Zinc oxide silicon-based pillared illite-montmorillonite clay composite material as well as preparation method and application thereof

A technology of imonic clay and composite adsorption material, which is applied in the field of zinc oxide silicon-based pillared imonic clay composite material and preparation thereof, can solve the problems of limited adsorption capacity of imonic clay, influence on the removal effect of Rhodamine B, and the like, and achieves the preparation of The process is easy to control, the value of industrial utilization is high, and the effect of low environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

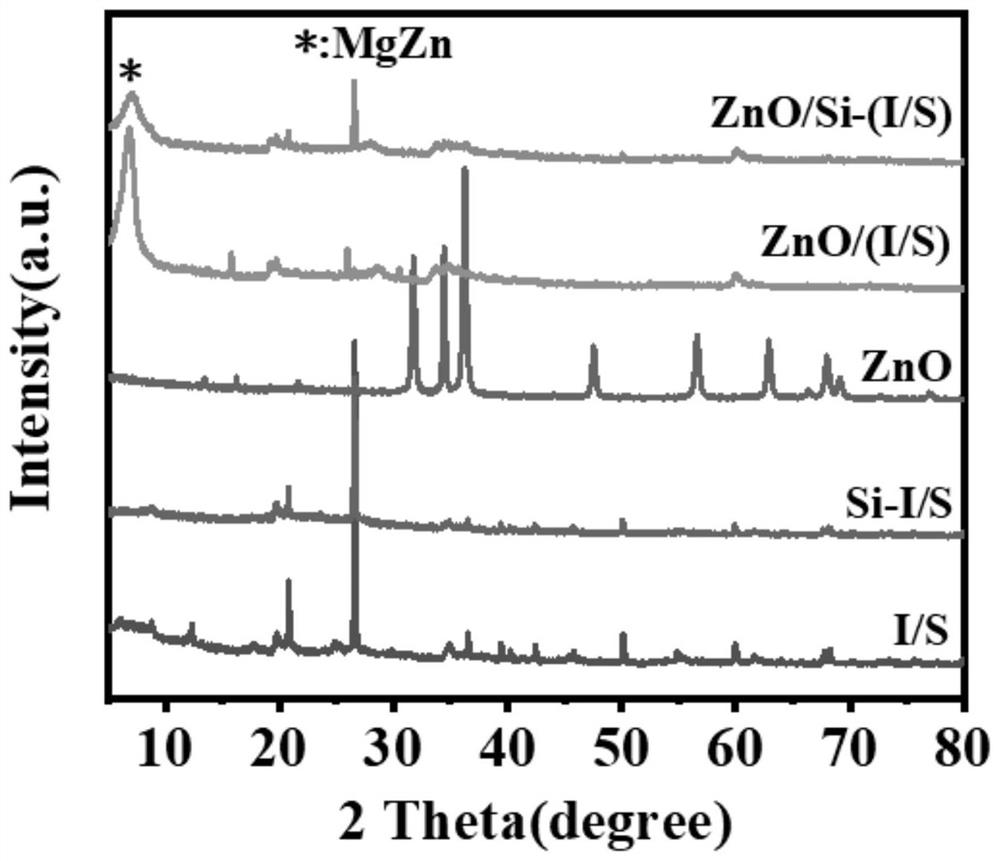

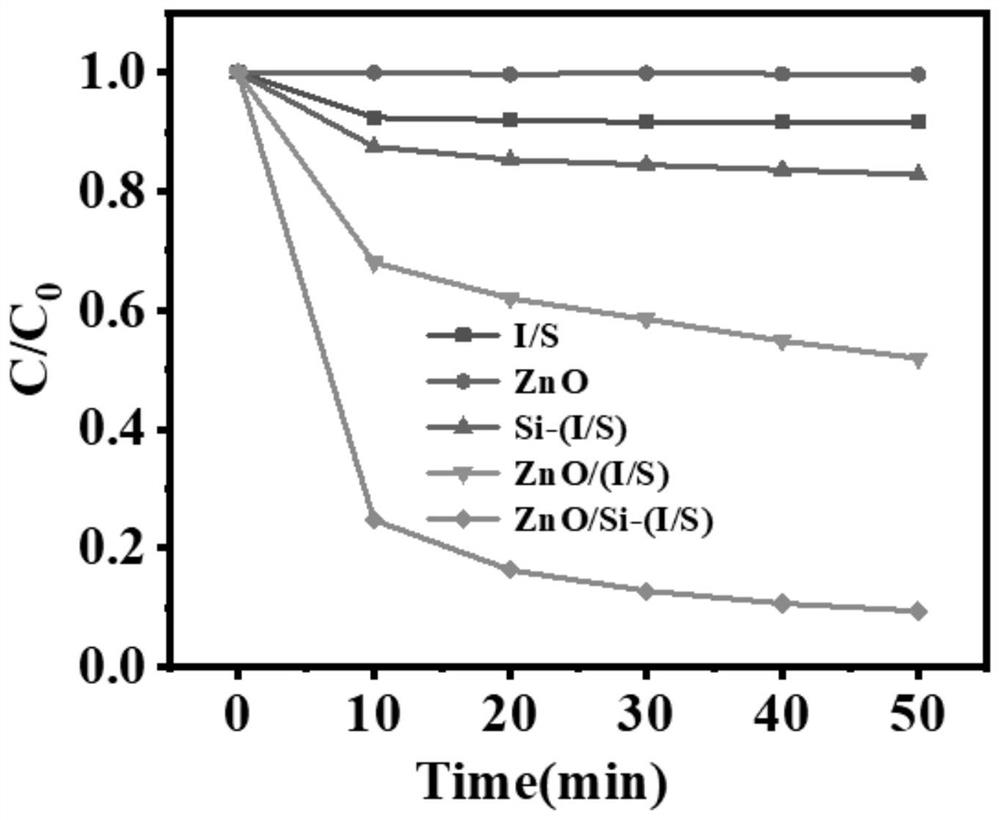

[0031] The invention relates to a composite adsorption material of zinc oxide silicon-based pillared imonite clay, comprising: zinc oxide and silicon-based pillared imonite clay.

[0032] The Yimeng clay in this example is taken from Guangxi Fangchenggang Strong Building Materials Co., Ltd. The clay is formed by stacking silicon-oxygen tetrahedrons and aluminum-oxygen octahedrons in 1:1 and 2:1 patterns, with -OH between layers. 、Al 3+ 、K + 、Na + Plasma; its specific surface area, average pore diameter, and total pore volume are 40.9m 2 / g, 11.4nm, 0.1166cm 3 / g. The water in this example is distilled water, and the specifications of other medicines used in this example are analytically pure.

Embodiment 2

[0034] The invention relates to a composite adsorption material of zinc oxide silicon-based pillared imonite clay, comprising: zinc oxide and silicon-based pillared imonite clay.

[0035] The preparation method of zinc oxide silicon-based pillared Imon clay composite adsorption material comprises the following steps:

[0036] Step 1. Mix and stir the imonite clay, sodium carbonate, and distilled water at room temperature for 24 hours to obtain a sodium-modified imonite clay suspension;

[0037] Step 2, mixing absolute ethanol, (16% by mass fraction) hydrochloric acid, and tetraethyl silicate and sealing and aging at room temperature for 1 hour to obtain a silicon-based columnar agent;

[0038] Step 3. Add the silicon-based columning agent dropwise to the sodium-modified Imond clay suspension under the condition of stirring at a temperature of 50°C (a constant-pressure dropping funnel is used for the dropwise addition), and continue stirring for 3 hours after the dropwise addit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com