A Finite Element Accurate Modeling Method for Large Turbine Generator Stator Bars

A technology for turbogenerators and stator bars, which is applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of inconsistent structure of actual bars, time-consuming and laborious modification, easy confusion of models, etc., to achieve omission 3D solid modeling, easy loading, and reduced modeling workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

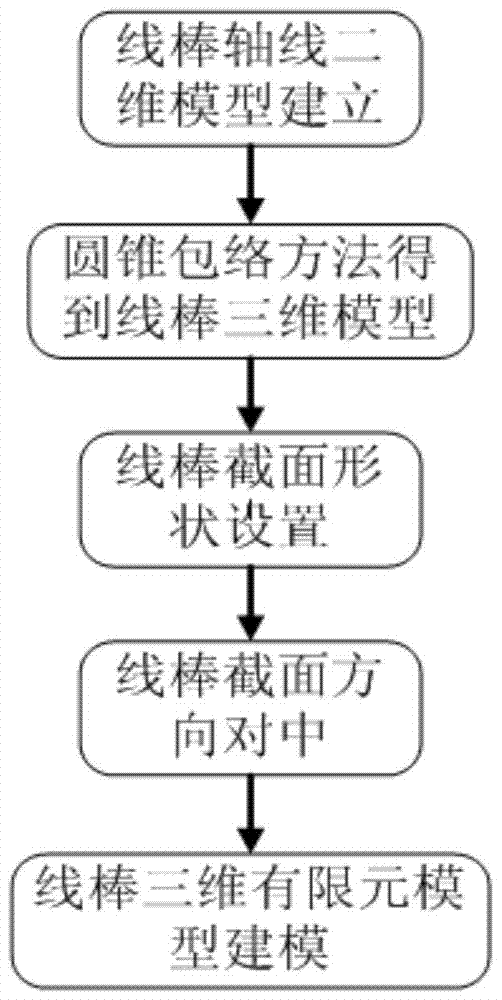

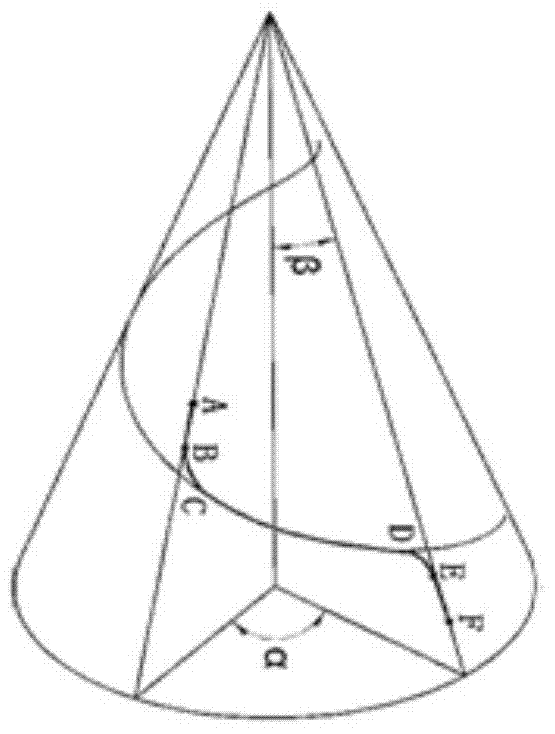

[0028] See Figure 1-10 As shown, a finite element accurate modeling method of a large turbogenerator stator bar is characterized in that the steps of the method are:

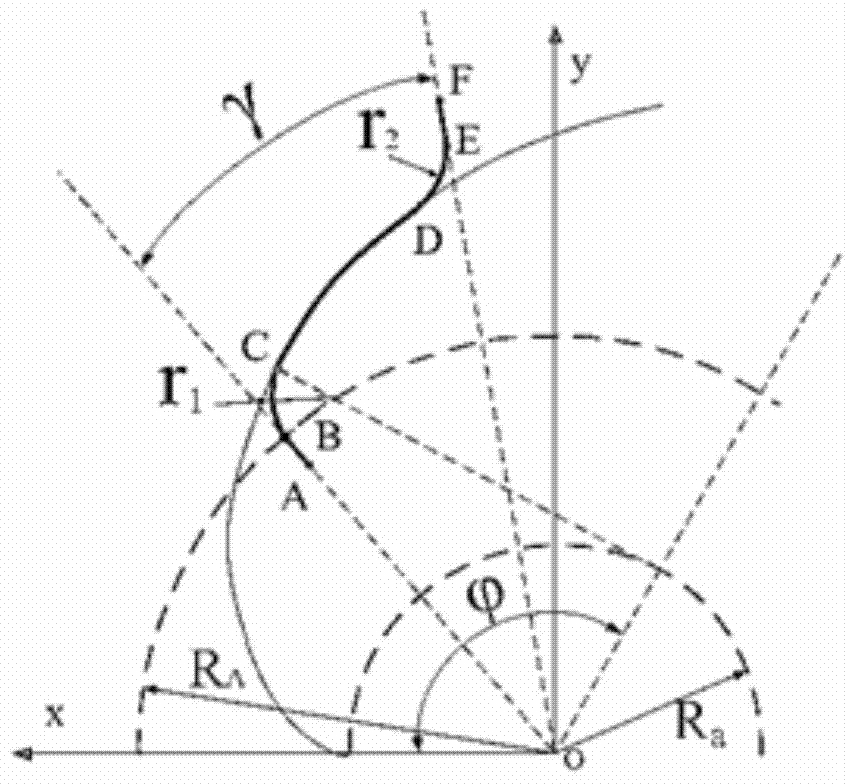

[0029] Step 1: According to the size requirements of the drawing, establish a conic curve plane expansion diagram, and obtain the basic parameters: base circle radius R a , the starting radius R of the starting arc A , starting and ending arc radius r 1 、r 2 , the central angle φ corresponding to the starting point of the involute, and the span angle γ of the expansion line; at the same time, the plane expansion curve is discretized into a series of points and their coordinates are saved (such as Figure 5 shown), and then generate the corresponding key points in the finite element software ANSYS; then use the spline command to connect the above key points, and establish the conic involute, transitional arc and end straight segment of the line bar axis to obtain the line bar A two-dimensional model of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com