Two-way temperature control circulating liquid supply system of laboratory equipment and control method

A supply system and laboratory technology, which is applied in the dual-circuit temperature-controlled circulating water supply system and control field, can solve problems such as affecting the consistency of test results, low air cooling efficiency, and increasing laboratory infrastructure costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

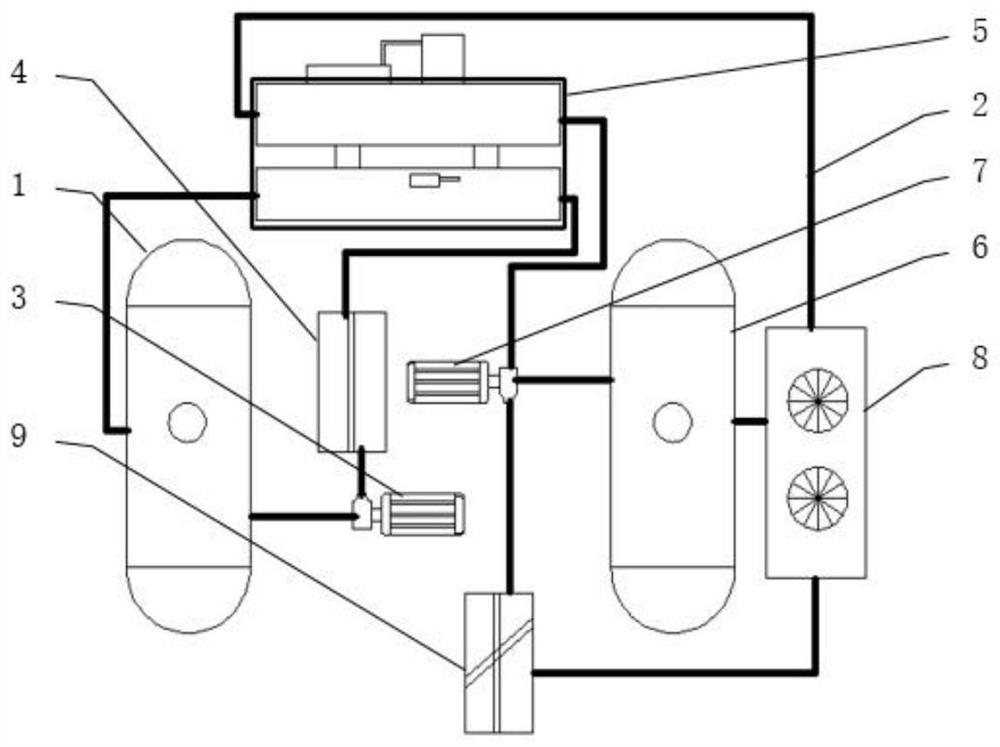

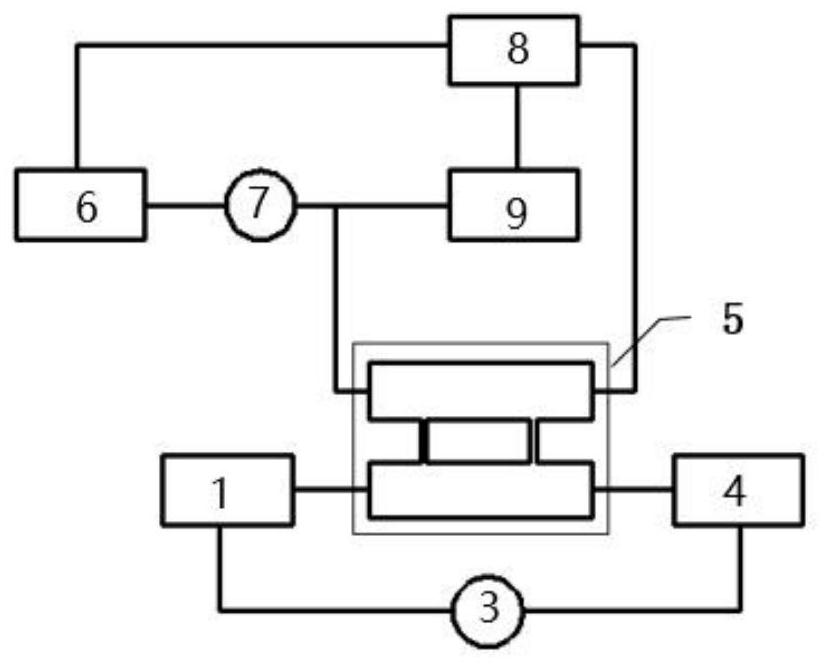

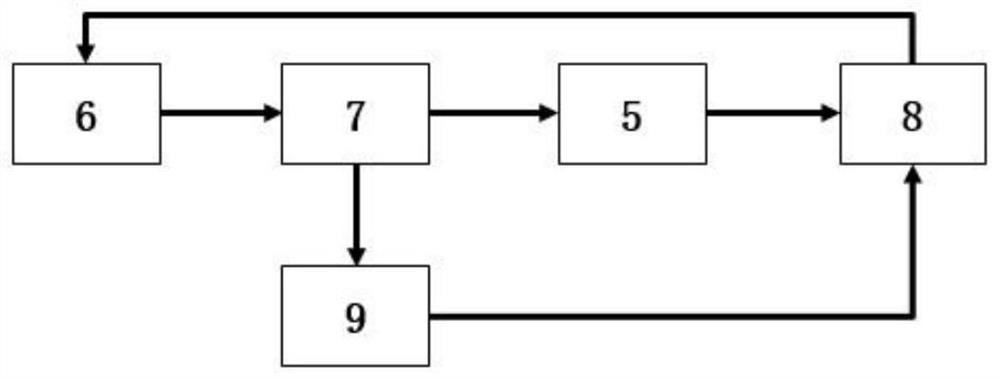

[0068] Such as figure 1 , figure 2 As shown, the present invention includes that the present invention includes circuit one for providing low-temperature circulating fluid for the low-temperature medium cooling equipment group 4 in the laboratory, and circuit two for providing normal-temperature circulating fluid for the normal-temperature medium cooling equipment group 9 in the laboratory, and A dual-temperature circulating water unit 5 connected between loop one and loop two; loop one provides low-temperature circulating water for laboratory equipment, and loop two provides normal temperature circulating water for laboratory equipment. The two circuits of circulating water can be controlled centrally, according to actual Cool the corresponding equipment in the laboratory respectively. Circuit 1 includes low-temperature medium storage tank 1, the outlet of low-temperature medium storage tank 1 communicates with the inlet of the cooling circulation system of low-temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com