Brush carrier structure for alternator

A technology of alternators and brush holders, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of reducing the wear resistance of carbon brushes, affecting the conductivity of carbon brushes, and affecting carbon brushes, etc., to achieve airtightness and Good scalability, simple structure, and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

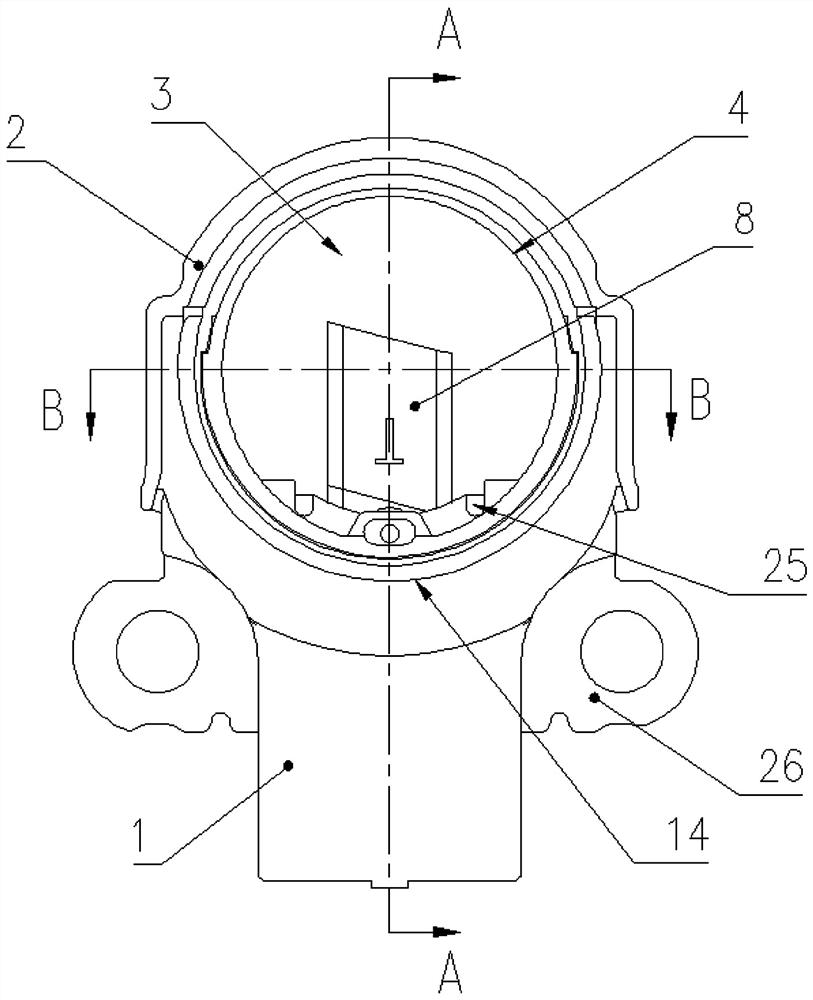

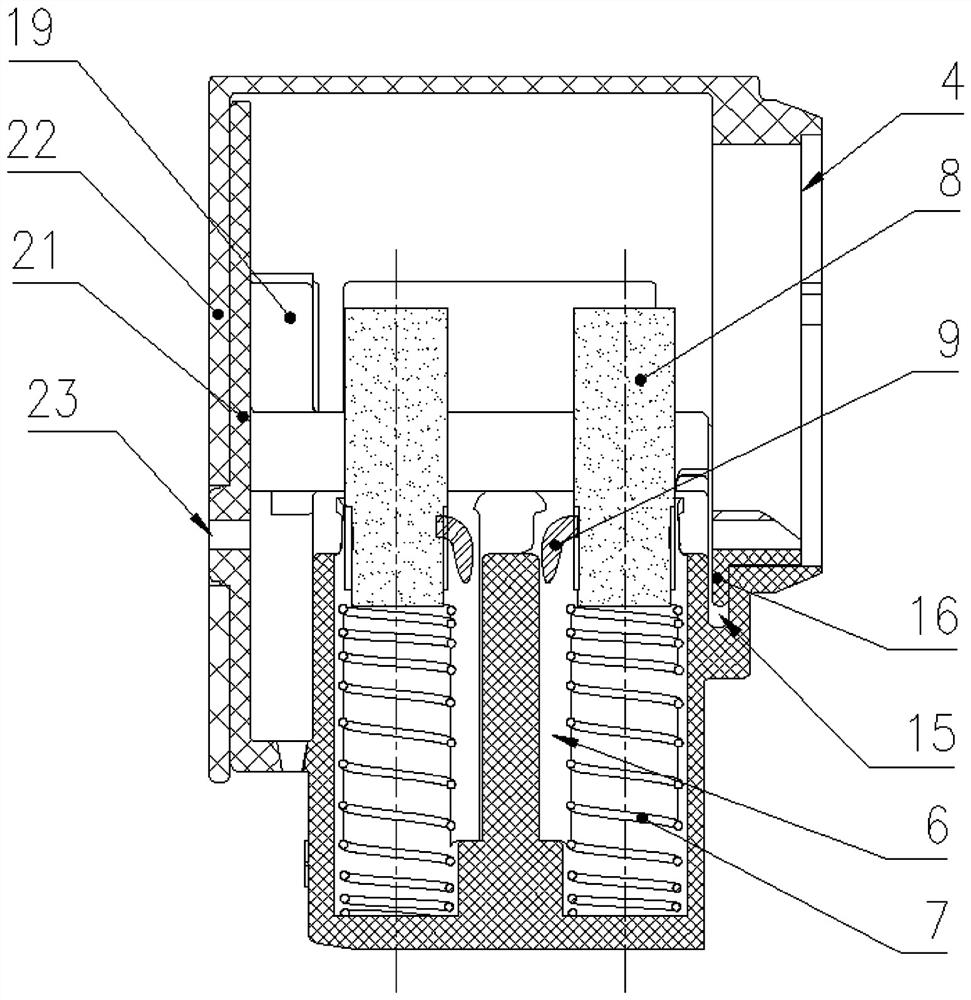

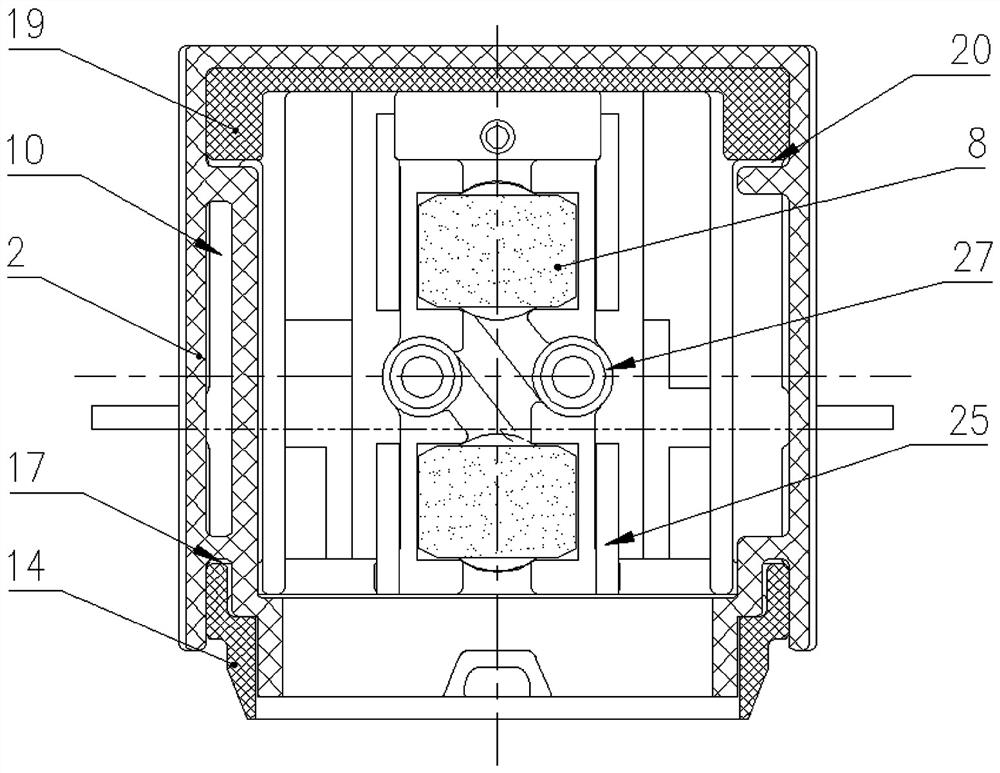

[0026] see Figure 1 to Figure 7 , a brush holder structure for an alternator, comprising a brush holder body 1 and a carbon brush protection cover 2. The upper end of the brush holder body 1 is provided with a cavity 3, the upper end and the front end of the cavity 3 are open, the carbon brush protection cover 2 is covered on the upper end of the brush holder body 1, and the front end of the carbon brush protection cover 2 is arranged The cylinder 4 corresponds to the opening of the front end of the concave cavity 3, and the cylinder 4 is used for inserting the slip ring of the alternator. The rear end of the brush holder body 1 is provided with a first baffle plate 21 extending upward, so that The rear end of the carbon brush protection cover 2 is provided with a second baffle plate 22 extending downward, and the carbon brush protection cover 2 is covered on the brush holder body 1, so that the first baffle plate 21 is located inside the second baffle plate 22, and the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com