Contact piece and micro-rectangular electric connector using same

A technology of electrical connectors and contacts, which is applied to contact parts, devices for joining/disconnecting parts, two-part connection devices, etc., can solve problems such as low production efficiency, quality problems, and easy falling off, and achieve good protection Functionality, improved stability, usage time and lifespan increase effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

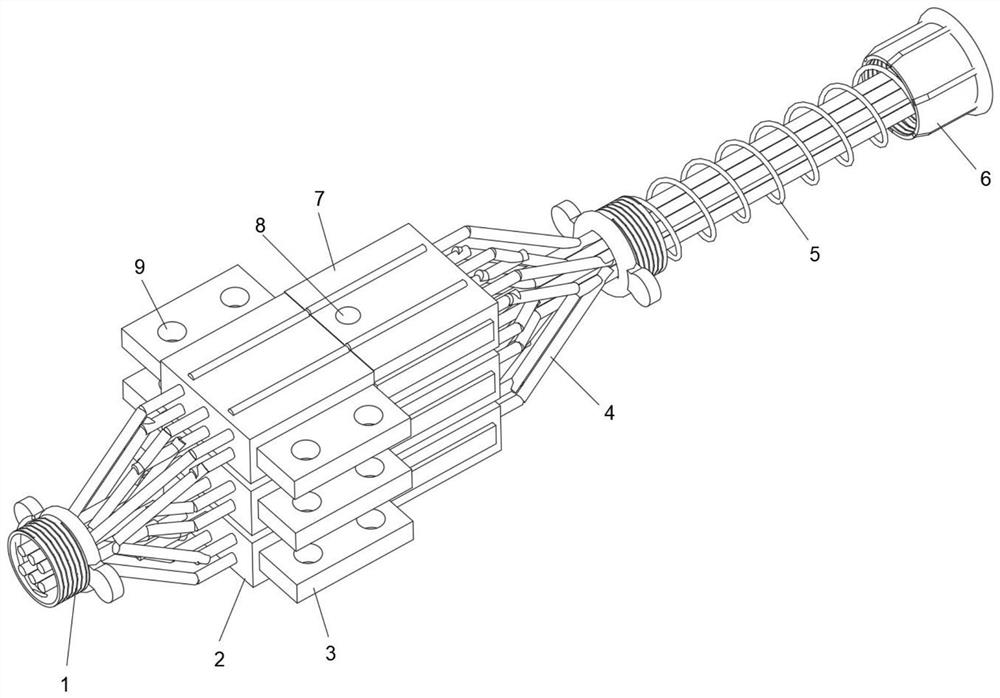

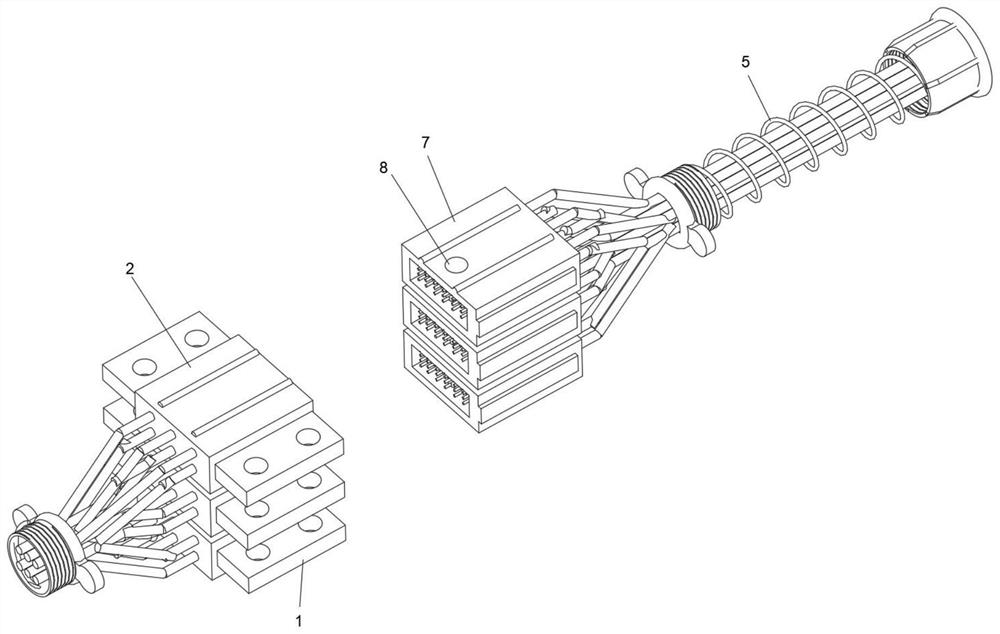

[0044] see Figure 1-3 and Figure 5-9 , an embodiment provided by the present invention: a contact and a micro-rectangular electrical connector using the contact, including a first cluster terminal 1, a socket 2, a fixed mounting plate 3, a connecting wire 4, a protective cover 5, a wiring end 6, plug 7, threaded hole 8 and fixed installation hole 9, the fixed installation plate 3 is symmetrically fixedly connected to both sides of the socket 2, the fixed installation hole 9 is symmetrically opened on the fixed installation plate 3, and the first cluster end 1 is fixed Connected to the inside of the front end of the socket 2, the plug 7 is fixedly plugged on the socket 2, the threaded hole 8 is opened on the upper end of the front part of the plug 7, the connecting wire 4 is fixedly plugged inside the end of the plug 7, and the protective cover 5 is installed on the connecting wire 4, and the front end of the protective cover 5 is fixedly connected to the plug 7, and the ter...

Embodiment 2

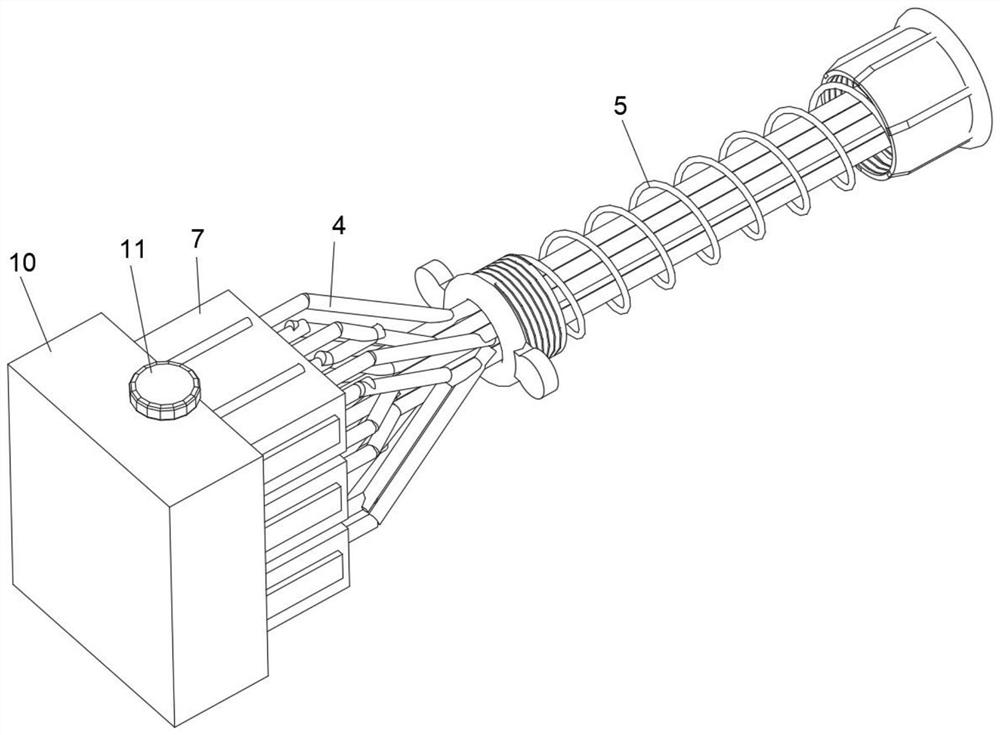

[0057] On the basis of Example 1, such as Figure 4 and Figure 10 As shown, a sealing sliding plate 19 is slidably installed inside the front end of the protective cover 10 , and a pull handle 18 is fixedly installed in the middle of the outer end of the sealing sliding plate 19 .

[0058] When implementing this embodiment, since the front end of the protective cover 10 is slidably installed with a sealing sliding plate 19, the outer middle part of the sealing sliding plate 19 is fixedly equipped with a pull-out handle 18, so that the sealing sliding plate 19 can be moved by pulling the handle 18. It is pulled out from the inside of the protective cover 10 so that the protective cover 10 can protect the plug 7 and the plug 7 can be used without removing the protective cover 10 .

[0059] Working principle: The plug 7 can be securely connected to the protective cover 10 through the insertion column 20 and the spring pin 29, and because the front end of the spring pin 29 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com