Construction method of steel plate and concrete composite structure

A steel plate concrete and composite structure technology, applied in bridge parts, erection/assembly of bridges, bridge materials, etc., can solve the problems of prolonged construction period, inability to guarantee construction quality, low maintenance costs in the later period, etc., to improve the bearing capacity and stiffness of bridges , The overall work performance is good, the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

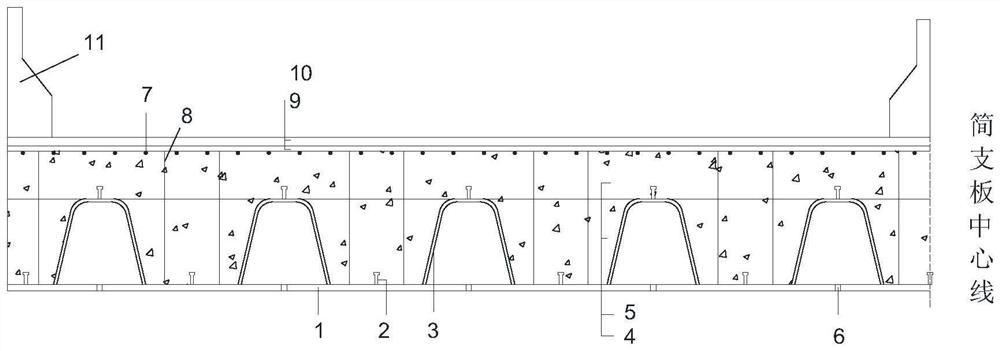

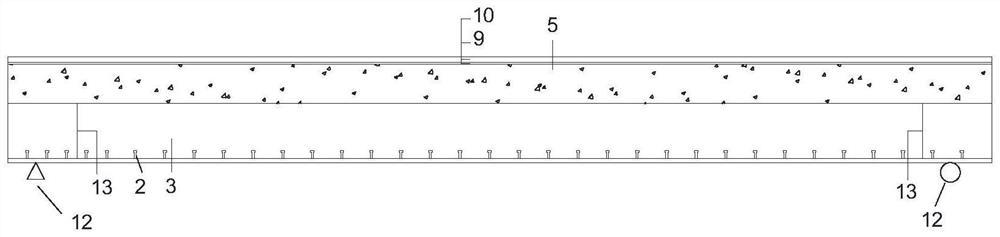

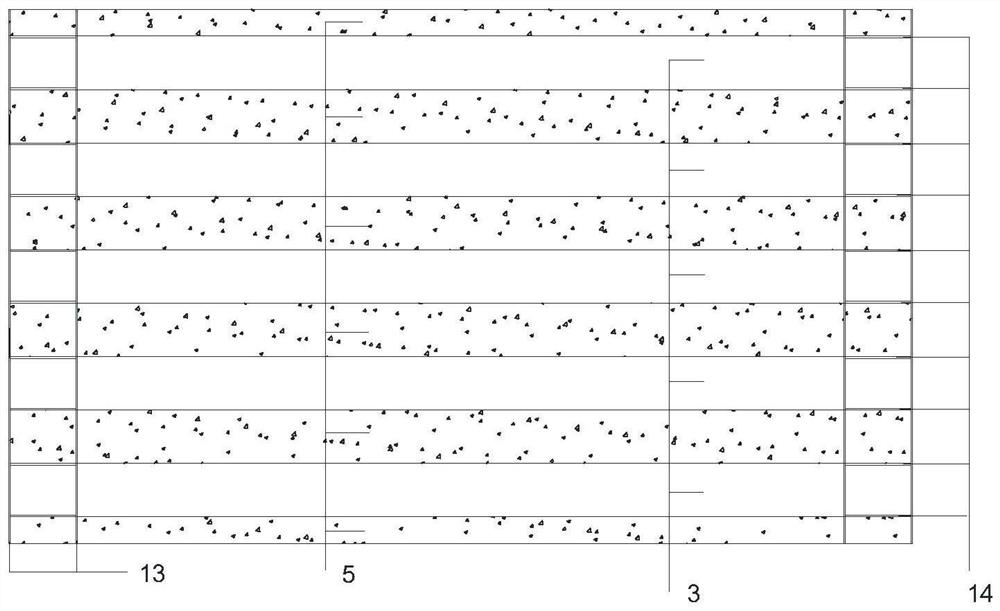

[0034] A steel plate concrete composite structure and construction method, the structure includes support, bottom steel plate, U ribs, studs, horizontal bridge end plate, longitudinal bridge end plate, stirrups, cast-in-situ main girder of the first floor from bottom to top Concrete, cast-in-place concrete for the main girder of the second floor, bridge deck pavement and guardrail, including the following steps:

[0035] (1) Through finite element calculation and analysis, the specific dimensions of each part required for the composite structure are calculated according to the specific span and width requirements of the slab bridge with the limit state method of bearing capacity, including (the size of steel plates, U ribs, and studs, pouring in stages Concrete thickness, support form, specifications, etc.).

[0036] (2) Weld the bottom steel plate, U ribs, studs, and end plates on both sides in the beam field to make it a whole. For structures with large width requirements, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com