Engine water pump impeller modeling method

A technology of water pump impeller and modeling method, which is applied in the direction of engine components, engine cooling, machine/engine, etc., and can solve problems such as inability to modify parameters and low development efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

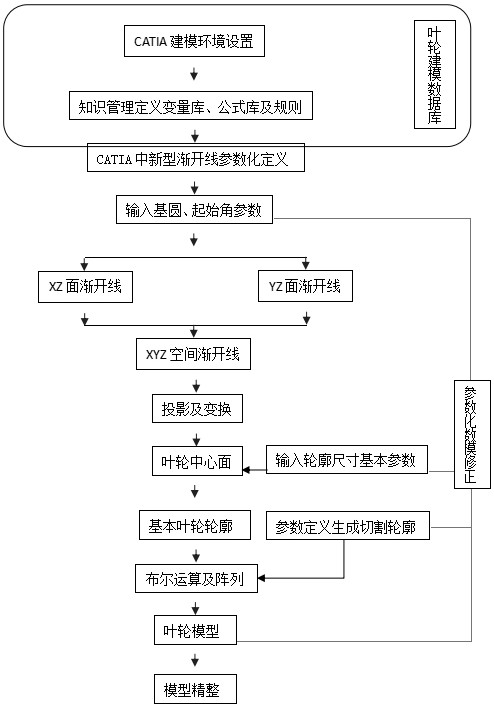

[0044] Such as figure 1 As shown, the engine water pump impeller modeling method of the present invention is designed to solve the problem that the existing three-dimensional model of the engine water pump impeller is almost obtained from the reverse of the physical model.

[0045] Specific steps are as follows:

[0046] 1.CATIA modeling environment setting

[0047] Tool Options General;

[0048] Parameters and measurements: parameter tree view, check with value and with formula;

[0049] Part basic structure: display all in the structure tree;

[0050] 2. Formula and rule definition

[0051] Use f(x) and fog in knowledge engineering to define the parameters of the involute and the rules of the curve;

[0052] Define impeller parameter library: r, n, θ, a

[0053] (where r is the base circle of the involute; n is the number of involute coils, 1 is enough; θ is the starting angle of the involute; a is the radian value of the starting angle; PI is the constant π; 0<=t<1 )...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com