Adsorbing material as well as preparation method and application thereof

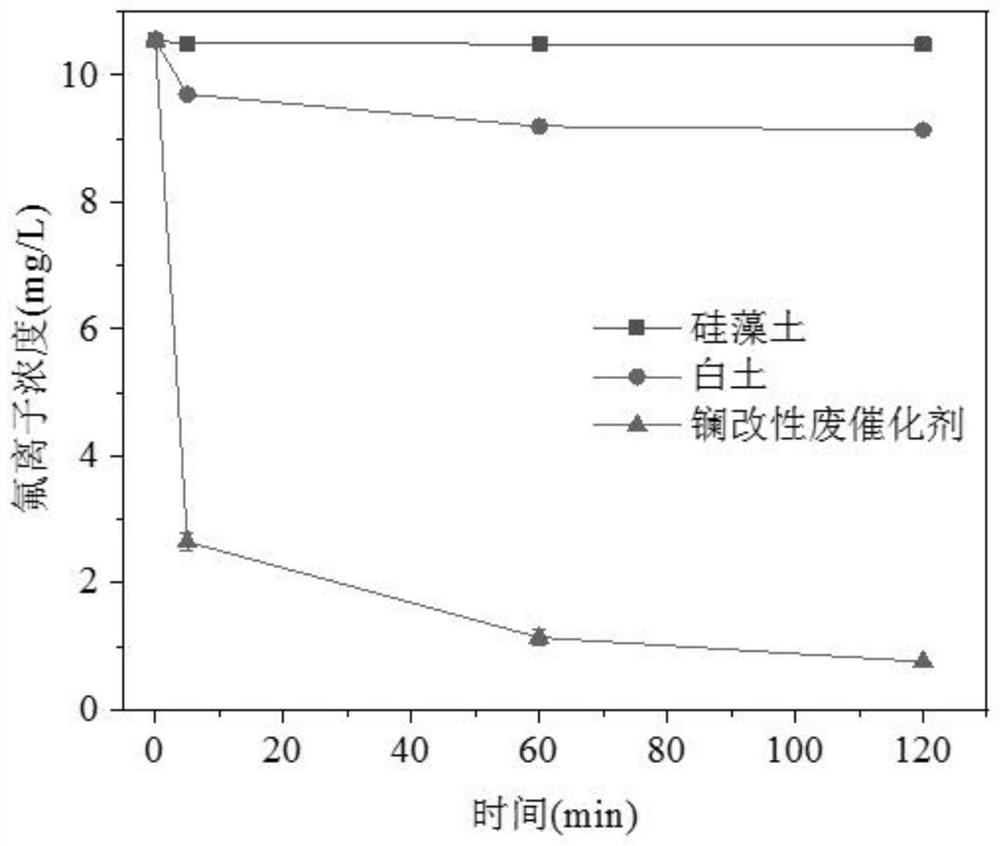

An adsorption material and reaction technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of high cost, high treatment cost, difficult separation of concentrated salts, etc., to reduce adsorption costs, improve The effect of adsorption capacity and operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] According to another aspect of the present invention, the present invention also relates to a method for preparing an adsorbent, comprising the following steps:

[0031] The solid catalyst, soluble lanthanum solution and alkali solution are mixed and subjected to modification reaction to obtain the adsorption material.

[0032] The preparation method of the adsorption material in the present invention is simple, easy to operate, does not require strict preparation conditions, and can prepare an adsorption material with excellent adsorption effect.

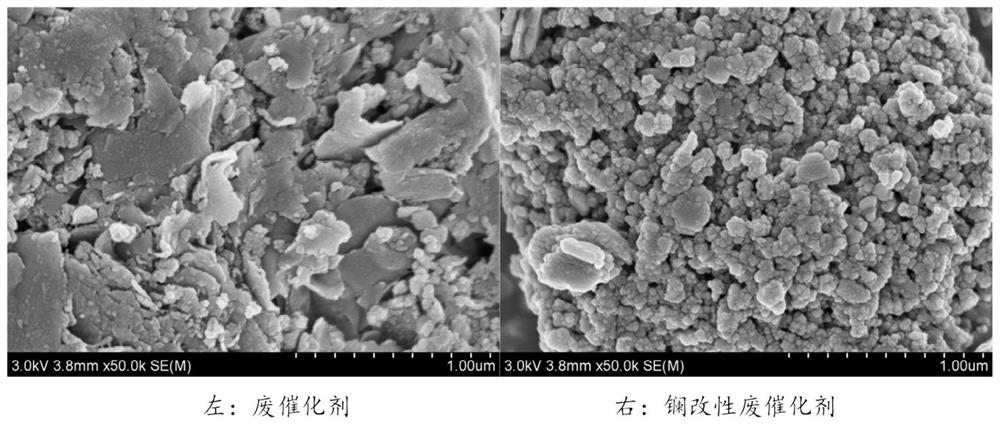

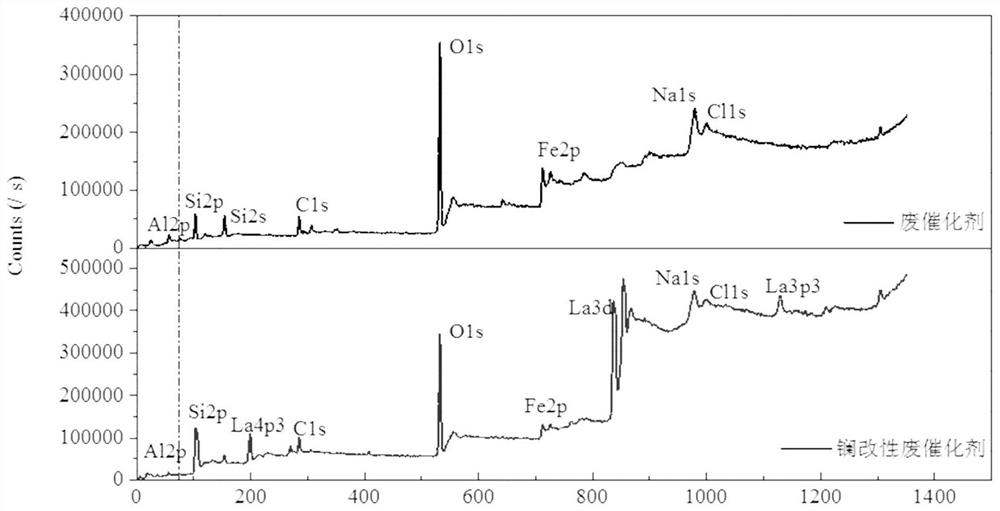

[0033] The present invention utilizes soluble lanthanum solution and alkaline solution to modify the solid catalyst, and adds OH to the solid catalyst - , to dissolve part of the components in the solid catalyst, such as SiO 2 and Al 2 o 3 , making the catalyst surface negatively charged. Lanthanum ions combine with oxygen atoms in the solid catalyst to form La-O bonds through electrostatic attraction and ion exchange. ...

Embodiment 1

[0054] The preparation method of the adsorption material provided in this embodiment comprises the following steps:

[0055] 1. Pass the solid catalyst through a 300-mesh standard sieve, and wash the solid catalyst to neutrality with deionized water;

[0056] 2. Put the solid catalyst into an electric blast drying oven, and dry it at 105°C for later use;

[0057] 3. Prepare 100mL of 0.1mol / L La(NO 3 ) 3 solution, and added to a 250mL round bottom flask;

[0058] 4. Add 2mol / L NaOH solution dropwise to the solution to control the pH to 8.1;

[0059] 5. Add 1.5g of pretreated solid catalyst, and stir on a constant temperature magnetic stirrer, set the rotation speed at 200r / min, the reaction temperature at 40°C, and the stirring time for 9h;

[0060] 6. Put the liquid adsorption material into an electric blast drying oven, dry it at 105° C., wash it until it is neutral, and dry it again for later use to obtain the adsorption material.

Embodiment 2

[0062] The preparation method of the adsorption material provided in this embodiment comprises the following steps:

[0063] 1. Pass the solid catalyst through a 200-mesh standard sieve, and wash the solid catalyst to neutrality with deionized water;

[0064] 2. Put the solid catalyst into an electric blast drying oven, and dry it at 105°C for later use;

[0065] 3. Prepare 100mL of 0.1mol / L La(NO 3 ) 3 solution, and added to a 250mL round bottom flask;

[0066] 4. Add 2mol / L NaOH solution dropwise to the solution to control the pH to 4.4;

[0067] 5. Add 1.5g of pretreated solid catalyst, and stir on a constant temperature magnetic stirrer, set the rotation speed at 200r / min, the reaction temperature at 40°C, and the stirring time for 18h;

[0068] 6. Put the liquid adsorption material into an electric blast drying oven, dry it at 105° C., wash it until it is neutral, and dry it again for later use to obtain the adsorption material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com