Homogenizing effect optimization method for the glass substrate manufacturing stirring system

A stirring system and optimization method technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as inability to quantify experimental data, existence of errors, inability to compare densities, etc., to ensure homogenization efficiency and accuracy Sex, improve the effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

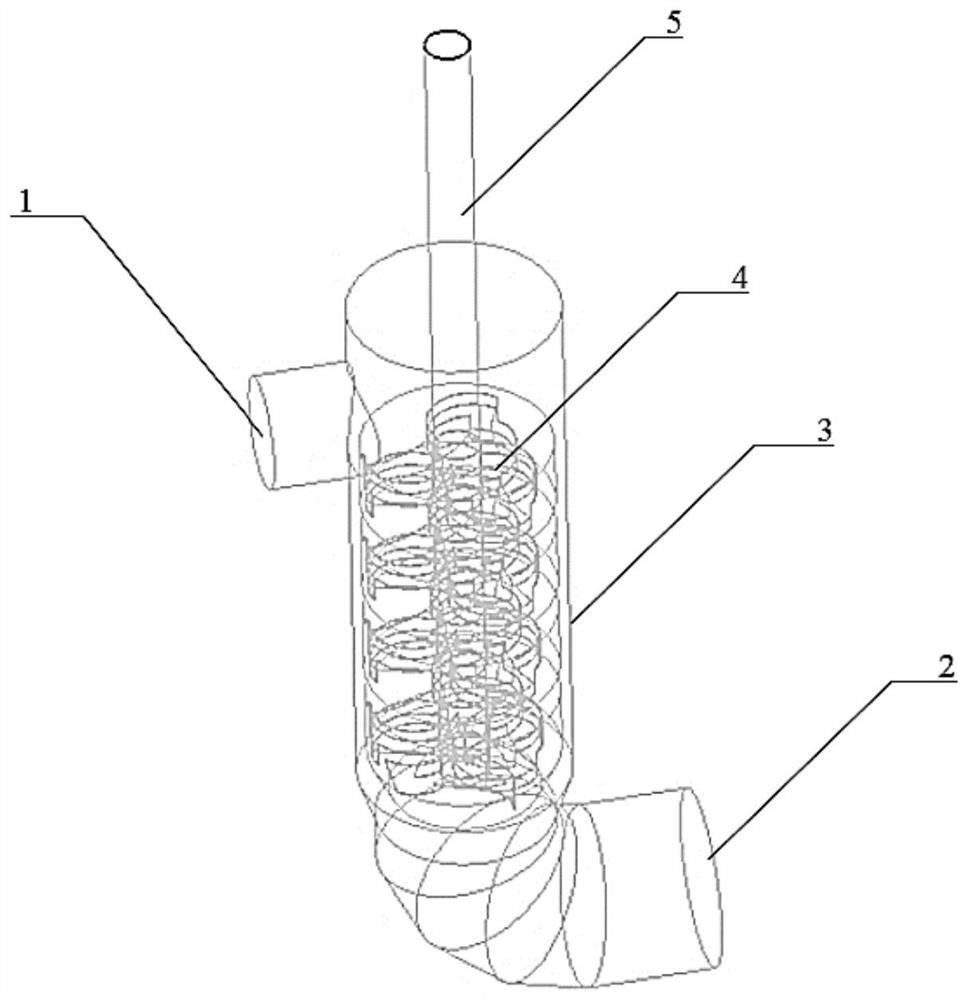

[0049] When the stirring system of the present invention is working, the stirrer is driven by the transmission mechanism and rotates at a constant speed according to the set speed, so as to stir the molten glass liquid entering the stirring barrel through the inlet. The molten glass itself has thermal conductivity, and the temperature of the molten glass may have reached the same temperature at the back of the mixing tank, which is not convenient for studying the stirring effect, so the thermal conductivity of the molten glass is artificially reduced to 1 of the original thermal conductivity / (1000~)~10 / 1000.

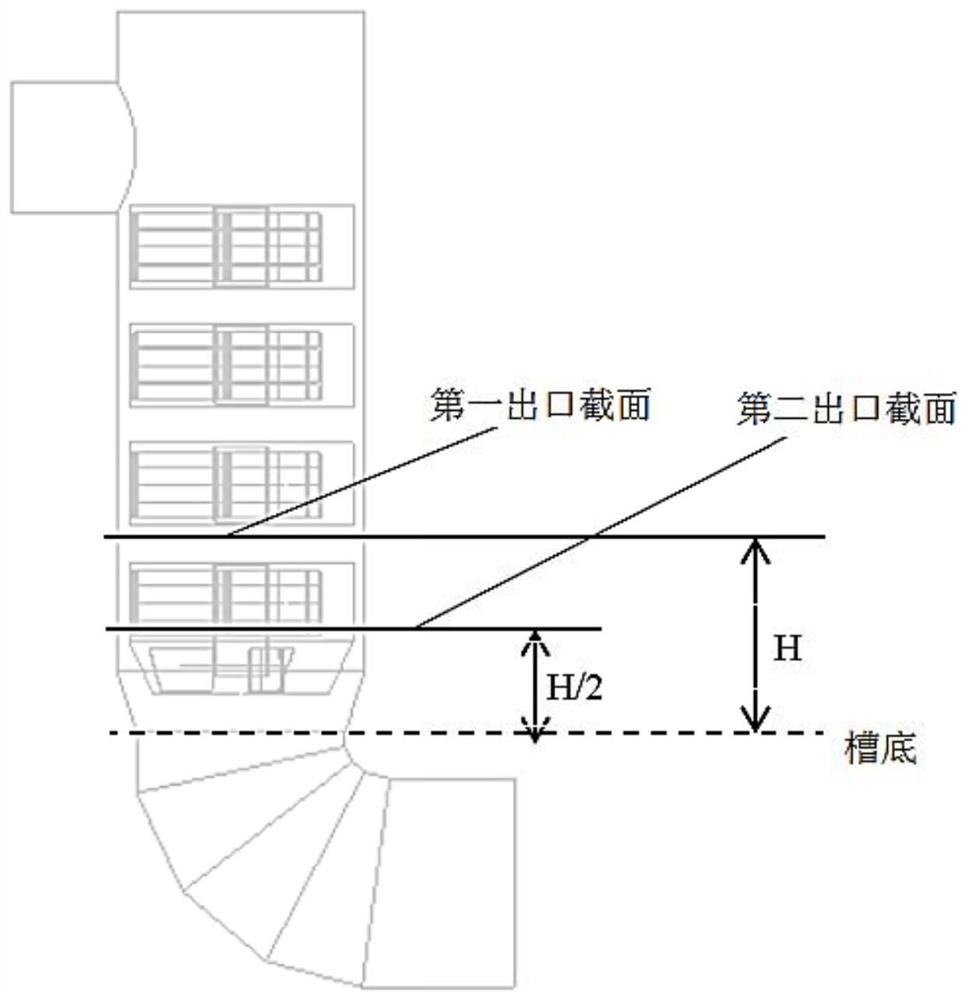

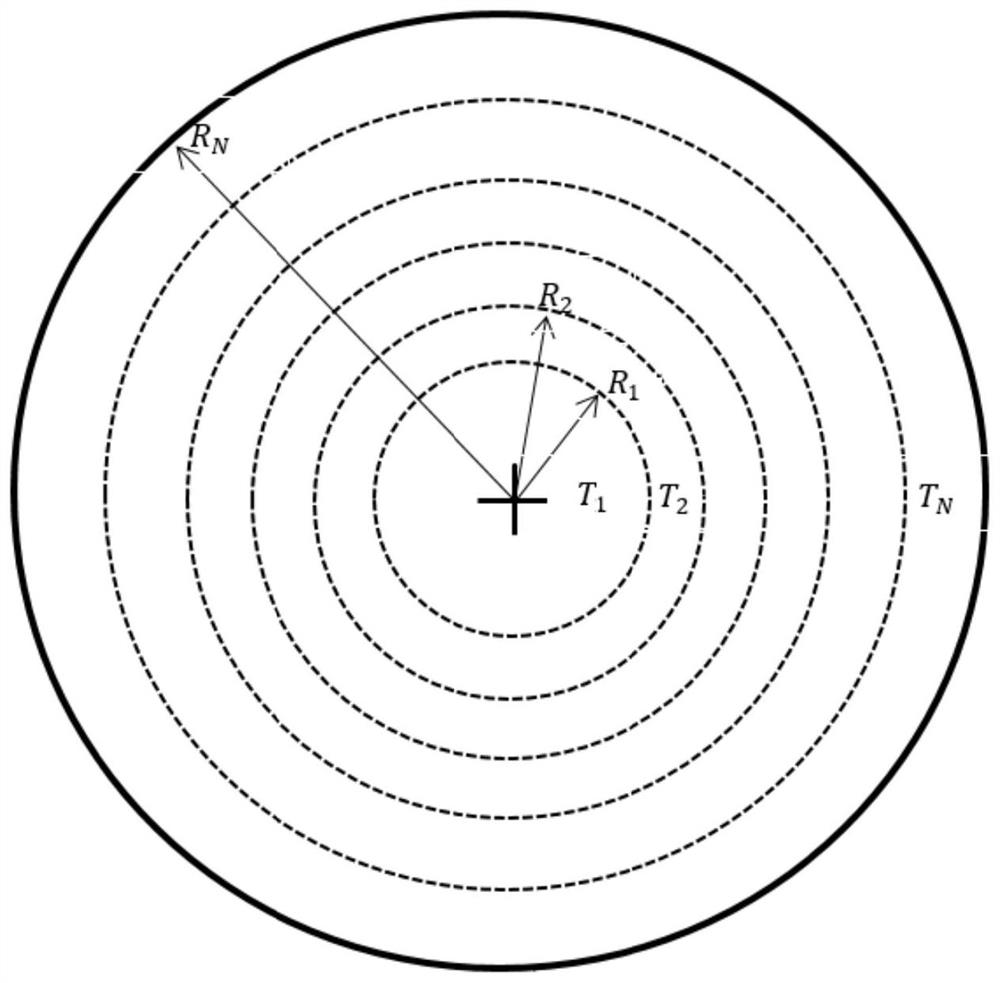

[0050] The range of the outlet section of the stirring system is H from the bottom of the stirring tank, and the distance from the first outlet section to the bottom of the mixing system is The output temperature distribution range of the first outlet section is calculated by stirring simulation to obtain the extreme difference of ΔT 1 =T 1max -T 1min ; The distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com