Melt-blown medical protective material with cattail vein structure as well as preparation method and application of melt-blown medical protective material

A protective material and technology of cattail leaf veins are applied in the field of melt-blown medical protective material of cattail leaf vein structure and its preparation field, which can solve the problem that polylactic acid material is difficult to achieve balance in the field of sound insulation and noise reduction, and achieves good biodegradable characteristics, good The effect of water absorption and good hydrophilic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

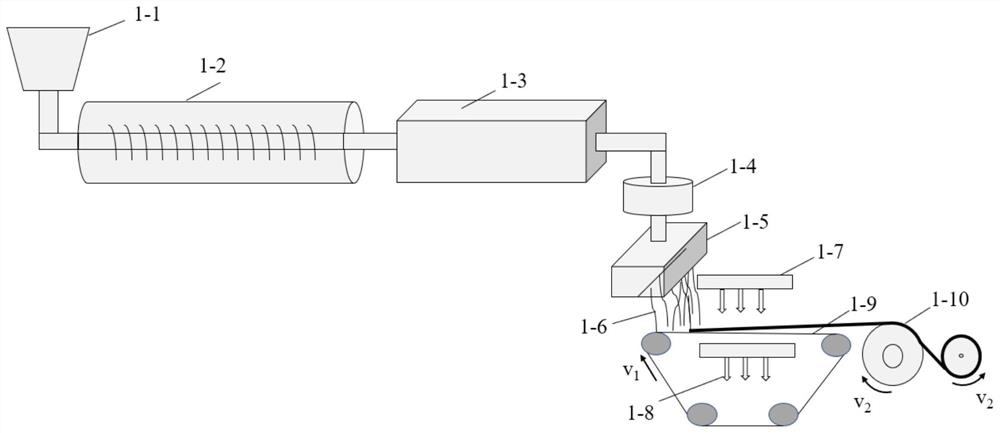

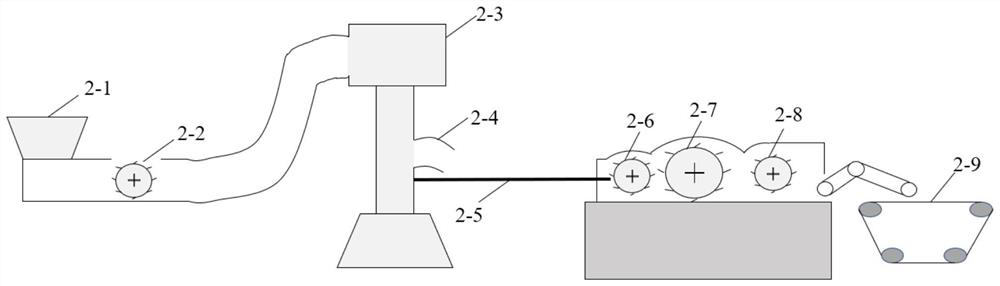

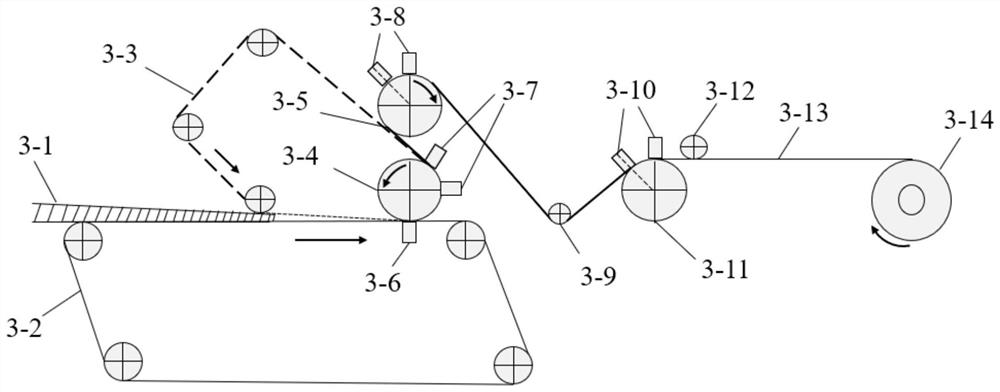

[0039] A method for preparing a melt-blown medical protective material with a cattail vein structure, the forming process is as follows figure 1 , figure 2 and image 3 As shown, the steps are as follows:

[0040] (1) Preparation process of hydrophilic modified polymer

[0041] First, polyethylene glycol particles with an average particle diameter of 2500nm and sodium dodecylsulfonate particles with an average particle diameter of 1000nm are blended in a mass ratio of 1:1, and then heated and melted in a water bath to make them Evenly distributed, the temperature of the water bath is 80°C, and then mixed with polylactic acid particles according to the mass ratio of 2:98.

[0042] Then, the polylactic acid particles with hydrophilic modified particles are sent into a granulator to obtain hydrophilic modified particles / polylactic acid slices.

[0043] (2) The process of preparing and forming a web of oriented fiber layers

[0044] Send the hydrophilic modified particles / po...

Embodiment 2

[0056] A preparation method of a melt-blown medical protection material with cattail vein structure, the steps are as follows:

[0057] The preparation method of this example is the same as that of Example 1, the difference is that in step (1) the mass ratio of polyethylene glycol and sodium dodecylsulfonate blended hydrophilic modified particles to polylactic acid raw material is 3 : 97 ratio mix.

[0058] The test results of its characteristics are shown in Table 1.

Embodiment 3

[0060] A preparation method of a melt-blown medical protection material with cattail vein structure, the steps are as follows:

[0061] The preparation method of this example is the same as that of Example 1, the difference is that in step (1) the mass ratio of polyethylene glycol and sodium dodecylsulfonate blended hydrophilic modified particles to polylactic acid raw material is 4 : 96 ratio mix.

[0062] The test results of its characteristics are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com