Shuttle trolley for carrying materials

A shuttle car and car body technology, applied in the field of warehousing and logistics, can solve the problems of increasing the size and weight of the AGV car body, the overall structure of the AGV car body, and the large space of the car body, so as to achieve increased space utilization, simple structure, The effect of volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention. The parts not mentioned in the present invention are all prior art.

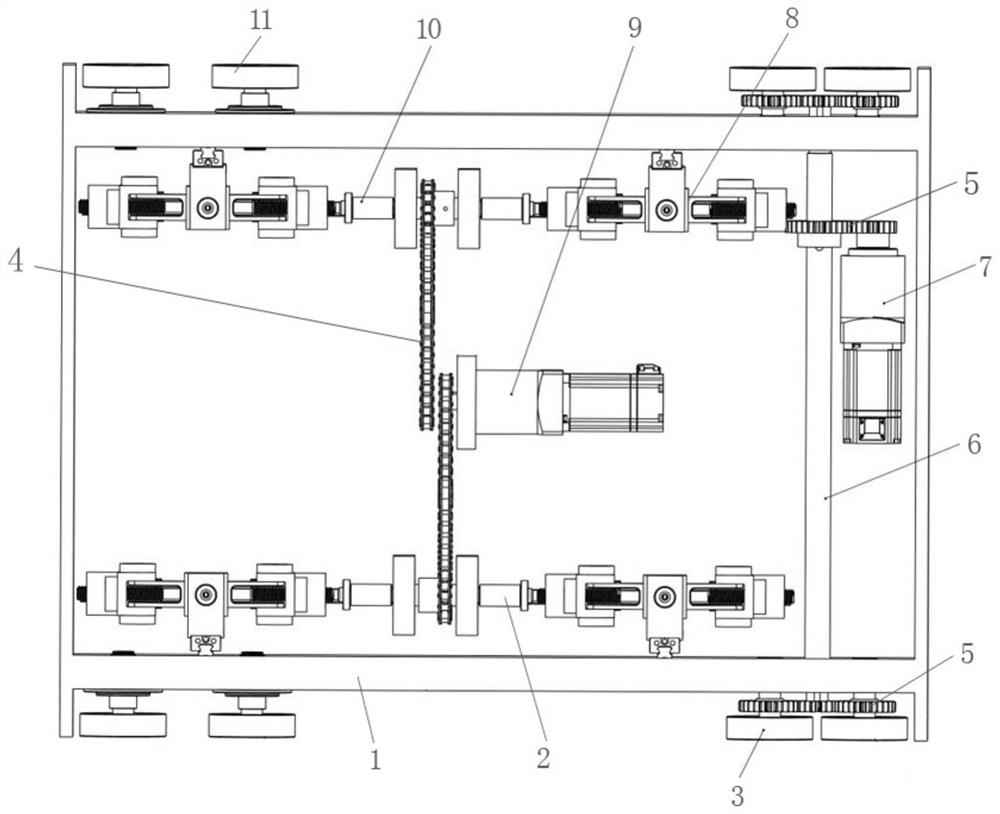

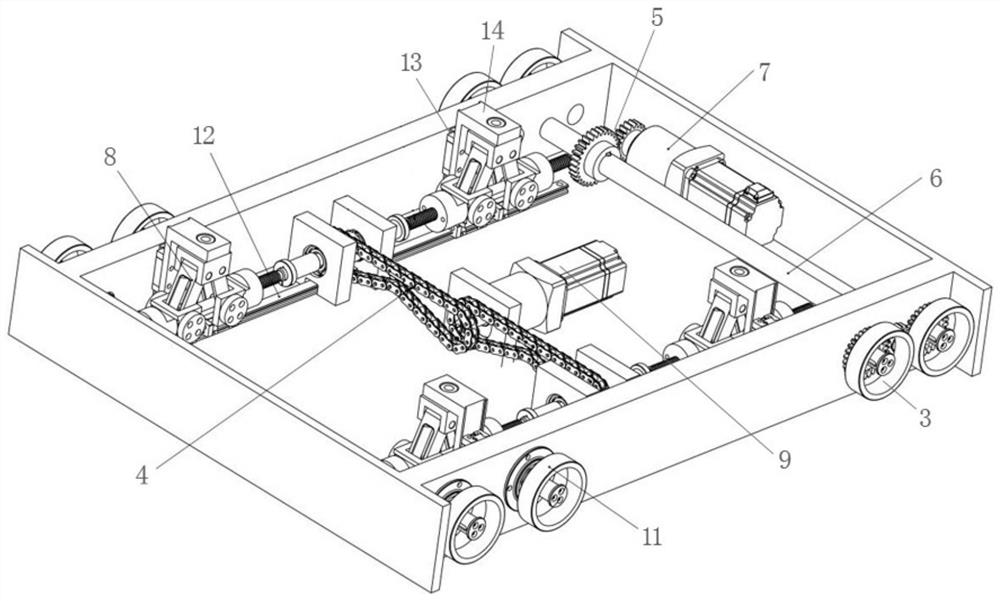

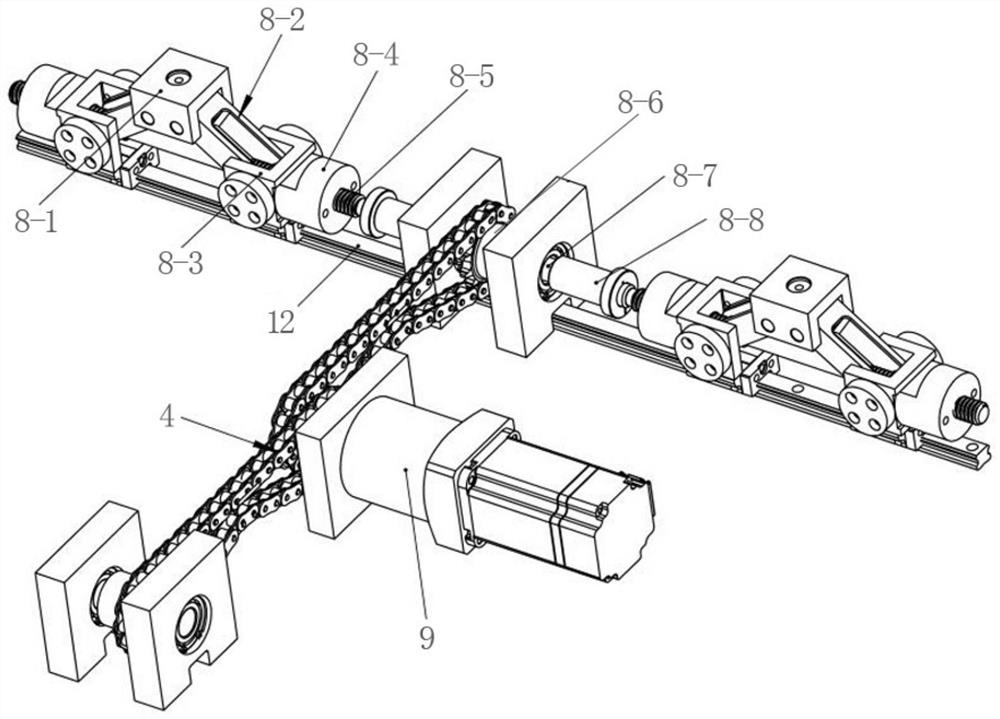

[0018] see Figure 1 to Figure 3 , the present invention provides a shuttle sub-car for carrying materials, including a car body 1, a walking assembly arranged at the bottom of the car body 1, and a cover plate (not shown in the figure) arranged in the car body 1 to cover it ) Jacking mechanism for jacking up or down. The jacking mechanism includes a drive mechanism 9 arranged in the car body 1, slide rails 12 on the left and right sides along the traveling direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com