Multi-mode flow adjusting system and method based on displacement flow double closed loops

A flow regulation and multi-mode technology, applied in the direction of control/regulation system, flow control, flow control of electrical devices, etc., can solve the problems of low reliability and slow adjustment speed of single feedback loop, and achieve reliability and fault tolerance capability, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

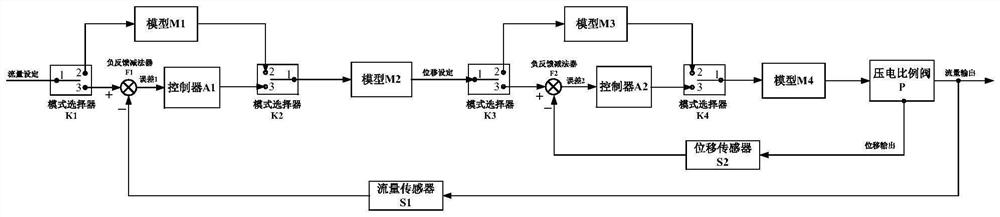

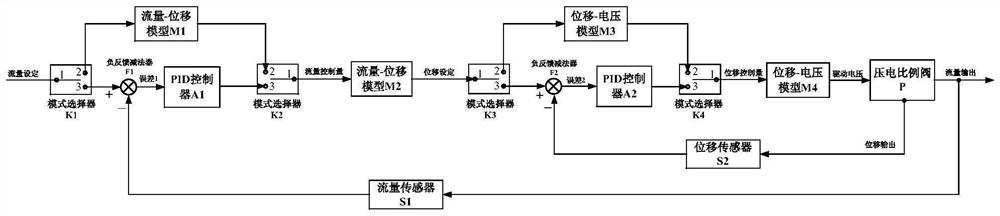

[0037] Such as figure 1As shown, the present invention is a multi-mode flow regulation system based on displacement flow double closed loop, mode selector K1, negative feedback subtractor F1, controller A1, model M1, flow sensor S1, mode selector K2, model M2, mode Selector K3, Negative Feedback Subtractor F2, Model M3, Controller A2, Displacement Sensor S2, Mode Selector K4, Model M4, Piezoelectric Proportional Valve P; Explain Model X

[0038] For controller A1 or A2: the expression of its input-output relationship is as follows:

[0039] u(k)=K p [e(k)-e(k-1)]+K i e(k)+K d (1-a)[e(k)-2e(k-1)+e(k-2)]+(1+a)u(k-1)-au(k-2)

[0040] Among them, the controller input is the output of the negative feedback subtractor F1 or F2, namely the error.

[0041] e(k) is the current error, e(k-1) is the previous historical error, and e(k-2) is the last historical error. u(k) is the current output value of the controller, u(k-1) is the last output value of the controller, u(k-2) is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com