UHPC fabricated soil nailing wall structure and construction method

A soil-nailed wall and prefabricated technology, which is used in infrastructure engineering, excavation, sheet pile walls, etc., can solve the problems of dust pollution on the construction site, inconvenient equipment use, and difficult to apply to support engineering, etc., to facilitate transportation and hoisting. , Simple and efficient structure, safe and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

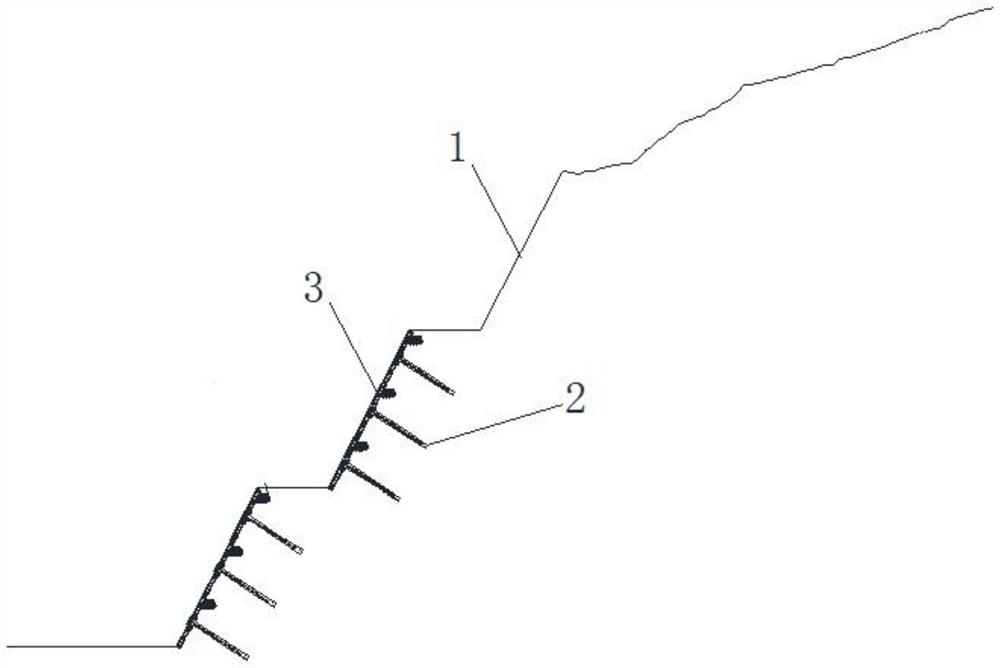

[0038] The invention provides a UHPC assembled soil nail wall structure and construction method, comprising a soil nail anchor rod 2 arranged on a slope surface 1 and a UHPC prefabricated panel 3 arranged on the slope surface 1 .

[0039] The soil nail anchor rods 2 are arranged in rows and columns according to the height of the slope. The soil nail anchor 2 is formed after grouting of steel bars, and comprises steel bars 7 and a grouting body 8. The cement slurry used for the grouting body 8 includes cement, fine aggregate, water reducing agent, water and expansion agent.

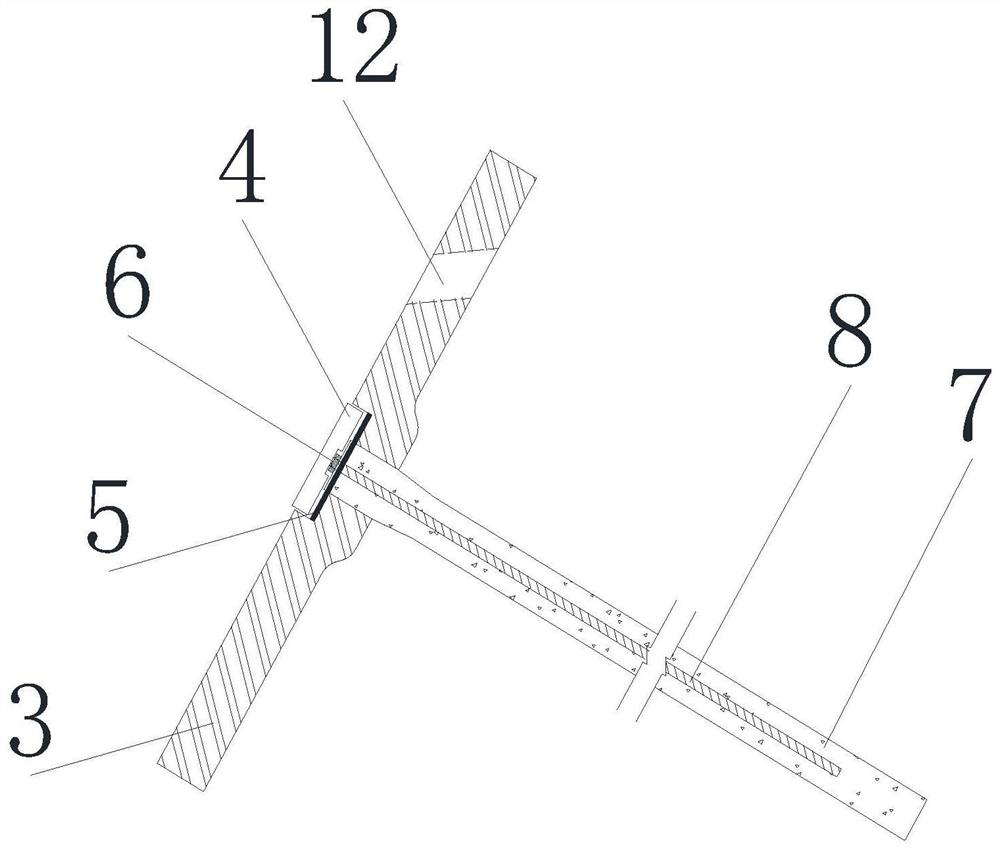

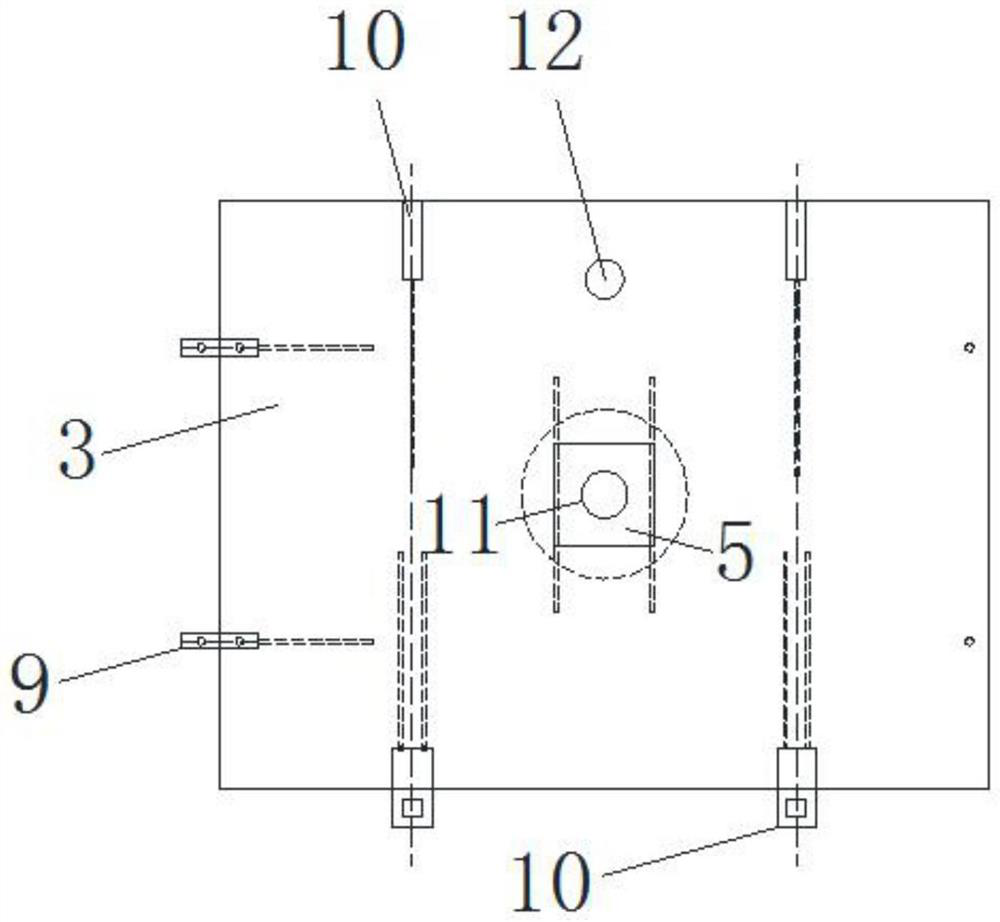

[0040] The end of each soil nail anchor rod is fixed to the UHPC prefabricated panel 3 through a fixing bolt 6 and a backing plate 5 . A notch is provided on the prefabricated panel 3, and an installation hole 11 is arranged in the notch, and the fixing bolt 6 passes through the backing plate 5, and passes through the installation hole 11, and is fixed with the soil nail anchor rod 2. The UHPC prefabricat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com