Low-GI oat biscuit preparation device and method

A technology for oatmeal biscuits and preparation devices, which is applied in chemical instruments and methods, mixers with rotating stirring devices, transportation and packaging, etc., can solve the problems of poor mixing effect and affecting the quality of oatmeal biscuits, so as to avoid stratification, Improve the mixing effect and improve the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

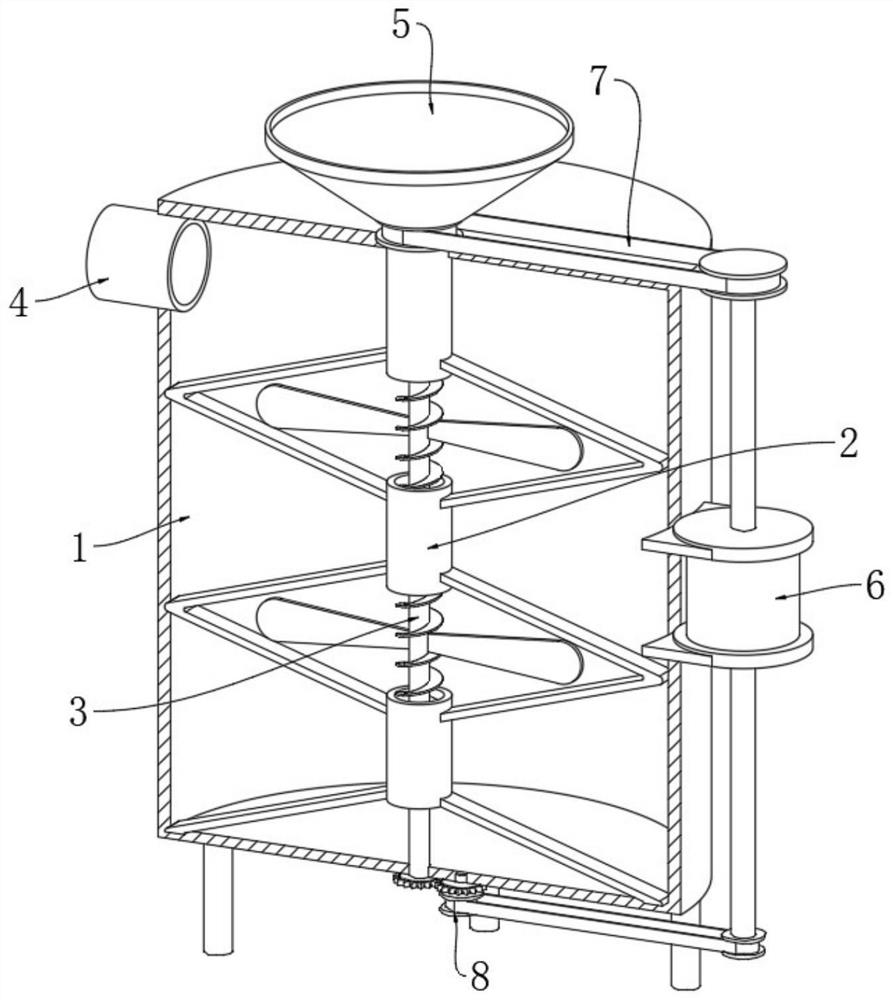

[0034] see figure 1 As shown, a low GI oatmeal biscuit preparation device described in this embodiment is different from the prior art in that we set a first stirring mechanism 2 and a second stirring mechanism 3 in the inner cavity of the mixing cylinder 1. The outer side of the barrel 1 is fixed with a double-head motor 6, the top of the mixing barrel 1 is provided with a forward drive assembly 7, and the bottom of the mixing barrel 1 is provided with a reverse drive assembly 8; the double-head motor 6 passes through the forward drive assembly 7 And the reverse drive assembly 8 simultaneously drives the first stirring mechanism 2 and the second stirring mechanism 3 to rotate in the opposite direction. After the main material and auxiliary materials are put into the mixing drum 1, the first stirring mechanism 2 and the second stirring mechanism 3 The main material and auxiliary materials are mixed in two directions, and the mixing effect is good;

Embodiment 2

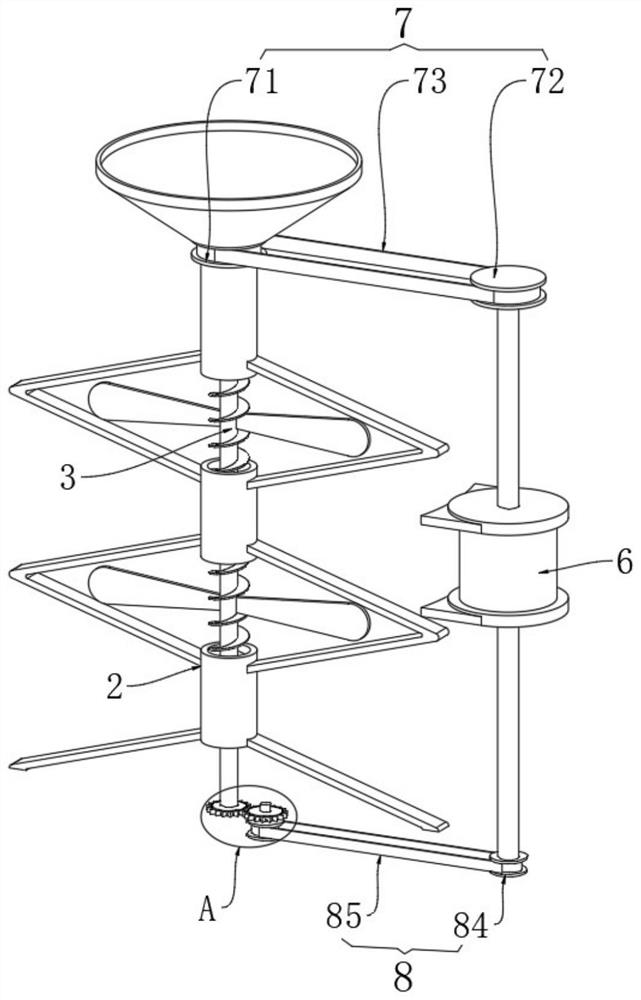

[0036] see Figure 4As shown, in order to enable the first stirring mechanism 2 and the second stirring mechanism 3 to realize the function of turning the raw materials up and down during the rotation process, we need to make the first stirring mechanism 2 and the second stirring mechanism 3 cooperate with each other, so for the second The structures of the first stirring mechanism 2 and the second stirring mechanism 3 are specifically refined, and the structures of the refined first stirring mechanism 2 and the second stirring mechanism 3 are as follows:

[0037] The first stirring mechanism 2 comprises a first sleeve pipe 21, a second sleeve pipe 22, a third sleeve pipe 23 and a stirring frame 24, wherein the stirring frame 24 is set to two, and the first sleeve pipe 21 and the second sleeve pipe 22 are stirred The frame 24 is fixed, the second sleeve 22 and the third sleeve 23 are fixed by the stirring frame 24, the first sleeve 21 is flexibly connected with the top wall of...

Embodiment 3

[0041] We assume that the first casing 21 in embodiment 2 drives the stirring frame 24 to rotate clockwise, and the shaft rod 31 drives the auger 32 to rotate counterclockwise to realize the purpose of quickly mixing the added auxiliary materials to the bottom of the main material, so if the first set The tube 21 drives the agitating frame 24 to rotate counterclockwise, and the shaft 31 drives the auger 32 to rotate clockwise, so that the auger located inside the first casing 21, the second casing 22 and the third casing 23 can be agitated. The upper section, the middle section and the lower section of 32 transmit the mixing raw materials upwards sequentially to achieve the purpose of turning the raw materials, further improve the mixing effect, avoid stratification, and help improve the quality of oatmeal biscuits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com