Wafer test equipment

A technology of wafer testing and equipment, applied in the field of wafer testing equipment, can solve problems such as inability to realize continuous operation, affect test efficiency, and affect test results, so as to avoid clamping damage, protect wafers, and ensure accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

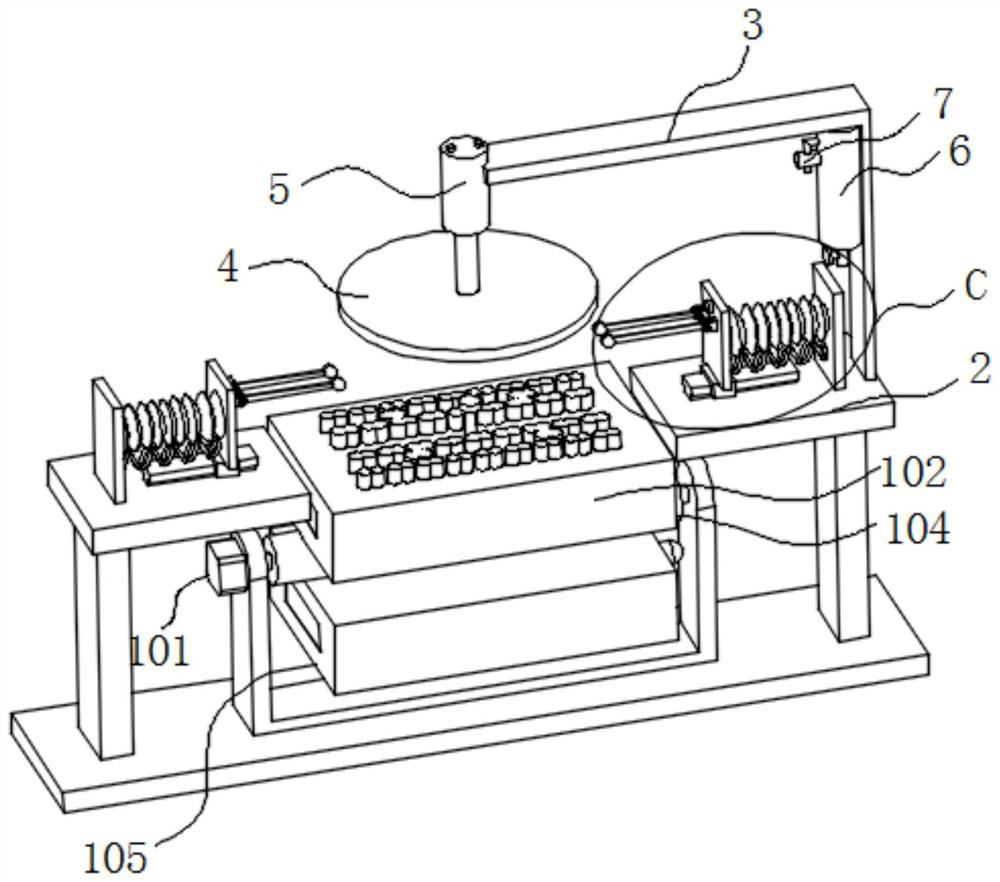

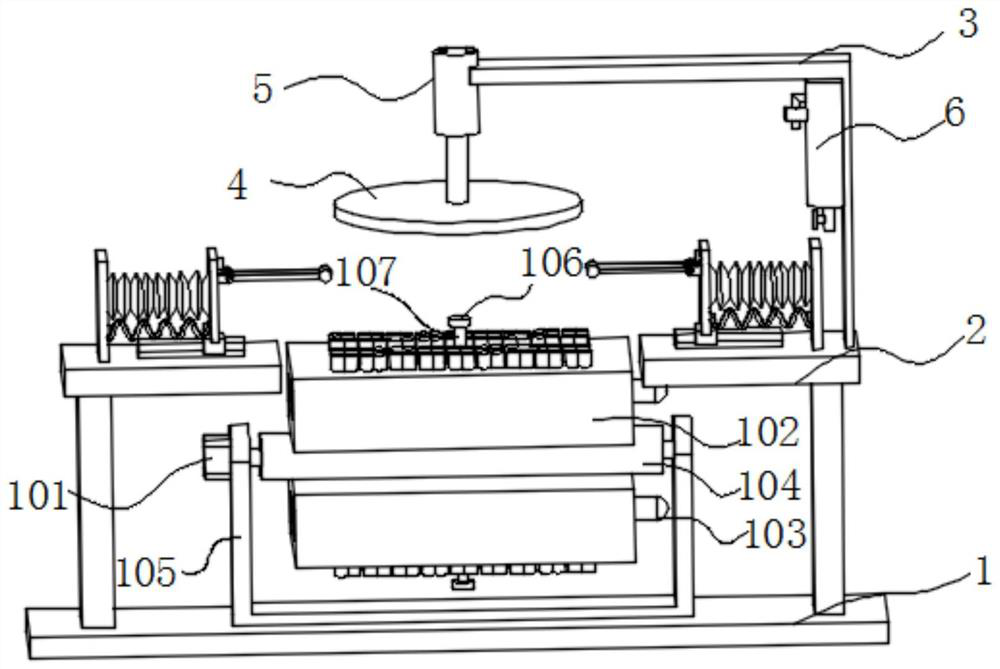

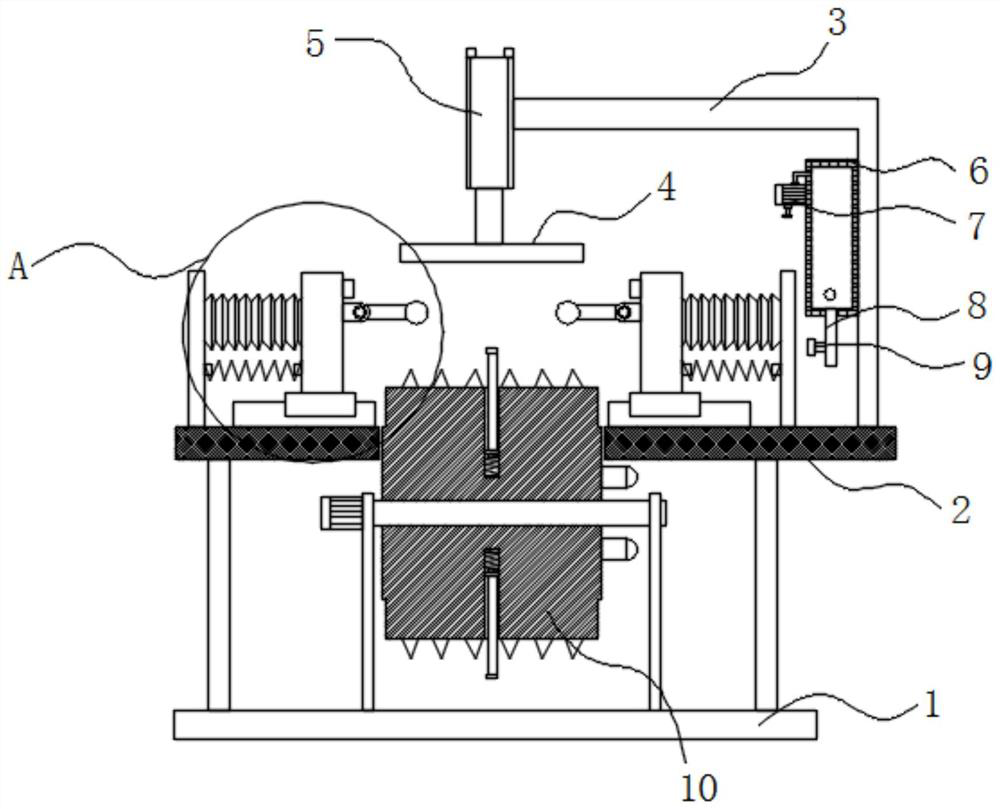

[0033] Such as Figure 1 to Figure 7As shown, a wafer testing device according to the present invention includes a base 1, a mounting plate 2, a mounting frame 3, a rubber backing plate 4, a cylinder 5, an air storage tank 6, an air pump 7, an air release pipe 8, and a solenoid valve 9 , overturning structure 10, overturning motor 101, probe plate 102, warning light 103, rotating shaft 104, support frame 105, gasket 106, movable rod 107, first conductive plate 108, second conductive plate 109, limit cap 110 , the first spring 111, the guide rail 201, the slide button 202, the second spring 203, the baffle plate 204, the air bag 205, the trigger button 206, the rubber ball 207, the swing seat 208, the supporting plate 209, and the mounting plate 2 is erected above the base 1, A support frame 105 is installed on the base 1, and a rotating shaft 104 is mounted on the support frame 105 through a bearing. A turning motor 101 is installed on one side of the supporting frame 105, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com