Layered cobaltosic oxide material and preparation method and application thereof

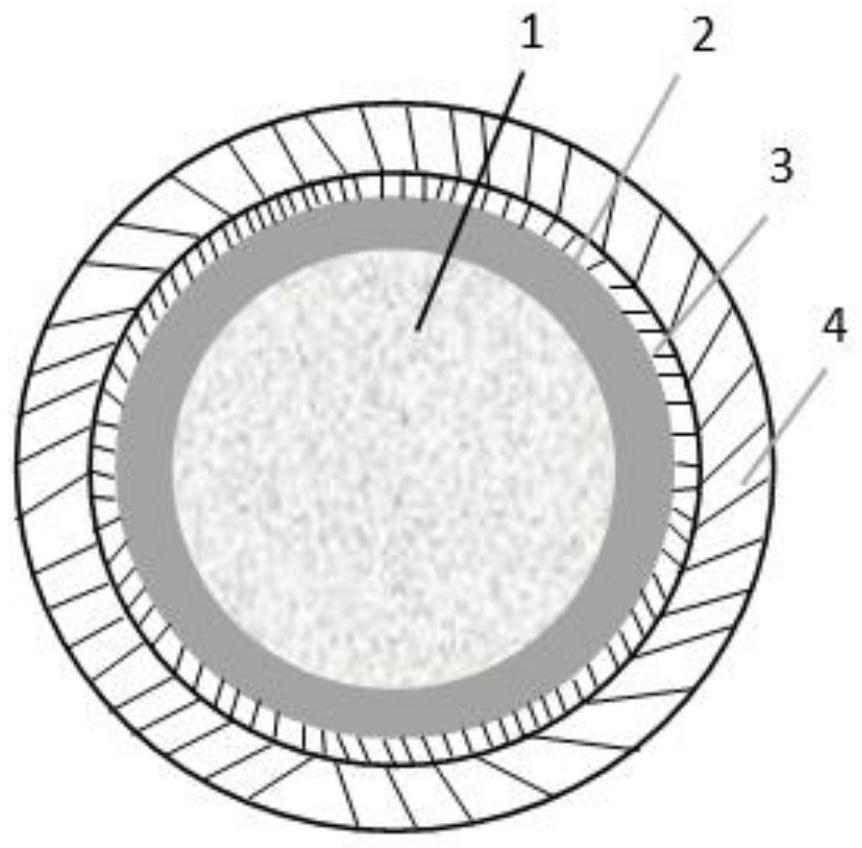

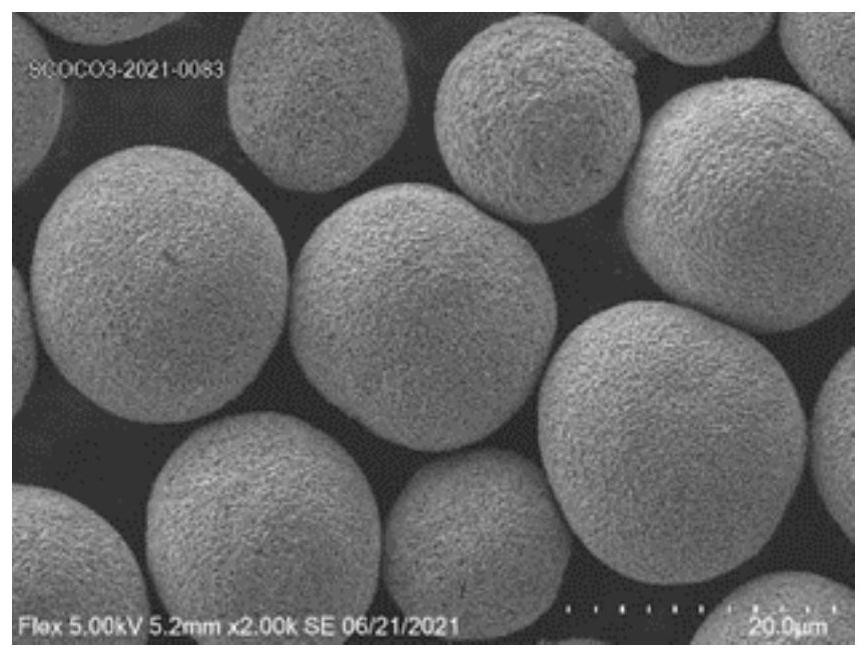

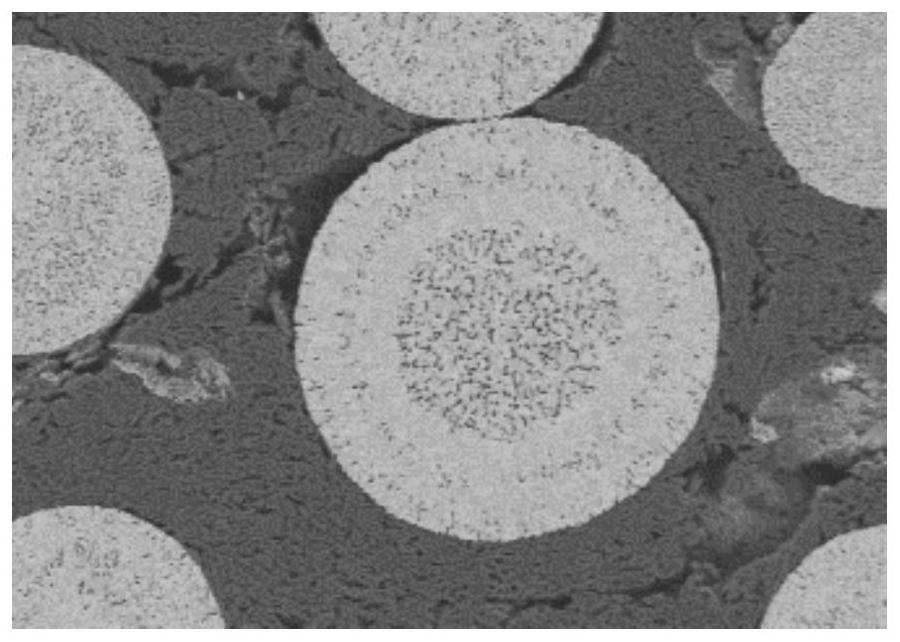

A layered technology of cobalt tetroxide, which is applied in the field of layered cobalt tetroxide material and its preparation, can solve the problems of irregular shape of cobalt trioxide material, which is not conducive to improving the cycle performance of lithium cobalt oxide cathode material, and uneven external structure, so as to improve cycle stability Uniform performance, shape, stable and orderly structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In this embodiment, a method for preparing the layered cobalt tetroxide material is also provided, including the following steps:

[0035] S1: Add water into the reaction kettle as the bottom liquid, and put 200kg of cobalt carbonate as the seed crystal, the seed crystal size is 8-14 μm, adjust the pH to 7.5-8.5; combine the cobalt salt solution, soluble metal salt solution and precipitant solution Flow is added in the reactor, and the feed flow ratio of described cobalt salt solution, precipitant solution and soluble metal salt solution is (10-20):(20-32):1; Wherein, the feed flow rate of initial cobalt salt solution After 5-25 hours, the feed flow rate of the cobalt salt solution is adjusted to 5-25g / L, after 15-40h, the feed flow rate of the cobalt salt solution is adjusted to 65g / L; at the same time, the precipitant solution and the feed flow rate of the soluble metal salt solution are adjusted in proportion;

[0036] S2: Aging, filtering and washing the product ob...

Embodiment 1

[0049] A kind of layered tricobalt tetroxide material, its preparation method comprises the following steps:

[0050] S1: Using deionized water, configure 20g / L aluminum sulfate solution, 100g / L cobalt chloride solution and 130g / L ammonium bicarbonate solution;

[0051] S2: Add 200L deionized water into the reaction system as the bottom liquid, and put 200kg of cobalt carbonate as the seed crystal, the seed crystal size is about 10μm, and adjust the pH to 8.0; then the prepared cobalt chloride solution and ammonium bicarbonate solution And the aluminum sulfate solution is fed into the reaction kettle at the same time by means of co-current feeding, the feed flow ratio of the cobalt chloride solution, the ammonium bicarbonate solution and the aluminum sulfate solution is 12:23.8:1; the temperature of the reaction kettle is 48°C, stirring Speed is 280r / min; The feeding flow rate of cobalt chloride solution increases step by step in the feeding process, and initial cobalt chlor...

Embodiment 2

[0059] A kind of layered tricobalt tetroxide material, its preparation method comprises the following steps:

[0060] S1: Use deionized water, configure 40g / L aluminum nitrate solution, 150g / L cobalt sulfate solution and 180g / L ammonium bicarbonate solution;

[0061] S2: Add 200L of deionized water into the reaction system as the bottom liquid, and put 200kg of cobalt carbonate as the seed crystal, the seed crystal size is about 12 μm, and adjust the pH to 7.5; then the prepared cobalt nitrate solution, ammonium bicarbonate solution and The aluminum sulfate solution is fed into the reactor simultaneously in a co-current feeding manner, and the feed flow ratio of the cobalt sulfate solution, the ammonium bicarbonate solution and the aluminum nitrate solution is 10:22:1; the temperature of the reactor is 50°C, and the stirring rate is 280r / min; the feed flow rate of the cobalt salt solution increases step by step during the feeding process, the initial cobalt flow rate is 30L / h,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com