Method for promoting yield of methane produced by straw anaerobic fermentation through ethanol and biochar and application

A combination of biological and anaerobic fermentation technology, applied in the direction of fermentation, adding compounds to stimulate growth, waste fuel, etc., can solve the problems of low biogas production, low gas production rate, long fermentation cycle, etc., to improve biogas production, porosity Effects of complex structure and improved utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1. Pretreatment:

[0043] Rapeseed straw was pretreated with 1% NaOH solution at 60°C for 48 hours, and the liquid-solid ratio was 10mL / g.

[0044] 2. Anaerobic fermentation

[0045]Anaerobic fermentation was carried out in a 500 mL fermentation bottle. 8 g of pretreated rape straw was added to 240 g of fresh inoculated sludge (TS was 6.67%, VS was 4.71%; the dry mass ratio of rape straw to inoculated sludge was 1:2) and 150mL of distilled water, the total working volume of the fermentation bottle is about 400mL, the initial pH value is 7.0, in order to avoid acidification during the start-up period, 1g of sodium bicarbonate is added to provide a buffer, the amount of biochar added is 2.5g, and the amount of ethanol added is 1.5mL; Carry out anaerobic fermentation, and the anaerobic fermentation temperature is set at 37°C. During the experiment, the biogas production was measured by the drainage method every 12 hours, and the biogas was collected with a gas collection...

Embodiment 2

[0047] Using the method of Example 1, the effect of adding ethanol alone for anaerobic fermentation was investigated.

[0048] 1. Pretreatment

[0049] Rapeseed straw was pretreated with 1% NaOH solution at 60°C for 48 hours, and the liquid-solid ratio was 10mL / g.

[0050] 2. Anaerobic fermentation experiment

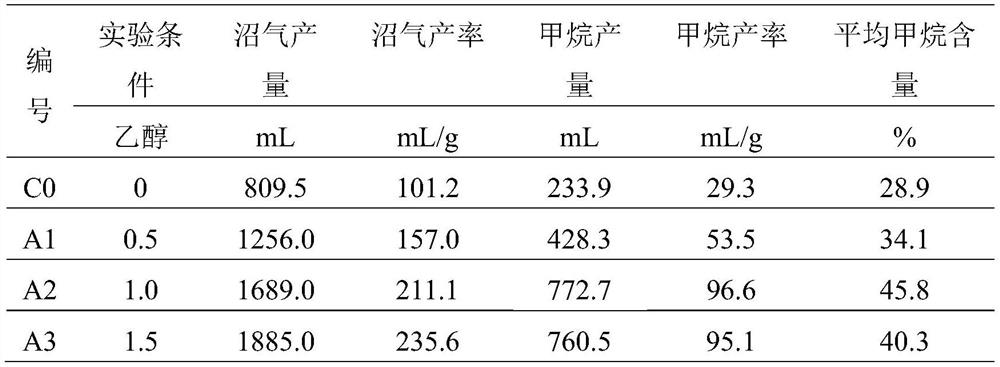

[0051] Anaerobic fermentation was carried out in a 500 mL fermentation bottle. 8 g of pretreated rape straw was added to 240 g of fresh inoculated sludge (TS was 6.67%, VS was 4.71%; the dry mass ratio of rape straw to inoculated sludge was 1:2) and 150mL of distilled water, the total working volume of the fermentation bottle is about 400mL, and the initial pH value is 7.0. In order to avoid acidification during the start-up period, 1g of sodium bicarbonate is added to provide a buffer, and nitrogen is introduced for anaerobic fermentation. The anaerobic fermentation temperature is set at 37°C. The time is 20 days. In order to study the effect of ethanol addition on ...

Embodiment 3

[0058] Using the method of Example 1, the effect of adding biological carbon anaerobic fermentation alone was investigated.

[0059] 1. Pretreatment

[0060] Rapeseed straw was pretreated with 1% NaOH solution at 60°C for 48 hours, and the liquid-solid ratio was 10mL / g.

[0061] 2. Anaerobic fermentation experiment

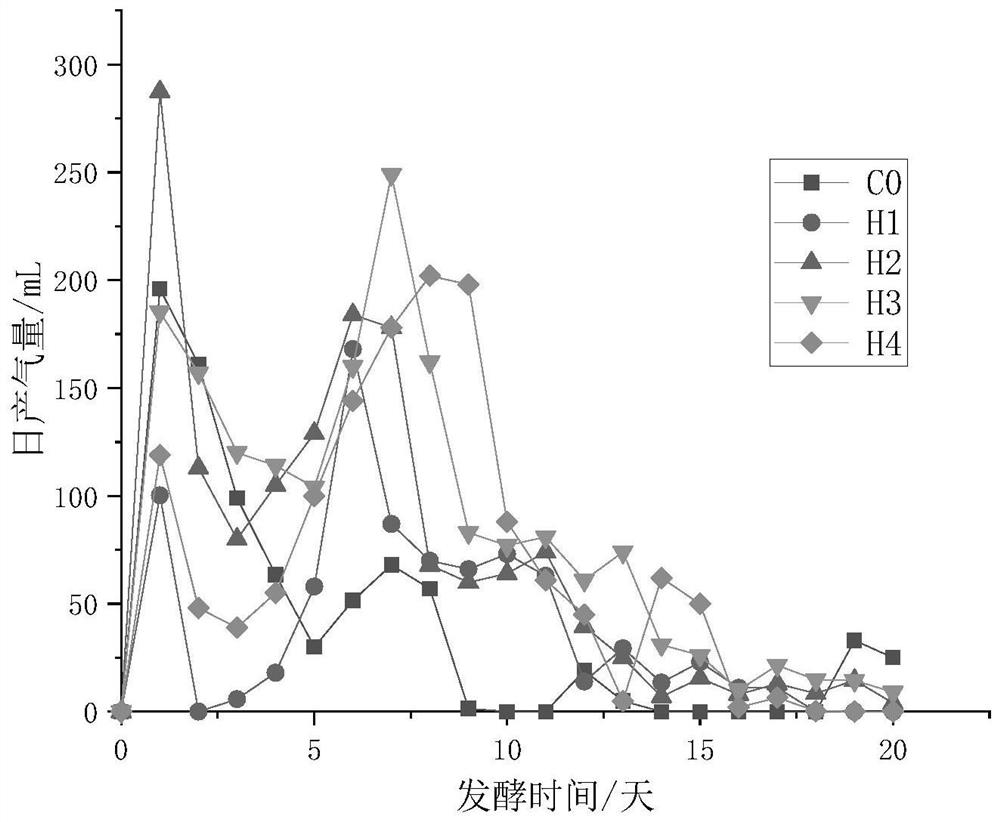

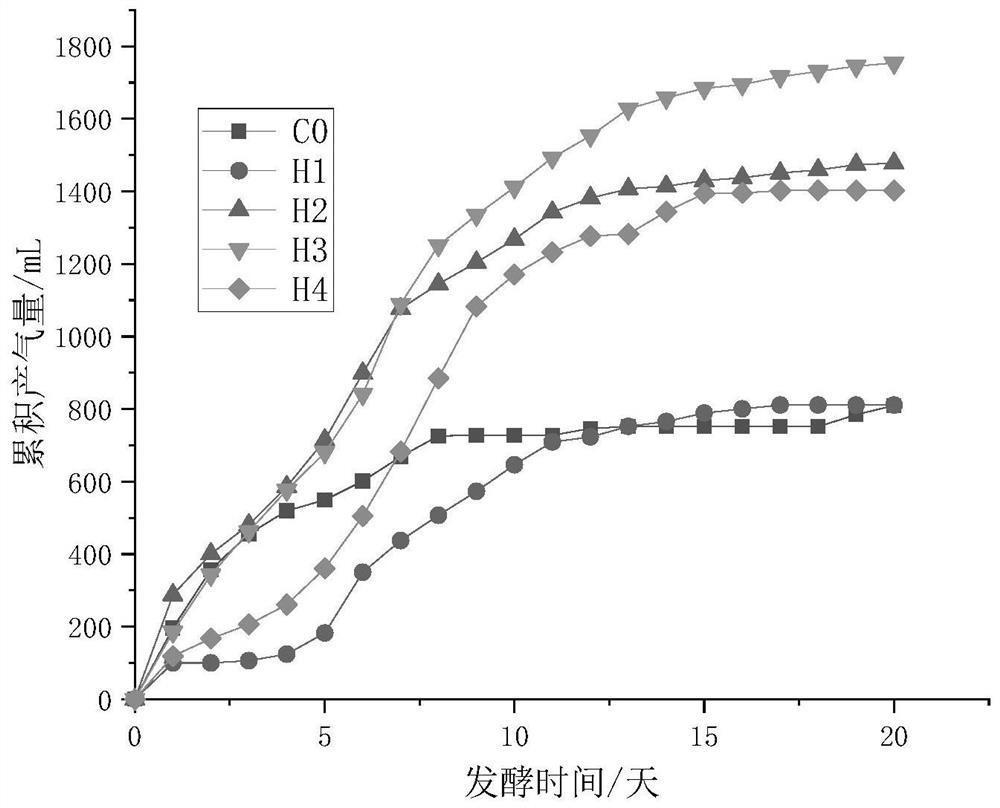

[0062] Anaerobic fermentation was carried out in a 500 mL fermentation bottle. 8 g of pretreated rape straw was added to 240 g of fresh inoculated sludge (TS was 6.67%, VS was 4.71%; the dry mass ratio of rape straw to inoculated sludge was 1:2) and 150mL of distilled water, the total working volume of the fermentation bottle is about 400mL, and the initial pH value is 7.0) During the start-up period, in order to avoid acidification, 1g of sodium bicarbonate was added to provide a buffer, and nitrogen gas was introduced for anaerobic fermentation. The time is 20 days. In order to study the effect of biochar addition on the biogas fermentation potential of rapes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com