Preparation method of full-dull cotton-like polyester fiber

A technology of fully matting polyester and polyester fibers, applied in the field of polyester fibers, can solve the problems of rough raw tow, poor double filament cohesion, and many broken ends, etc., to improve the degree of tow network, the fabric surface is flat, and the resource consumption can be avoided. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

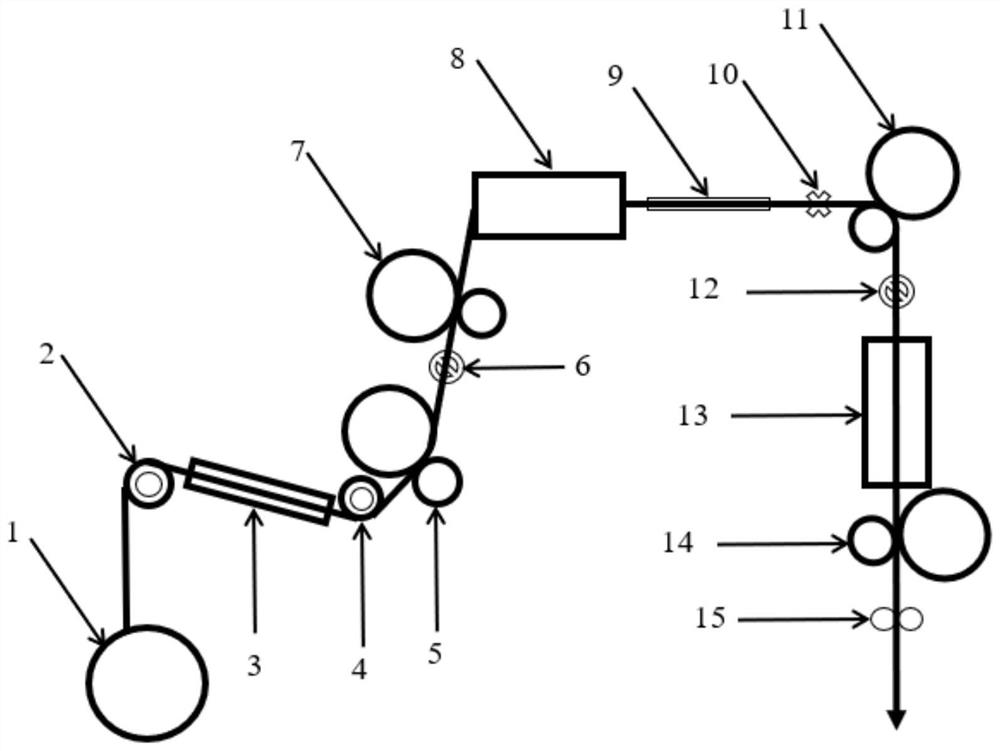

Method used

Image

Examples

Embodiment 1

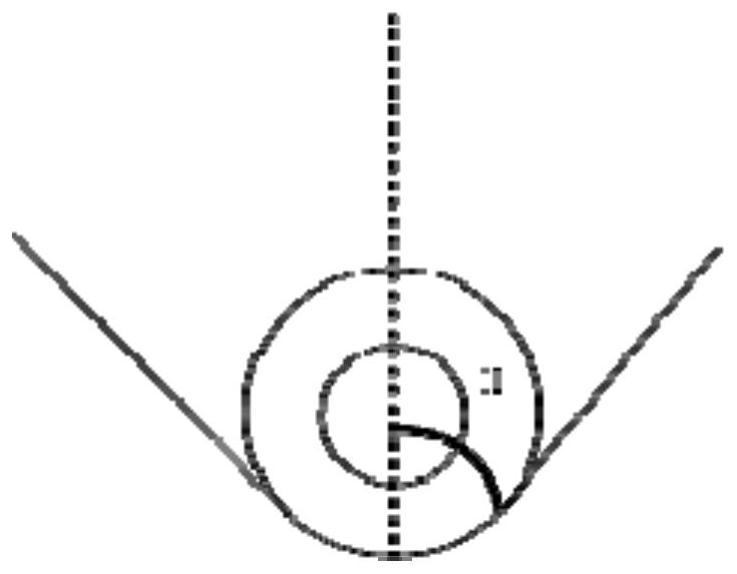

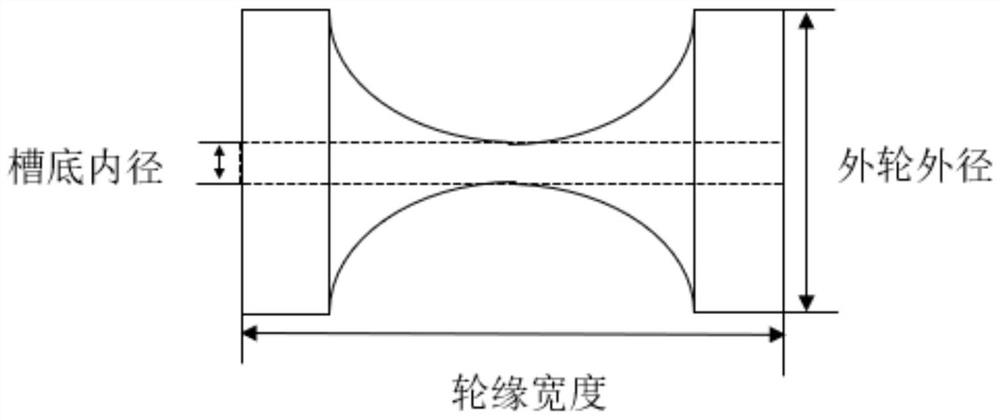

[0040] A kind of preparation method of full-dull cotton-like polyester fiber adopts the above-mentioned DTY texturing process, wherein the specifications of full-dull polyester POY and full-dull polyester FDY fibers are both 192dtex / 108f, and the content of titanium dioxide as a matting agent is 2.2wt%. Both the first wire guide and the second wire guide are wire guide wheels with the same shape and size, the material is ceramic, the surface hardness of the bottom of the groove is 1500HV, and the friction coefficient between the bottom of the groove and the tow is 0.20; image 3 As shown, the width of the godet wheel rim is 20 mm, the outer diameter of the outer wheel is 9.4 mm, and the inner diameter of the bottom of the groove is 6 mm; the tow is in contact with the bottom of the groove of the first wire guide and the second wire guide during running , driving the first yarn guide and the second yarn guide to rotate; the tow is wound 2 turns on the first wire feeding roller; ...

Embodiment 2

[0047] A kind of preparation method of full-dull cotton-like polyester fiber adopts the above-mentioned DTY texturing process, wherein the specifications of full-dull polyester POY and full-dull polyester FDY fibers are both 192dtex / 108f, and the content of titanium dioxide as a matting agent is 2.3wt%. Both the first wire guide and the second wire guide are wire guide wheels with the same shape and size, the material is ceramic, the surface hardness of the bottom of the groove is 1800HV, and the friction coefficient between the bottom of the groove and the tow is 0.20; The width of the wheel rim is 20mm, the outer diameter of the outer wheel is 9.4mm, and the inner diameter of the bottom of the groove is 6.2mm; the tow is in contact with the bottom of the groove of the first wire guide and the second wire guide during running, driving the The first yarn guide and the second yarn guide rotate; the tow is wound 2 times on the first feed roller; the inferior angle of the tow befo...

Embodiment 3

[0052] A kind of preparation method of full-dull cotton-like polyester fiber adopts the above-mentioned DTY texturing process, wherein the specifications of full-dull polyester POY and full-dull polyester FDY fibers are both 192dtex / 108f, and the content of titanium dioxide as a matting agent is 2.4wt%. Both the first wire guide and the second wire guide are wire guide wheels with the same shape and size, the material is ceramic, the surface hardness of the bottom of the groove is 1880HV, and the friction coefficient between the bottom of the groove and the tow is 0.22; The width of the wheel rim is 23 mm, the outer diameter of the outer wheel is 10.2 mm, and the inner diameter of the bottom of the groove is 7 mm; the tow is in contact with the bottom of the groove of the first wire guide and the second wire guide during running, driving the first wire guide A yarn guide and the second yarn guide rotate; the tow is wound 3 times on the first feed roller; the inferior angle of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com