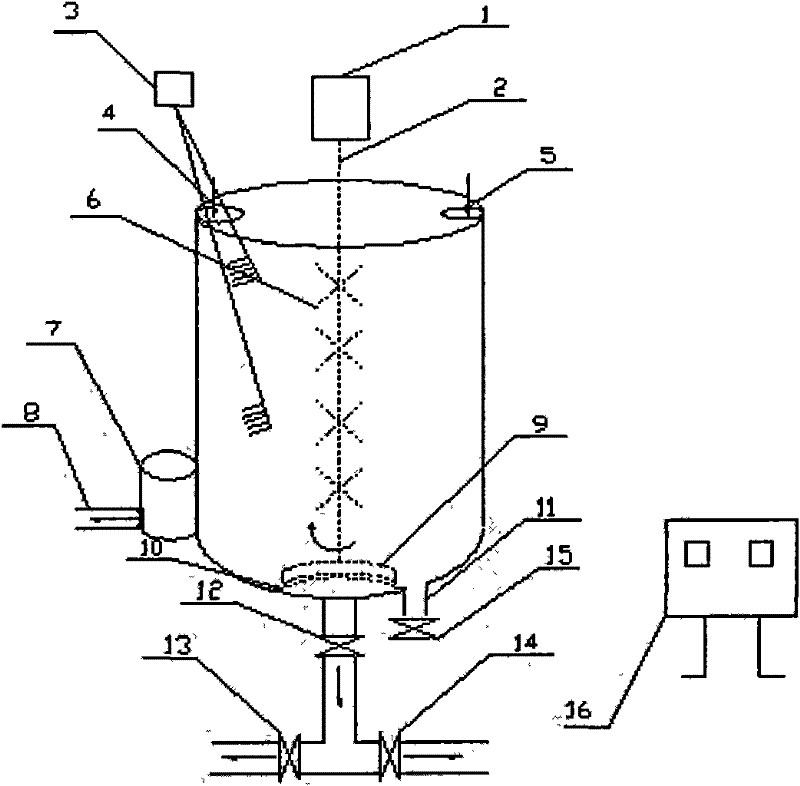

[0018] refer to figure 1 An example of application of the device and method is illustrated.

[0019] First, pour water into the homogenizing tank through the water inlet, and when the water level reaches half of the height of the homogenizing tank, slowly add domestic garbage that needs to be homogenized through the feeding port, the liquid-solid ratio is 10:1, and the water and domestic After the garbage is added, adjust the stirring speed of the motor to 70r / min. After stirring for 6 minutes, the heavy materials in the domestic waste, such as stones, will gradually enter the heavy material storage groove, and the fine materials in the domestic waste, such as fine sand, will pass through the fine materials. The outlet plate enters the bottom outlet area. At this time, the first pneumatic valve on the discharge pipeline at the bottom of the homogenization tank and the second pneumatic valve for discharging fine materials are controlled by the PLC controller, and the fine mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com