A Modeling Method for Track Data of Rearview Mirror Knob

A technology of track data and modeling method, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problem of low efficiency in the track modeling of rearview mirror knobs, and achieve the problem of torque uncertainty and variable parameters. The effect of adjusting and reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

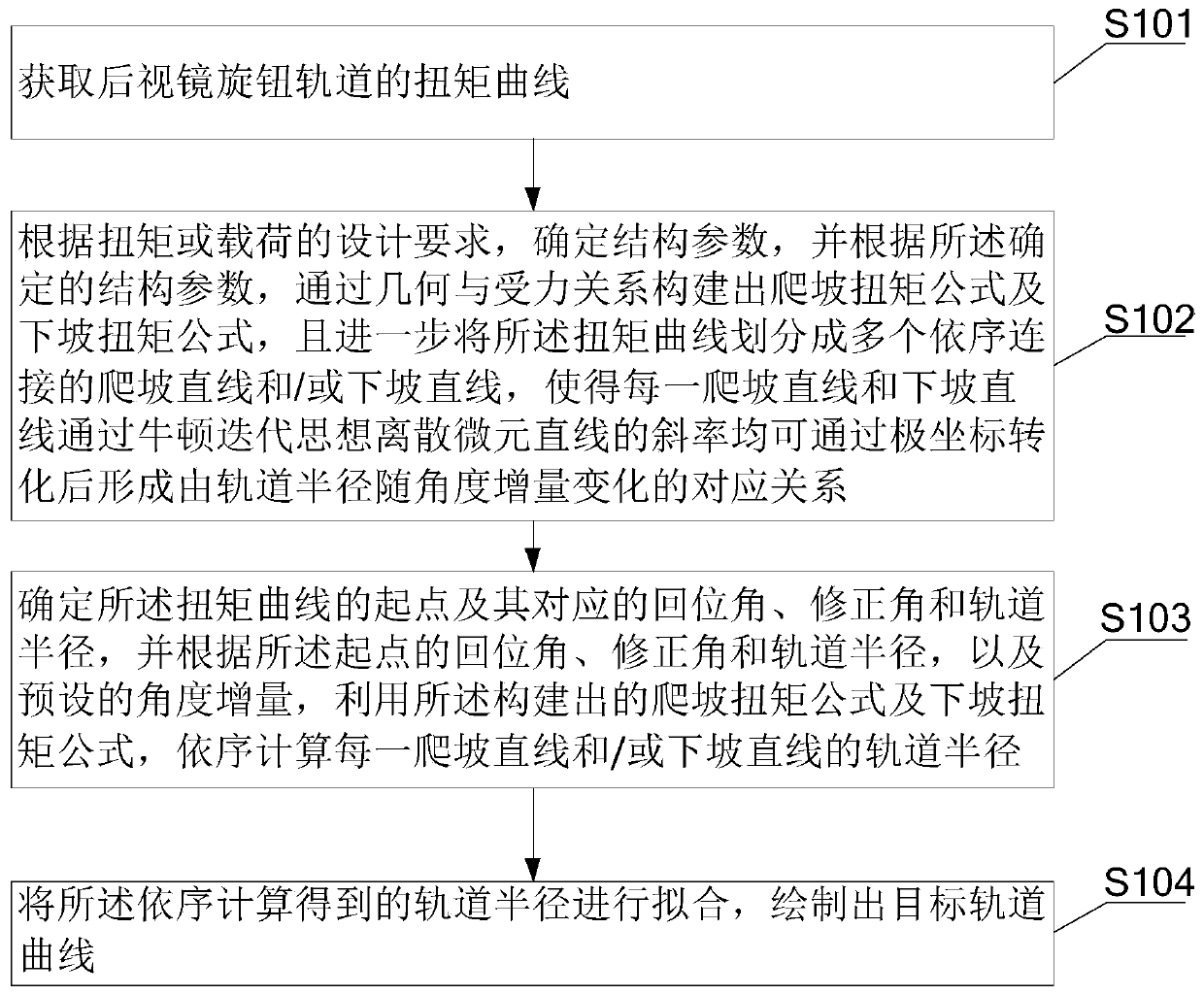

[0034] Such as figure 1 As shown, in an embodiment of the present invention, a rearview mirror knob track data modeling method provided, the method includes:

[0035] Step S101, obtaining the torque curve of the rearview mirror knob track;

[0036] The specific process is that the torque curve is preset, and the obtained torque curve can be discretely processed in the subsequent processing.

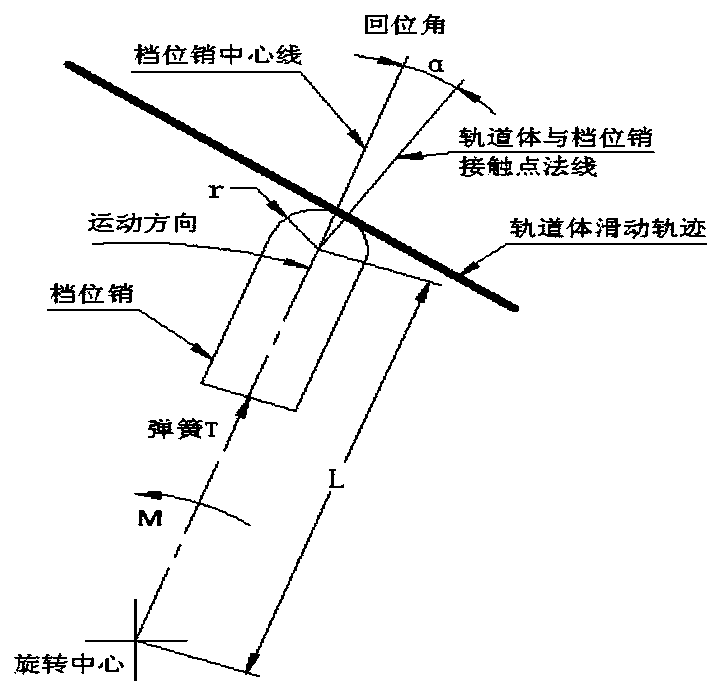

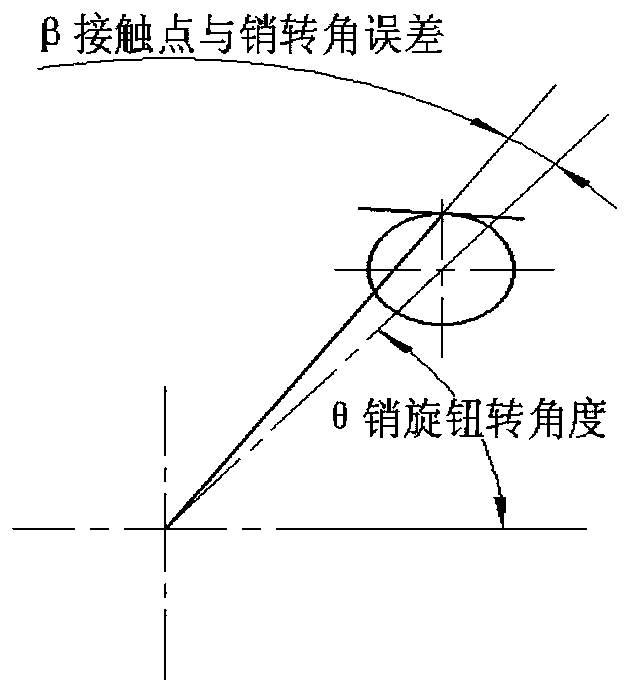

[0037] Step S102, according to the design requirements of torque or load, determine the structural parameters, and according to the determined structural parameters, construct the climbing torque formula and the downhill torque formula through the relationship between geometry and force, and further divide the torque curve A plurality of climbing straight lines and / or downh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com