Nanoparticle colloid cluster and structure-controllable preparation method based on emulsion method

A nanoparticle and inorganic nanoparticle technology, applied in the field of nanoparticle colloidal cluster materials, can solve the problems of inaccurate control of the spatial configuration of colloidal clusters, high cost of DNA molecules, cumbersome nanoparticle modification process, etc. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] (1) Preparation of oil phase: Synthesize inorganic nanoparticles with uniform size by hydrothermal method or oil thermal method; use functional group-terminated oil-soluble polymers to uniformly modify the surface of inorganic nanoparticles by ligand exchange method; Take the precipitate after centrifugation, and then disperse it in a water-immiscible oil phase organic solvent to obtain an oil phase in which the polymer uniformly modifies inorganic nanoparticles; the rotational speed of the centrifugal precipitation is 5,000-18,000rpm; the centrifugal The precipitation time is 0.2-1h; the concentration of the nanoparticle oil phase is 0.001-1mg / mL;

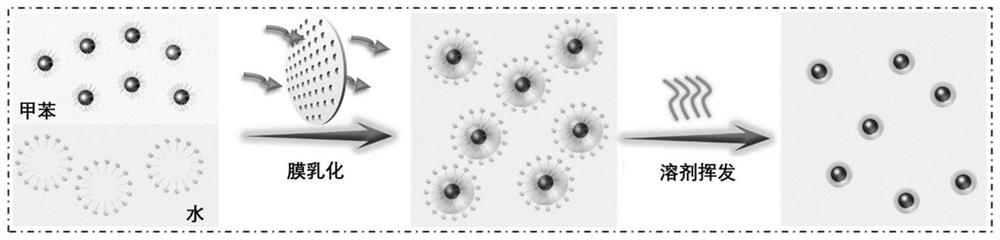

[0040] (2) Preparation of emulsion droplets: the oil phase obtained in step (1) is mixed with the water phase containing surfactant, the mixed solution is added to the membrane emulsification device, and the diameter is obtained by manually extruding back and forth 20-100 times. Uniform oil-in-water emulsion droplets; the mix...

Embodiment 1

[0052] A method for preparing a structure-controllable colloidal nanoparticle cluster based on an emulsion method, specifically comprising the following steps:

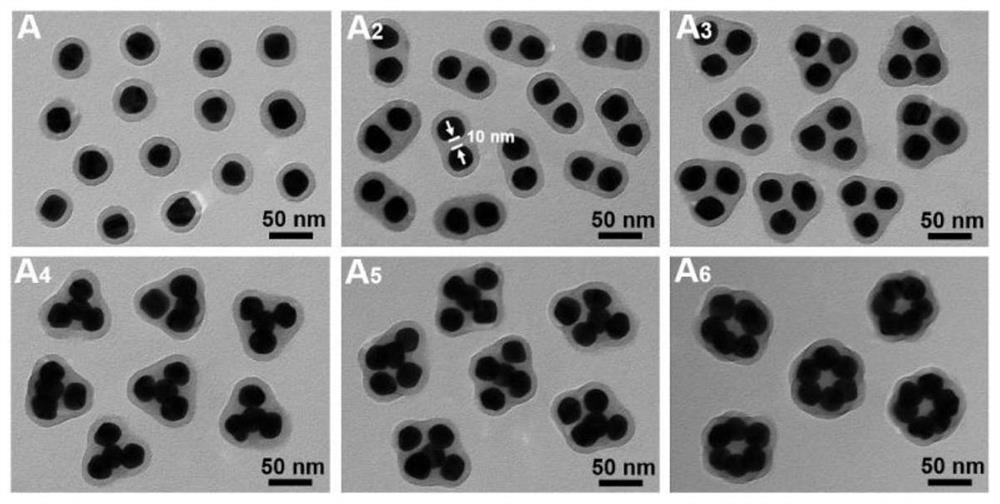

[0053] (1) Preparation of the oil phase: using mercapto-terminated polystyrene with a molecular weight of 12 kDa, the surface of gold nanoparticles with a diameter of 32 nm was uniformly modified by a ligand exchange method. After centrifugation at 10,000rpm for 0.5h, the precipitate was collected, and then dispersed in the in toluene.

[0054] The gold nanoparticles are prepared according to the following method: a sodium citrate aqueous solution with a concentration of 30 mg / mL and an aqueous chloroauric acid solution with a concentration of 10 mg / mL are prepared, and 1 mL of the above-mentioned chloroauric acid solution is added to 100 mL of ultrapure water, heated to boiling , followed by adding 1 mL of the above sodium citrate solution and reacting at 100° C. for 30 minutes. Then the temperature was lowered to ...

Embodiment 2

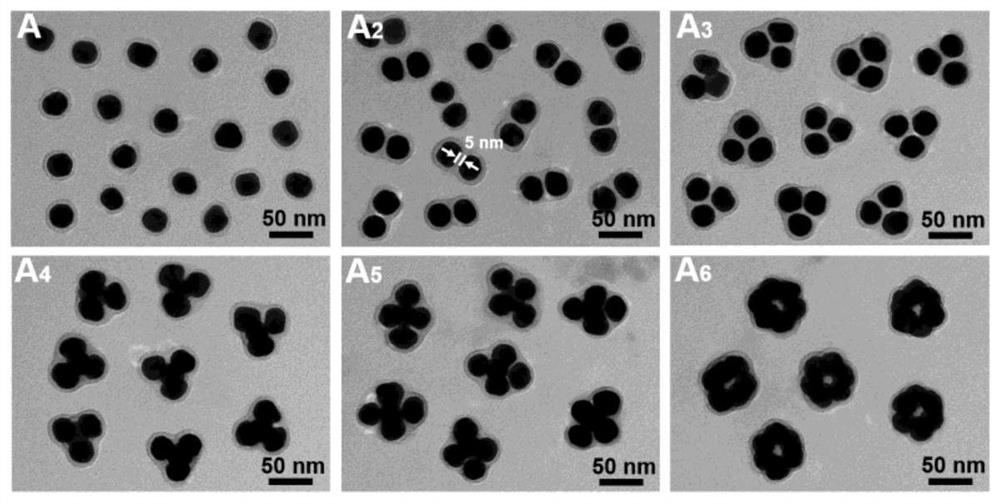

[0059] A method for preparing a structure-controllable colloidal nanoparticle cluster based on an emulsion method, specifically comprising the following steps:

[0060] (1) Preparation of the oil phase: using mercapto-terminated polystyrene with a molecular weight of 5 kDa, the surface of gold nanoparticles with a diameter of 32 nm was uniformly modified by a ligand exchange method. After centrifugation at 10,000rpm for 0.5h, the precipitate was collected, and then dispersed in the in toluene.

[0061] (2) Preparation of emulsion droplets: cetyltrimethylammonium bromide was dissolved in water at a concentration of 1 mg / mL, and 100 μL of the above oil phase with different concentrations were mixed with 1 mL of the above water phase. Add the mixed solution to the membrane emulsification device ( figure 1 ), the pore size of the filter membrane of the emulsification device was 0.5 μm, and the oil-in-water emulsion droplets with a diameter of 2 μm and uniform diameter were obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com