Extraction method of Japan cypress essential oil

An extraction method, a technology of cypress essential oil, which is applied in the field of extraction of cypress essential oil, can solve problems such as complex process, achieve the effects of simplifying process, improving extraction yield, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

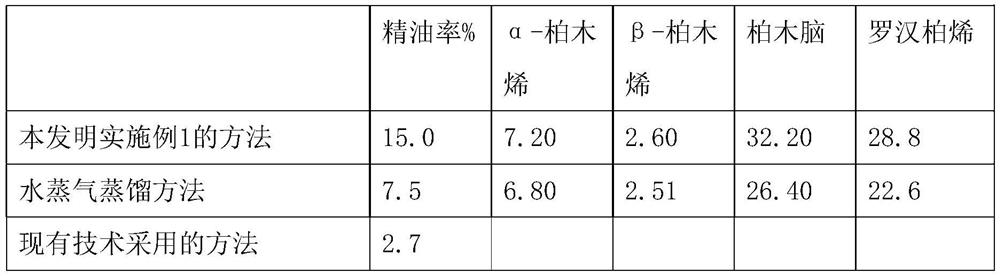

Examples

Embodiment l

[0037] A method for extracting cypress essential oil, comprising the following steps:

[0038] (1) Wash the cypress rhizomes and trunks, remove surface sand and soil impurities, then chop them into short wood chips, clean them with drinking water, dry them with a dryer to a water content of 5%, and crush them to 40% after drying. Purpose particle, obtain fine wood powder;

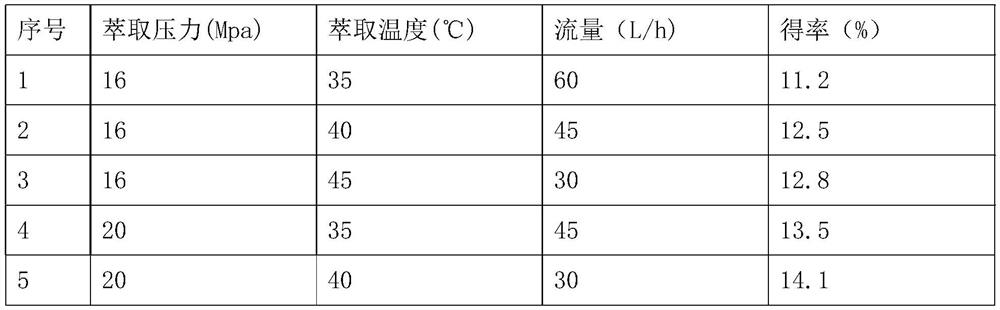

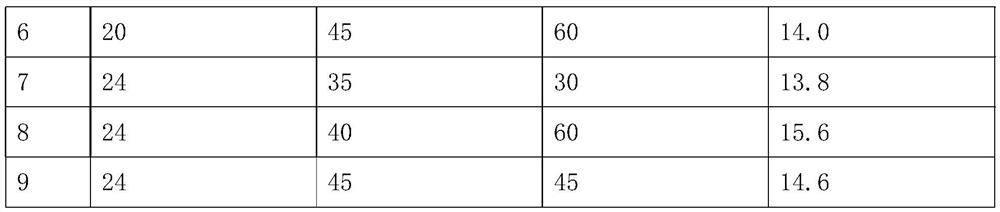

[0039] (2) Put the fine wood powder in a supercritical carbon dioxide extraction device to extract essential oil; set the extraction temperature to 30°C, the extraction pressure to 24Mpa, and the extraction time to 45min; the carbon dioxide flow rate to 55kg / h, the separation pressure to 4.5MPa, and the separation temperature At 45°C, a crude oil was obtained.

[0040] (3) The crude oil is distilled under reduced pressure to remove moisture, the vacuum degree is 0.095MPa, the distillation temperature is (90-95)°C, and the distillation time is 30min.

[0041] (4) The oil obtained by distillation under redu...

Embodiment 2

[0043] (1) Wash the cypress rhizomes and trunks, remove surface sand and soil impurities, then chop them into short wood chips, clean them with drinking water, dry them with a drier until the water content is 6%, and crush them to 20% after drying. Purpose particle, obtain fine wood powder;

[0044] (2) Put the fine wood powder in a supercritical carbon dioxide extraction device to extract essential oil; set the extraction temperature to 25°C, the extraction pressure to 20Mpa, and the extraction time to 1h; the carbon dioxide flow rate to 30kg / h, the separation pressure to 4.5MPa, and the separation temperature At 45°C, a crude oil was obtained.

[0045] (3) The crude oil is distilled under reduced pressure to remove water, the vacuum degree is 0.095MPa, the distillation temperature is (90-95)°C, and the distillation time is 30min.

[0046] (4) The oil obtained by vacuum distillation is removed through a 1 μm microporous membrane to obtain cypress essential oil.

Embodiment 3

[0048] (1) Wash the cypress rhizomes and trunks, remove surface sand and soil impurities, then chop them into short wood chips, clean them with drinking water, dry them with a drier until the water content is 7%, and crush them to 20% after drying. Purpose particle, obtain fine wood powder;

[0049] (2) Put the fine wood powder in a supercritical carbon dioxide extraction device to extract essential oil; set the extraction temperature to 30°C, the extraction pressure to 24Mpa, and the extraction time to 1h; the flow rate of carbon dioxide to 40kg / h, the separation pressure to 4.2MPa, and the separation temperature At 40°C, a crude oil was obtained.

[0050] (3) The crude oil is distilled under reduced pressure to remove water, the vacuum degree is 0.095MPa, the distillation temperature is (90-95)°C, and the distillation time is 30min.

[0051] (4) The oil obtained by distillation under reduced pressure is removed by a 5 μm microporous membrane to obtain cypress essential oil....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com