Double packer steam injection integrated device and method for heavy oil development in oilfield

A technology of packer and steam injection, which is applied in the direction of production fluid, sealing/isolation, earthwork drilling and production, etc. It can solve the problems of waste of heat and injection materials, increase labor intensity of workers, reduce the service life of oil wells, etc., and achieve reduction in construction procedures, avoiding loss of matter and energy, and reducing the effect of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

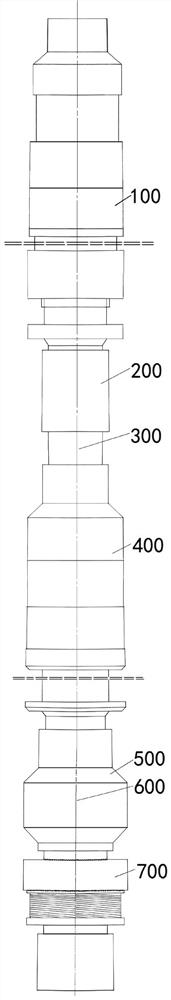

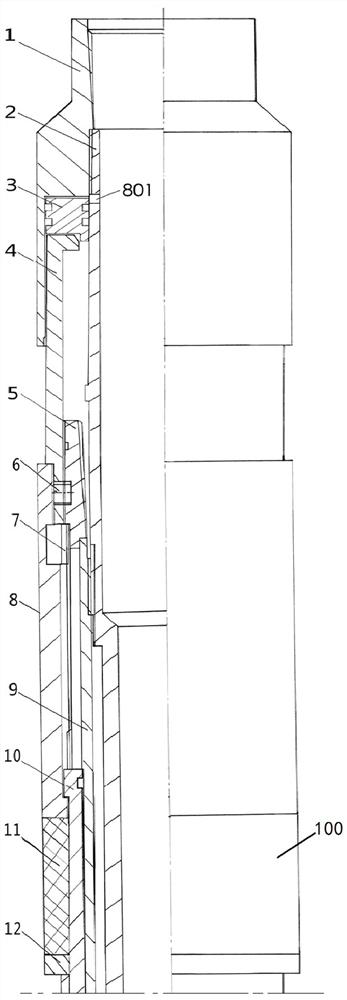

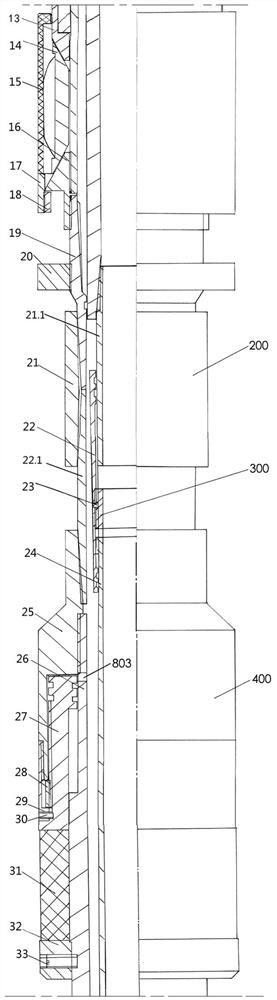

[0030] Embodiment 1, with reference to Figure 1-4 , an oilfield heavy oil development mentioned in the present invention adopts a double packer steam injection integrated device, including an upper packer 100, a lower packer 400 and a steam injection valve 500, and the lower end of the upper packer 100 is installed with a lower The packer 400, the lower end of the lower packer 400 is equipped with a steam injection valve 500, which also includes a layer spacer pipe 200, a connecting core pipe 300, a seat sealer 600, and a one-way oil recovery device 700. The upper packer The lower end of the device 100 is connected to the lower packer 400 through the layer spacer pipe 200 and the connecting core pipe 300, and the lower end of the steam injection valve 500 is installed with a seater 600 and a one-way oil recovery device 700;

[0031] The inner cavity of the upper packer 100 is installed with a core tube 2, the upper end of the core tube 2 is connected to the upper joint 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com