Production, calculation, heating and verification method for reducing strength difference of mandrel

A production method and mandrel technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve problems such as difficult selection of unqualified products, and achieve the effect of improving yield and reducing strength difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

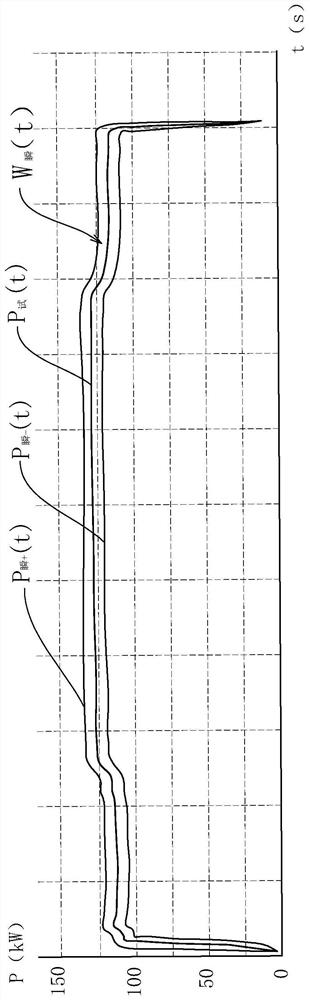

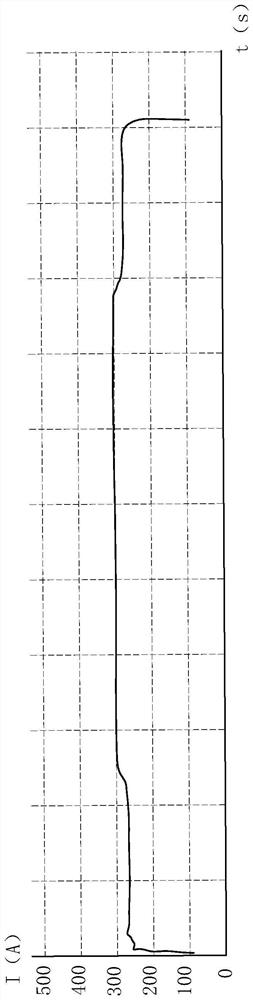

[0074] The embodiment of the present application discloses a heating method for controlling the depth of the quench hardened layer. The above-mentioned heating method in the embodiment of the present application heats the mandrel made of 40Cr material. The requirements of the mandrel are: the surface hardness after quenching is HRC52-57, and the static torsional strength is 1500-1800 N·m. The following application will provide further details.

[0075] A production, calculation, heating and verification method for reducing the difference in the strength of mandrels, comprising:

[0076] S1: Calculate the depth of the quench hardened layer required by the mandrel according to the design strength. This embodiment adopts the design method of the quench hardened layer depth that meets the strength requirements. The specific method is as follows:

[0077] S11: Measure the outer diameter of each section of the mandrel with a screw micrometer, and determine the minimum outer diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com